With plastic pollution reaching a breaking point, the fashion industry has a major responsibility. Enter recycled polyester, the most promising solution to turn plastic waste into a wearable asset. This is your guide to understanding why your next purchase should be a vote for a greener future.

What is recycled Polyester

Recycled polyester (often called rPET) is a fabric made from used plastics like old plastic bottles that have been melted down and re spun into new fibers. This process gives plastic waste a second life in textiles reducing the demand for new petroleum based polyester.

Difference from virgin polyester

The difference is simple: Virgin polyester is brand new, made from oil. Eco friendly polyester gives plastic waste a second life. They perform the same, but rPET is far kinder to the planet. It’s the smarter, more sustainable choice for your closet.

Polyester recycling

Polyester recycling involves turning plastic waste into new fabric. There are two main methods for this process: Mechanical and Chemical recycling.

Mechanical Recycling

We have a secret to share about the plastic you throw away. The secret isn’t magic. It is mechanical recycling and it’s surprisingly simple. This is how we can turn trash into a whole new material without changing its core identity. Get ready to see how your plastic bottle gets a simple, physical makeover.

Let’s go behind the scenes to see how it’s made.

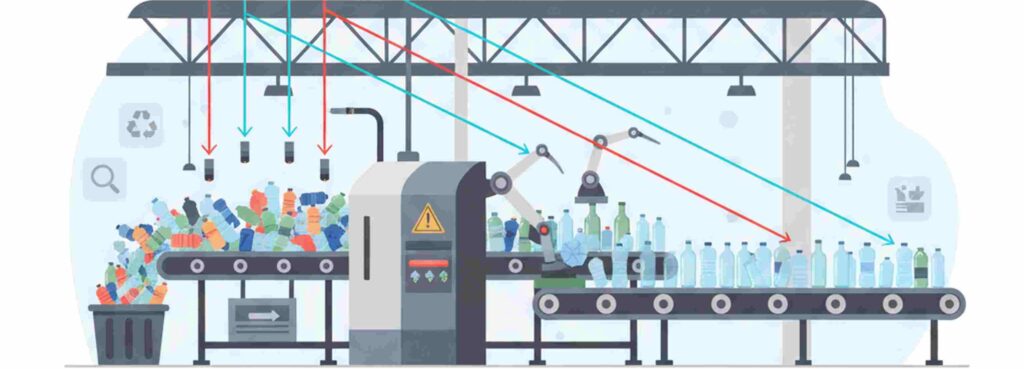

Step 1: Collection

You drop a bottle in the bin. A simple act right? But that’s just the beginning. The real journey starts when a truck scoops it up and it’s sent on its great adventure.

Step 2: Sorting

Now for the party! All the plastic arrives at a massive facility. Here, high-tech lasers and machines sort it. They separate the PET from everything else. Think of it as the ultimate bouncer, only allowing the right type of plastic in.

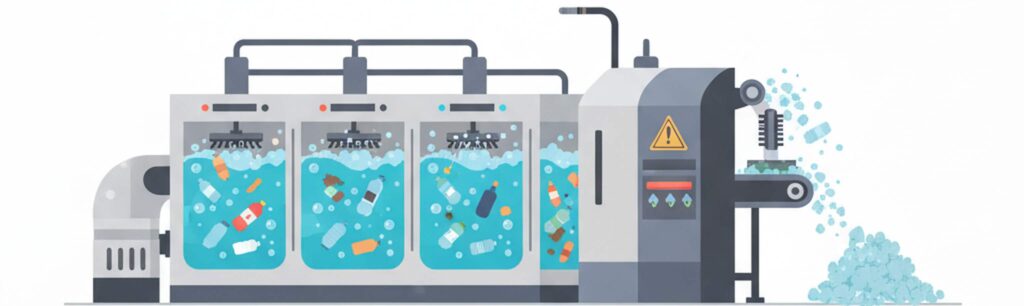

Step 3: Cleaning

Ready for a bath, before its big transformation, that plastic gets a deep clean. All the leftover junk and labels are washed away. This makes sure the final product is fresh and ready for its new life.

Step 4: Shredding

The most satisfying step, now clean plastic is sent through a giant shredder. Imagine a massive cheese grater turning your old bottle into tiny, uniform flakes.

