Glass Reinforced Polyester (GRP): Properties, Uses, Safety & Grades

Glass reinforced polyester (GRP) is a composite material formed by combining glass fibers with a polyester resin matrix to achieve structural strength, durability, and resistance to environmental stress. It is widely used across construction, industrial, marine, and electrical sectors where corrosion resistance and weight reduction are critical.

Understanding GRP requires evaluating not only its performance advantages, but also its safety considerations, material limits, and suitability for specific technical applications.

What Is Glass Reinforced Polyester?

Glass reinforced polyester (GRP) is an engineered composite material designed to deliver structural performance where conventional materials such as steel, aluminum, or unreinforced plastics are inefficient or impractical.

It exists to combine mechanical strength, corrosion resistance, and dimensional stability in applications exposed to moisture, chemicals, or electrical loads.

GRP is widely specified in industrial, infrastructure, marine, and electrical environments where long service life and predictable behavior are required.

The term GRP is often used interchangeably with fiberglass and fiber reinforced plastic (FRP), which creates confusion.

In practice, fiberglass refers to the glass fibers themselves, not the finished composite.

FRP is a broad category that includes many resin systems, such as epoxy or vinyl ester.

GRP is a specific subset of FRP that uses polyester resin as the matrix material.

Performance, cost, and durability vary significantly depending on this distinction.

GRP should be understood as a structural material system rather than a single product.

Its properties depend on fiber type, resin selection, and material grade, which is why specifications differ widely across industries. Clear definition at this level is essential before comparing GRP to metals or other composites.

Basic Definition in Plain Technical Language

Glass reinforced polyester is a composite material made of two integrated components: glass fibers that provide mechanical strength, and a polyester resin matrix that binds, protects, and transfers loads between the fibers.

The glass fibers carry tensile and structural forces, while the polyester resin maintains shape, resists environmental exposure, and distributes stress.

This combination solves the limitation of plastics being weak on their own and glass fibers being unusable without a binding medium, resulting in a material that is strong, lightweight, and stable under demanding operating conditions.

Why Polyester Resin Is Used Instead of Other Polymers

Polyester resin is used in GRP because it offers a balanced combination of performance, cost control, and processing reliability across large-scale industrial applications.

It provides adequate mechanical properties for most structural and enclosure uses without the higher costs associated with advanced resin systems.

Key functional reasons include:

- Predictable curing behavior suitable for high-volume production

- Strong resistance to moisture, corrosion, and many industrial chemicals

- Lower material and processing costs compared to epoxy or vinyl ester systems

These factors make polyester resin the preferred choice where long-term durability is required but extreme mechanical or thermal performance is not the primary driver.