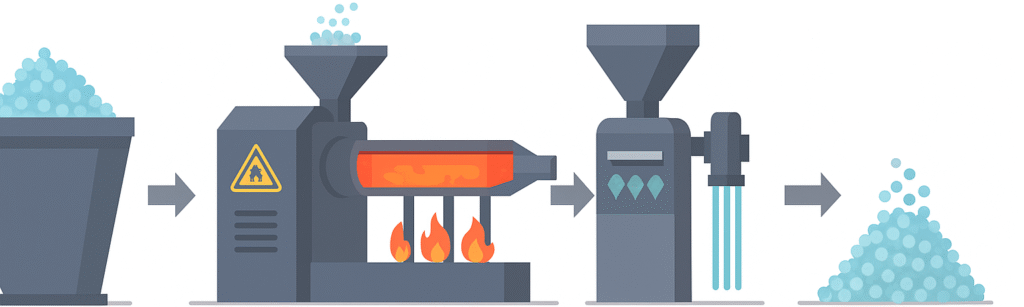

Step 5: Melting & Reforming

This is where the magic happens. The flakes are heated and melted down. The molten plastic is then forced through a machine to create long, uniform strands. Finally, these strands are cut into pellets, the tiny building blocks of a new product.

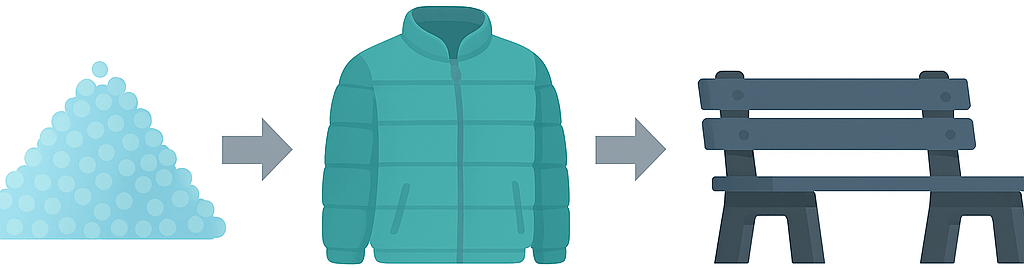

Step 6: Rebirth

What comes next is the grand finale. Those little pellets are now a blank canvas, ready to become almost anything. A new life awaits maybe a brand-new jacket, a durable bench or another bottle, proving that every piece of plastic can have a second chance.

The rebirth of that bottle is a great first step but it doesn’t solve every problem. There are some limitations to this simple makeover that you need to know.

Limitations of Mechanical Recycling:

Quality degradation:

Every time we melt and reshape plastic, it gets a little weaker. The long plastic molecules break into smaller ones. This is why a recycled bottle can’t become a bottle forever, and often gets turned into a park bench or carpet instead. It’s a downgrade, not a fresh start.

Color inconsistency:

The colored plastic bottles used in the process can lead to color variations in the recycled polyester chips, making consistent dyeing more challenging and potentially increasing the use of chemicals.

The micro plastic problem

The recycling process itself has a dirty secret. The shredding and washing that cleans the plastic also releases invisible micro plastic particles into our water. So even while we’re doing good we might be fueling a different kind of pollution.

The economic squeeze

What if we told you it’s often cheaper to make brand new plastic from oil than to use the recycled stuff? The sad truth is that a weak market demand for recycled plastic is a giant roadblock, slowing down the entire effort.

So, what happens to the plastics that are too complex, too dirty or too weak for that simple physical makeover? This is where the next evolution of recycling rewrites the rules completely. It’s time for a fresh start.

Chemical Recycling

You think you know what happens when you recycle plastic. But what if there’s more to the story than we think? Get ready to learn the whole story.

The future of recycling isn’t just about reusing old plastic. It’s about giving it a perfect fresh start. Welcome to the world of chemical recycling.

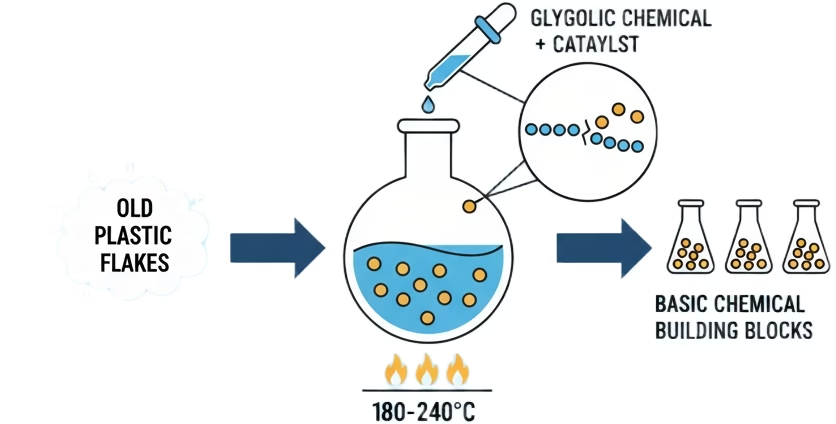

Step 1 Glycolysis

Think of a bottle as a pearl necklace. Instead of just melting it down, we use chemistry to precisely snip the string, freeing every single pearl. This process, called glycolysis, completely breaks the plastic into its most basic, tiny molecules or monomers

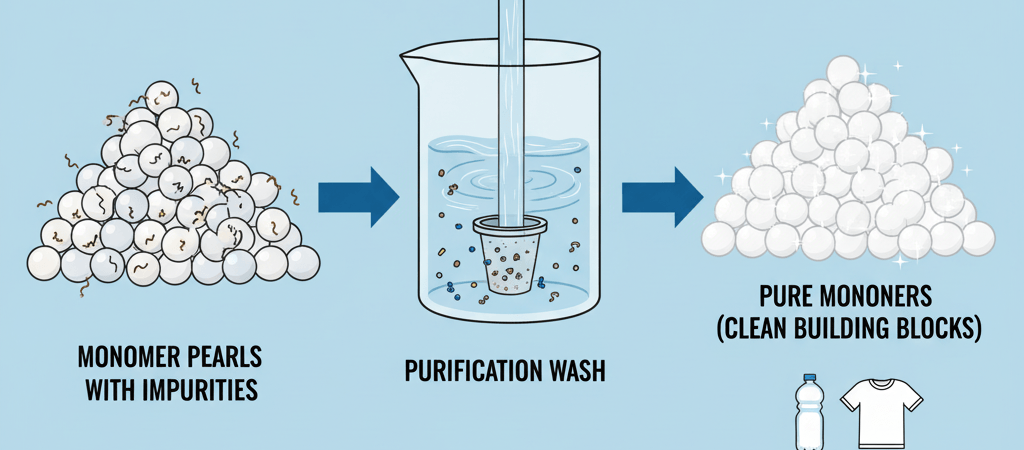

Step 2 Depolymerize to BHET

Now that the plastic is just a pile of pristine pearls, we can wash away all the dirt, colors, and baggage from its former life. Any imperfections are left behind, and what remains are pure monomers, the perfectly clean building blocks of new plastic.

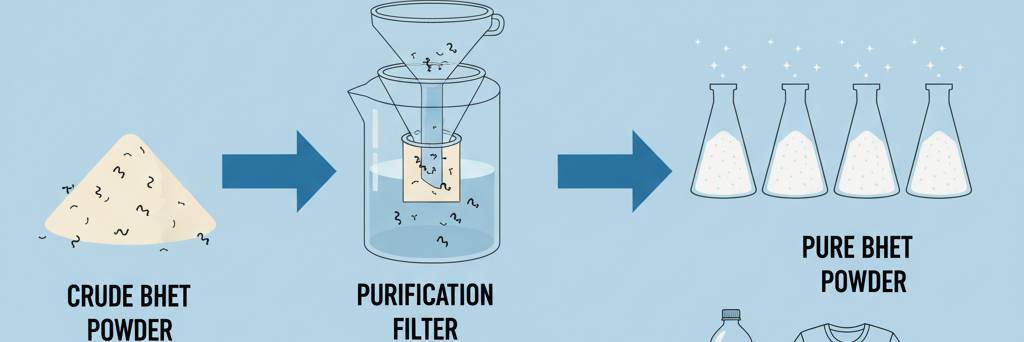

Step 3 Purification:

These pure building blocks are a blank canvas. We can string them back together, assembling brand-new plastic with the exact same strength and purity as plastic made from new oil. This isn’t a downgrade; it’s a perfect recreation.