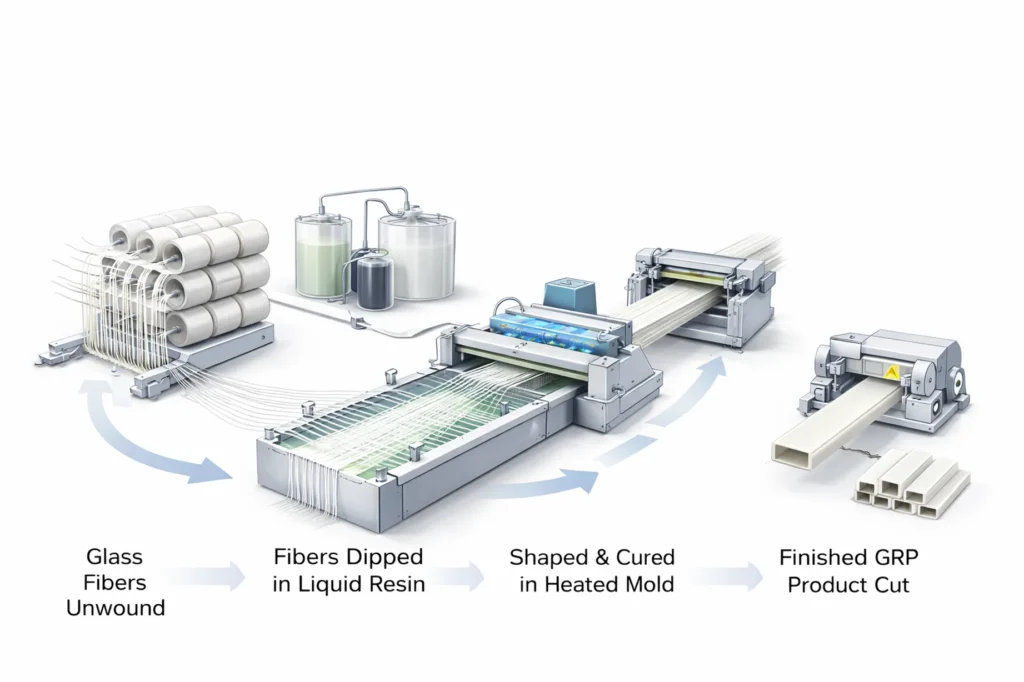

How Glass Reinforced Polyester Is Made

The way glass reinforced polyester is manufactured directly determines its mechanical strength, durability, and long-term reliability.

GRP is not a uniform material; its performance depends on how effectively the glass fibers are aligned, bonded, and protected by the resin matrix.

For engineers and procurement professionals, understanding the production logic helps explain why two GRP products with similar specifications can behave very differently in service.

Manufacturing choices influence load capacity, resistance to cracking, and consistency over time, rather than cosmetic or superficial characteristics.

Role of Glass Fibers in Structural Strength

Glass fibers are the primary load-bearing element in GRP.

They carry tensile and bending forces that the resin alone cannot withstand.

Strength is not uniform in all directions; it depends on fiber orientation, length, and distribution within the material.

When fibers are aligned with expected load paths, GRP can achieve high strength relative to its weight.

Poor alignment or inconsistent fiber placement reduces structural efficiency and can lead to premature failure under stress.

Fiber volume also matters. Higher fiber content generally increases stiffness and strength, but only when properly bonded.

Excess resin without sufficient reinforcement weakens the composite, while excessive fiber without proper wet-out creates voids and stress concentrations.

Polyester Resin Matrix and Fiber Bonding

The polyester resin matrix serves several critical functions beyond simply holding fibers in place. It transfers loads between fibers, maintains geometric stability, and protects the reinforcement from moisture, chemicals, and mechanical abrasion.

Effective bonding between resin and glass fibers is essential for durability. Weak bonding allows fibers to separate under load, leading to cracking, delamination, and loss of structural integrity.

The resin also controls failure behavior. Instead of sudden fracture, properly bonded GRP tends to show progressive damage, which is important in safety-critical applications where early warning is preferred over abrupt collapse.