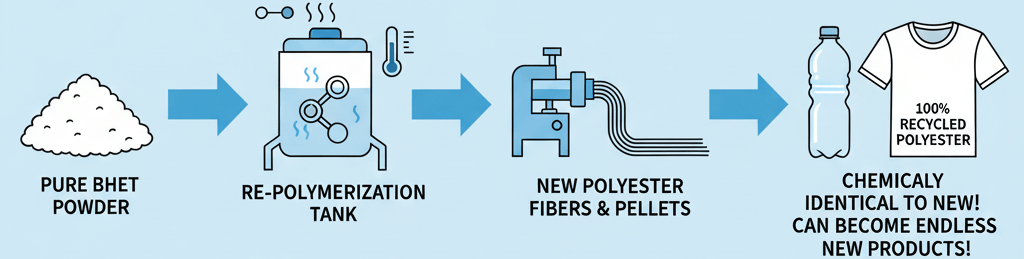

Step 4 New, High-Quality Polyester

Because the plastic is rebuilt from scratch, the material can be recycled again and again, endlessly, without losing any quality. It’s the true closed-loop cycle, giving every bottle a happily-ever-after without an expiration date.

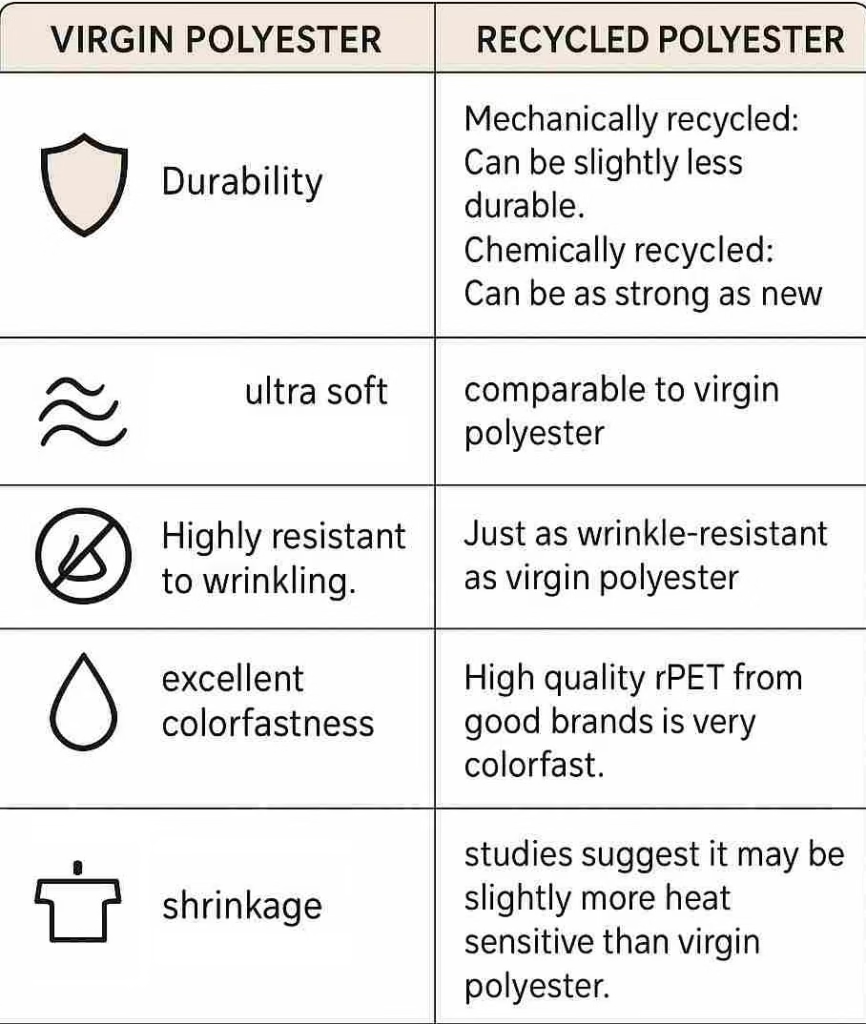

Quality and performance of recycled Polyester V/s Virgin

Recycled polyester is better for the environment than new polyester. For many items, its performance is very similar. With high-quality material, the difference is almost unnoticeable.

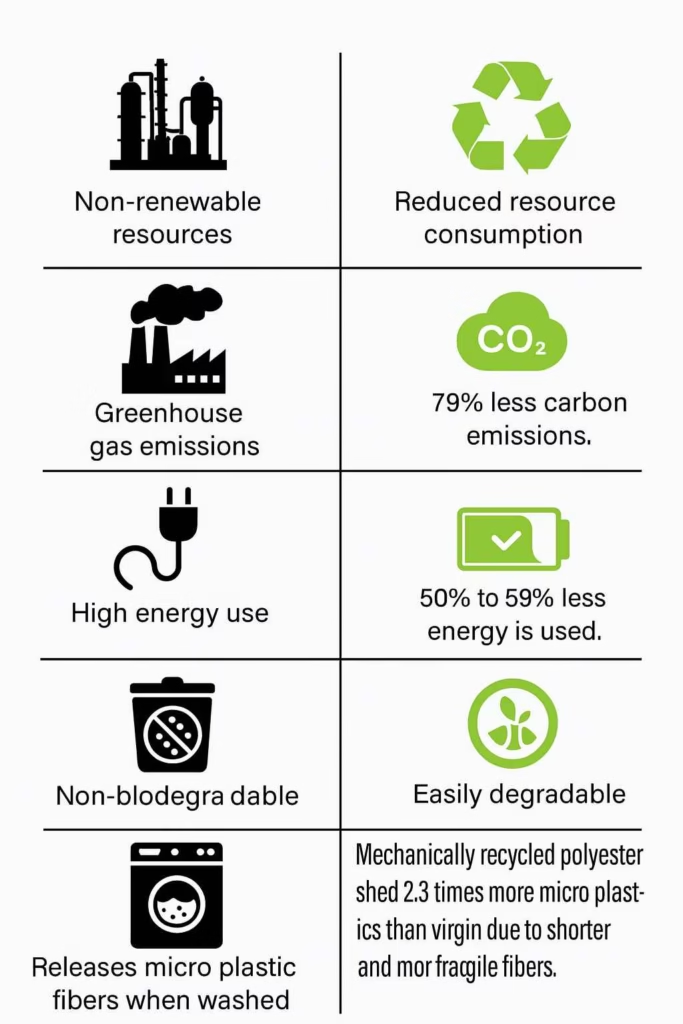

Environmental impact of recycled Polyester vS Virgin

Is Recycled Polyester worth it?

Yes, recycled polyester is often worth paying for, especially for buyers who prioritize environmental benefits. While it typically costs more than new polyester, the extra expense contributes to important sustainability goals.

You should choose rPET when:

- Your primary concern is minimizing your environmental footprint.

- You want to reduce plastic waste in landfills and oceans.

- You need a durable, high-performance product with a lower impact.

- You want to support brands that prioritize sustainability.

You might choose virgin polyester when:

- Your primary concern is cost.

- Maximum durability.

- Products with frequent washing.

How to spot genuine recycled polyester (avoid green washing)

For maximum safety, always choose certified recycled polyester. For clothing and other textiles that come in contact with the skin, look for one of the following certifications:

- Global Recycled Standard (GRS): This is one of the most comprehensive standards. It verifies the recycled content of a product and ensures responsible environmental and social practices are used during production. GRS has different tiers, with the highest requiring products to contain 95–100% recycled material.

- OEKO-TEX® Standard 100: This is a comprehensive certification that tests for over 100 harmful substances. It is one of the most reliable indicators that the finished product is safe for human health.

- Bluesign®: This standard focuses on the environmental and human health impacts of the entire textile manufacturing process.

How to buy specific recycled polyester products:

Active wear (leggings, workout tops)

- Prioritize durability: Choose reputable brands with clear quality standards.

- Look for certifications: Labels like GRS or REPREVE® ensure verified recycled content.

- Don’t mistake wicking for breathability: For comfort, look for engineered weaves or blends, not just 100% rPET.

Outerwear (jackets, fleeces)

- These items aren’t washed often, reducing micro plastic concerns.

- Look for products that feature a high percentage of rPET.

- High-quality rPET outerwear is very durable and weather-resistant.