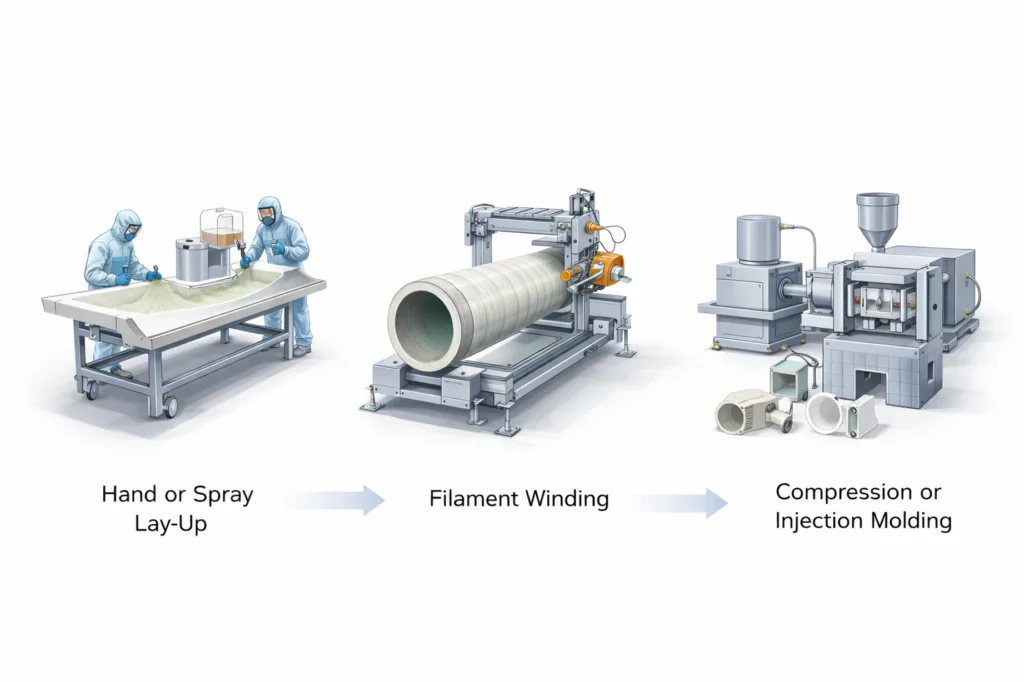

Common Manufacturing Methods (Lay-Up, Filament Winding, Molding)

Hand or Spray Lay-Up: Used for large or complex shapes where flexibility and low tooling cost are priorities.

Filament Winding: Fibers are precisely wound under tension, producing high strength in pressure vessels and pipes.

Compression or Injection Molding: Delivers consistent quality and tight tolerances for high-volume, standardized components.

Key Properties of Glass Reinforced Polyester

Glass reinforced polyester is selected based on a defined set of performance characteristics that directly affect structural reliability, service life, and operating cost.

Strength-to-Weight Ratio

GRP offers a high strength-to-weight ratio compared to many metals, which makes it valuable where weight reduction improves handling, installation, or system efficiency.

In platforms, panels, enclosures, and vehicle components, lower mass reduces structural support requirements and transport costs.

This advantage is most relevant in applications where loads are known and controlled.

GRP is not intended to replace steel in high-impact or highly dynamic load environments, but it performs reliably where stiffness and moderate strength are required without excessive weight.

Corrosion and Chemical Resistance

Resistance to corrosion is one of the primary reasons GRP is specified in aggressive environments.

It performs well in coastal, marine, waste water, and chemical processing settings where metals degrade rapidly without protective coatings.

GRP does not rust and is largely unaffected by moisture, salts, and many acids and alkalis.

This property becomes decisive in installations where maintenance access is limited or where long-term exposure would make metal alternatives costly to protect and repair.

Thermal and Electrical Properties

GRP provides effective electrical insulation, which is why it is widely used in electrical panels, cable trays, and switchgear enclosures.

Its thermal conductivity is low compared to metals, reducing heat transfer rather than serving as a heat-resistant material.

GRP maintains functional stability across typical industrial temperature ranges, but it is not designed for sustained high-temperature exposure.

Its value lies in insulation and safety, not extreme thermal performance.

Dimensional Stability and Longevity

When properly designed and manufactured, GRP maintains its shape and structural properties over long service periods. It resists moisture-driven swelling and corrosion-related deformation common in metals.

However, long-term performance depends on load levels, environmental exposure, and material grade. Poorly specified GRP can experience creep, fatigue cracking, or surface degradation over time.

Realistic lifespan expectations require matching the product grade to the application demands.

Types and Grades of Glass Reinforced Polyester

GRP grades exist because composite performance is engineered, not generic.

Fiber content, reinforcement structure, and resin formulation are adjusted to meet different mechanical, electrical, and environmental demands.

One GRP grade cannot be substituted for another without consequences.

Using the wrong grade does not only reduce efficiency; it can lead to premature cracking, loss of insulation performance, or structural failure under real operating loads.

GPO-1 Grade – Properties and Applications

GPO-1 is designed for applications that require a balanced combination of mechanical strength and electrical insulation without high structural stress.