T-shirts and casual wear

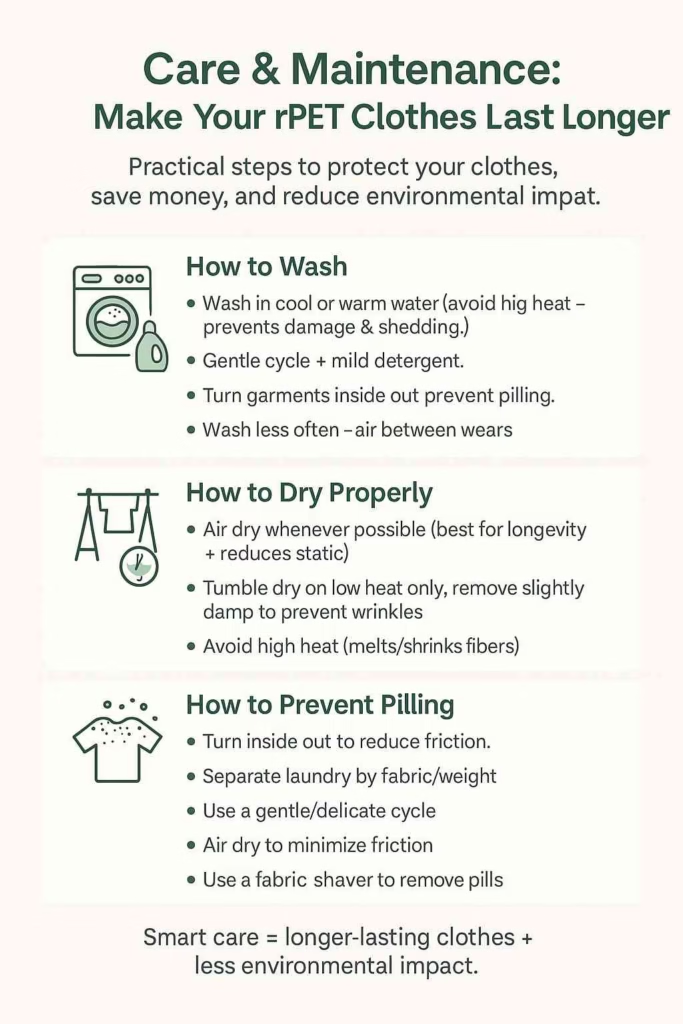

- Be aware of micro plastics. These items are washed often, so shedding is a concern.

- Consider blends. Cotton blends can offer better breathability and feel.

- Choose wisely. Inexpensive rPET from fast-fashion brands may be “green washing”

Home goods (bedding, curtains):

- Enjoy comparable quality. High-quality rPET home goods perform just like new polyester.

- Check for safety and content. Look for certifications like OEKO-TEX® and GRS.

- Balance price and quality. Be wary of very low prices, which might signal lower-quality material.

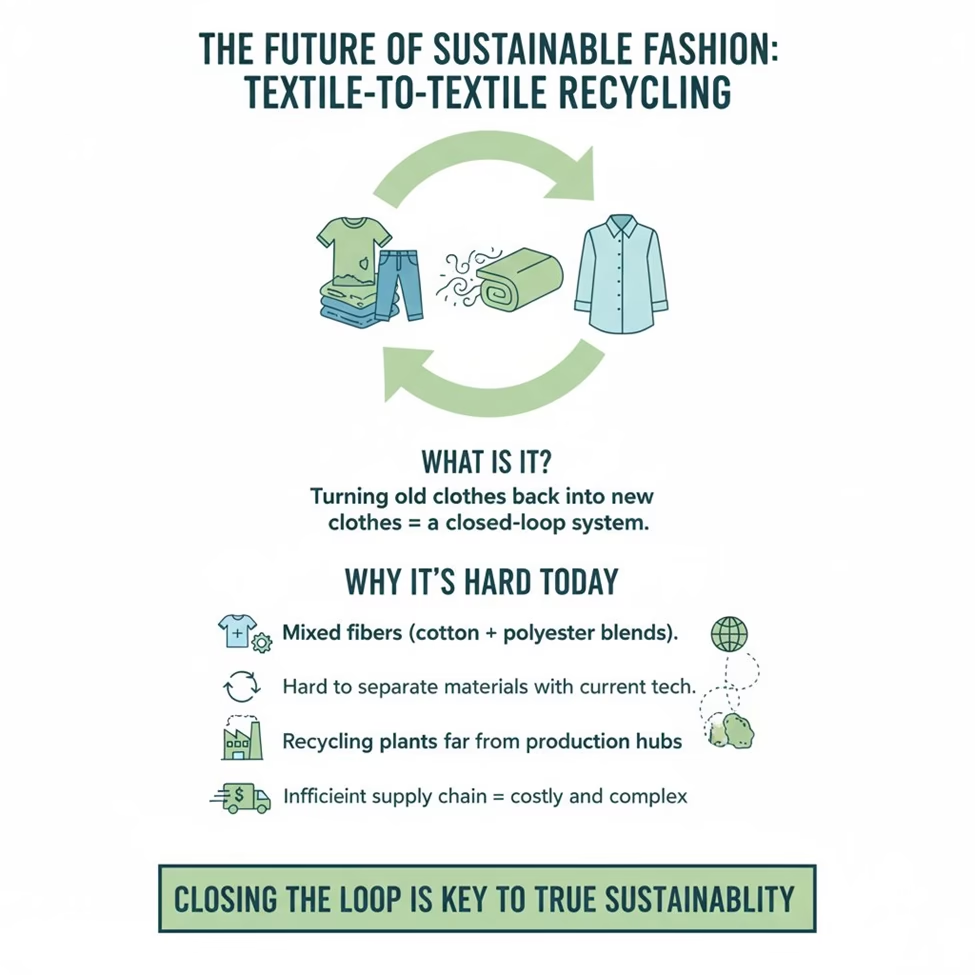

Future of sustainable fashion:

The real future of sustainability lies in building a true circular economy for textiles where old garments are transformed into new ones, closing the loop beyond plastics.

Innovations driving a sustainable future

Textile to Textile Recycling

This technology involves chemically breaking down old polyester clothes to create new ones.

This process can eventually create a closed loop, where materials are reused endlessly.

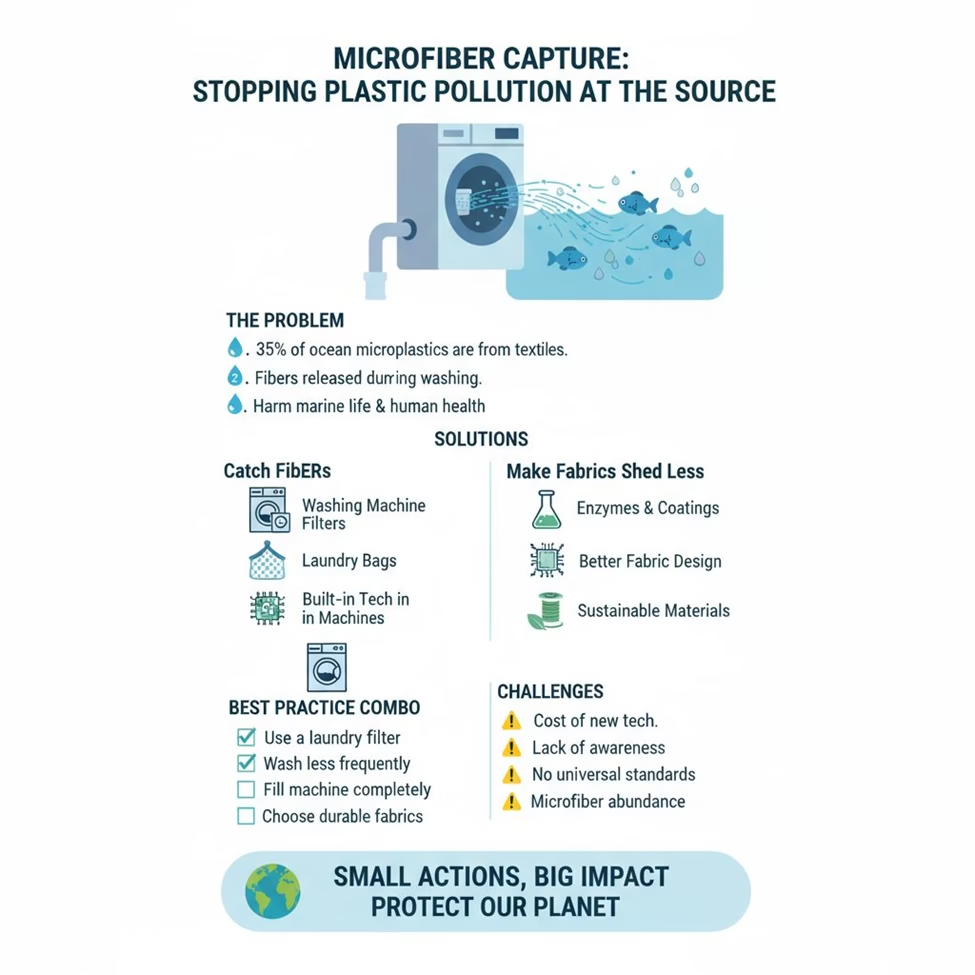

Microfiber capture:

These devices, like filters for washing machines or special fabrics, prevent tiny plastic fibers from shedding into water ways during laundry. This technology directly addresses one of the biggest environmental drawbacks of polyester and other synthetic fabrics: micro plastic pollution.