It is commonly used in electrical boards, panels, and insulating components where dimensional stability and moderate load resistance are sufficient.

This grade prioritizes reliability and manufacturability over high load-bearing capacity.

GPO-2 Grade – Performance Characteristics

GPO-2 exists to address applications where GPO-1 reaches its mechanical limits.

It offers increased rigidity and strength, making it more suitable for components exposed to higher mechanical stress or vibration.

This grade is often selected in industrial electrical environments where material failure would create safety or operational risks, not just cosmetic damage.

GPO-3 Grade – High-Strength Applications

GPO-3 is used where structural reliability is critical and loads are consistently higher.

It is designed for load-bearing applications that require greater stiffness and resistance to deformation over time.

This grade supports structural components where failure would compromise system integrity, but it is still selected within defined design limits rather than extreme conditions.

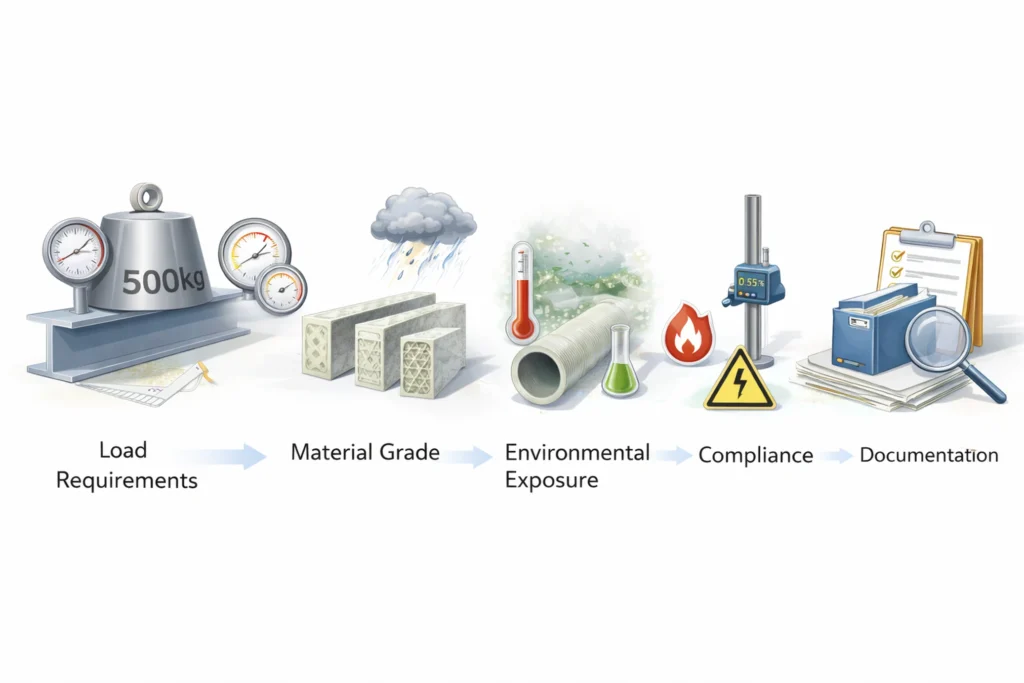

Choosing the Right GRP Grade for Your Project

- Load requirements: Static and dynamic forces the material must withstand

- Operating environment: Moisture, chemicals, temperature, and exposure duration

- Electrical or safety compliance: Insulation and regulatory requirements

- Service life expectations: Consequences of fatigue, creep, or long-term degradation

Incorrect grade selection typically results in delayed but costly failure rather than immediate malfunction.

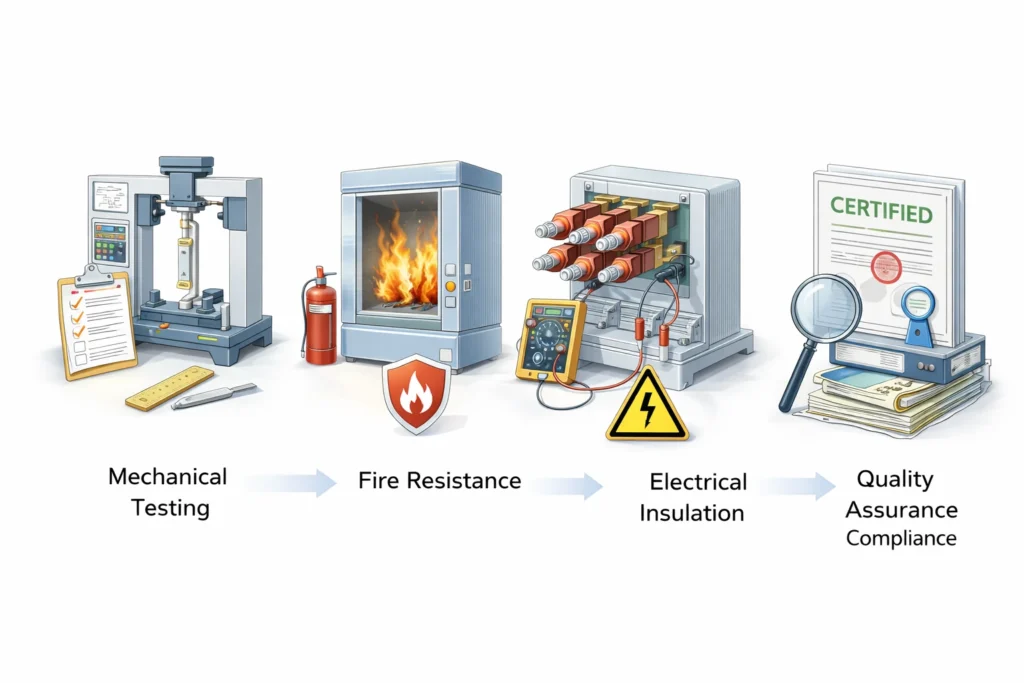

Standards, Testing, and Certifications for GRP

A GRP product can appear visually sound while still failing under load, heat, or electrical stress. Standards and certification exist to verify that material performance is consistent, predictable, and suitable for its intended environment.

For buyers and engineers, testing provides assurance that a product will perform over time, not just at installation.

Mechanical Testing Standards for GRP Materials

Mechanical testing confirms that GRP components meet minimum strength and stiffness expectations across production batches. This protects against hidden weaknesses caused by poor fiber distribution or inadequate bonding.

Consistent testing reduces the risk of sudden cracking, deformation, or progressive failure in service.

Fire Resistance and Safety Standards

Fire behavior matters where GRP is used in buildings, transport systems, or enclosed industrial spaces. Testing ensures that materials do not contribute excessively to flame spread or smoke generation. Compliance supports safer evacuation conditions and helps limit damage during fire incidents without overstating fire resistance.

Electrical and Insulation Testing Standards

Electrical testing verifies that GRP maintains reliable insulation under normal operating conditions.

This is critical in switchboards, enclosures, and cable management systems where insulation failure can lead to short circuits or equipment damage.

Standards help ensure performance remains stable over the product’s service life.

Quality Assurance and Compliance Requirements

Compliance requirements protect buyers by enforcing traceability, material consistency, and accountability across the supply chain.

Documented quality systems reduce variability between shipments and support corrective action if issues arise.

This enables informed procurement decisions based on verified performance rather than assumptions.

Common Uses of Glass Reinforced Polyester Across Industries

Glass reinforced polyester is adopted across industries where material performance must remain stable under environmental exposure, mechanical load, and long service cycles.

Its use is driven by a combination of corrosion resistance, structural efficiency, and electrical insulation rather than aesthetic or short-term cost factors.

Construction and Infrastructure Applications

In construction and infrastructure, GRP is used for panels, gratings, covers, cable trays, and structural profiles.

Its resistance to moisture, salts, and urban pollutants makes it suitable for bridges, walkways, and utility installations.