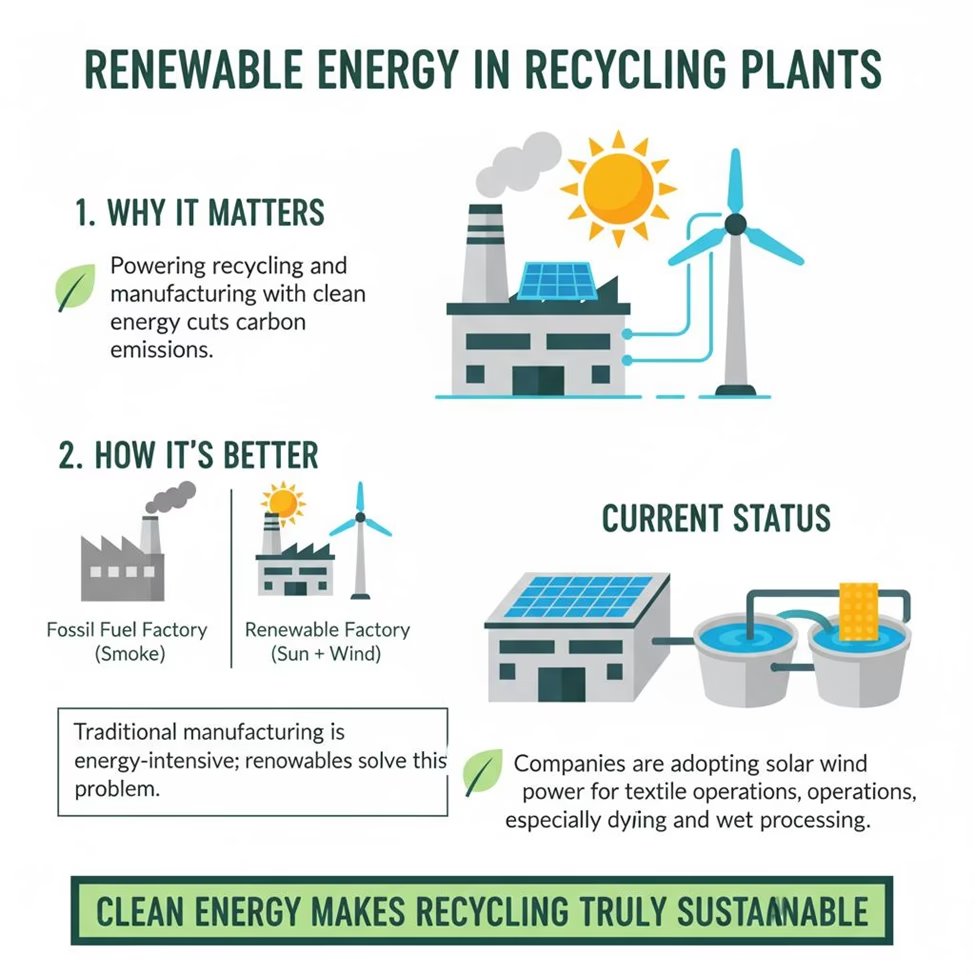

Renewable energy in recycling plants

Powering recycling and manufacturing facilities with clean energy significantly reduces the carbon footprint of production.

FAQ

Is recycled polyester really ecofriendly or green washing

Recycled polyester (rPET) is more eco-friendly than virgin polyester but is not a perfectly sustainable material and can be used for green washing. It’s a better choice than new polyester, but not a perfectly sustainable one.

Does it shrink, fade or loose shape

No, it is highly resistant to shrinking, fading, and losing shape, just like virgin polyester. This is because it is made from the same durable, synthetic plastic fibers that resist moisture absorption.

Is it safe for kids

No, recycled polyester (rPET) is not the safest material for children. For general clothing, natural fibers are often the safest and most breathable choice.

Is recycled polyester good for sportswear?

Yes, recycled polyester is very good for sportswear, offering the same high-performance qualities as virgin polyester. Major brands like Patagonia have successfully used it in active wear for decades.

How long does it last compared to cotton

Recycled polyester generally outlasts cotton, particularly with frequent washing and heavy use. Its synthetic fibers offer superior durability, retaining shape and color much better over time.

Does it pill or scratch easily

High-quality, tightly woven recycled polyester is very resistant to pilling, much like premium virgin polyester. Blended with natural fibers like cotton or wool is more likely to pill

Does it feel cheap?

Not necessarily. High-quality recycled polyester (rPET) can feel and perform just as well as virgin polyester, especially when made using advanced recycling processes.

However, the quality can vary depending on the recycling method, the source of the plastic waste, and the manufacture.