The low weight of GRP reduces installation effort while maintaining adequate load-bearing capacity for non-primary structural elements.

Automotive, Marine, and Transportation Uses

Transportation sectors use GRP where weight reduction directly improves efficiency and handling.

In automotive and rail applications, it is used for body panels, housings, and interior components that require dimensional stability and impact tolerance.

In marine environments, GRP performs reliably in hull sections, decks, and fittings due to its resistance to water ingress and corrosion.

Industrial Tanks, Pipes, and Enclosures

GRP is widely specified for storage tanks, piping systems, and protective enclosures in industrial facilities.

Chemical resistance makes it suitable for wastewater treatment, chemical processing, and coastal installations.

Electrical insulation properties support its use in control cabinets and equipment housings, where long-term reliability and reduced maintenance are critical.

Glass Reinforced Polyester vs Fiberglass vs Other Composites

Material comparisons matter because performance differences appear under load, exposure, and time not at first inspection.

GRP sits between basic reinforced plastics and high-end composites, offering a balance of durability, cost control, and predictable behavior.

The distinctions below focus on decision impact rather than material marketing.

GRP vs Traditional Fiberglass — What’s the Difference?

The confusion between GRP and fiberglass is largely semantic.

Fiberglass refers to the glass fibers as a reinforcement material, not a finished product.

GRP is the completed composite system where glass fibers are combined with a polyester resin matrix to deliver structural performance.

When people say “fiberglass parts,” they usually mean GRP.

The practical difference lies in specification control: GRP implies defined grades, tested properties, and predictable performance, whereas “fiberglass” is an informal term that does not guarantee consistency or compliance.

GRP vs Carbon Fiber — Cost vs Performance

Carbon fiber composites deliver higher stiffness and strength at significantly lower weight, but at a much higher cost and with stricter processing requirements.

GRP is selected where extreme performance is unnecessary and where durability, corrosion resistance, and electrical insulation matter more than maximum strength.

For most industrial, infrastructure, and enclosure applications, carbon fiber offers little practical advantage relative to its cost.

GRP fills the performance gap where metals are excessive and advanced composites are unjustified.

When Metal Outperforms GRP (And When It Doesn’t)

Metal outperforms GRP in applications involving very high temperatures, sharp impact loads, or continuous heavy structural stress.

Steel and aluminum also provide better performance where precise tolerances and ductility under overload are critical.

GRP performs better in corrosive environments, electrically sensitive installations, and weight-sensitive systems.

The decision is not material superiority, but suitability.

Misapplication in either direction leads to premature failure or unnecessary cost.

Is Glass Reinforced Polyester Safe?

Glass reinforced polyester is considered safe in normal use and installed applications when handled according to established industrial practices.

Safety considerations are primarily relevant during manufacturing, cutting, or modification processes rather than during service life.

Understanding where real risks exist helps organizations apply appropriate controls without overstating hazards or avoiding the material unnecessarily.

Health Risks During Manufacturing and Cutting

During manufacturing or on-site cutting, GRP can release dust and resin particles.

These are not unique to GRP but are common to many composite and construction materials.

Potential risks include skin irritation or respiratory discomfort if basic protective measures are ignored. These risks are manageable and well understood within industrial environments, and they do not indicate inherent toxicity of the finished product.

Glass Fiber Dust Exposure Explained

Glass fiber dust can be generated when GRP is drilled, cut, or sanded.

The fibers are mechanically irritating rather than chemically hazardous.

Short-term exposure may cause itching or irritation to the skin, eyes, or throat.

Long-term exposure risks are minimized when dust control measures are used, as the fibers are not soluble or bioactive in the way some hazardous dusts are.

Safety Standards and Workplace Protections

Established safety standards address GRP handling through ventilation, dust extraction, and personal protective equipment.

These measures are routine in fabrication and installation environments.

Compliance ensures worker safety while allowing GRP to be used without restriction in finished structures.

When controls are applied correctly, GRP presents no greater risk than other widely accepted construction materials.

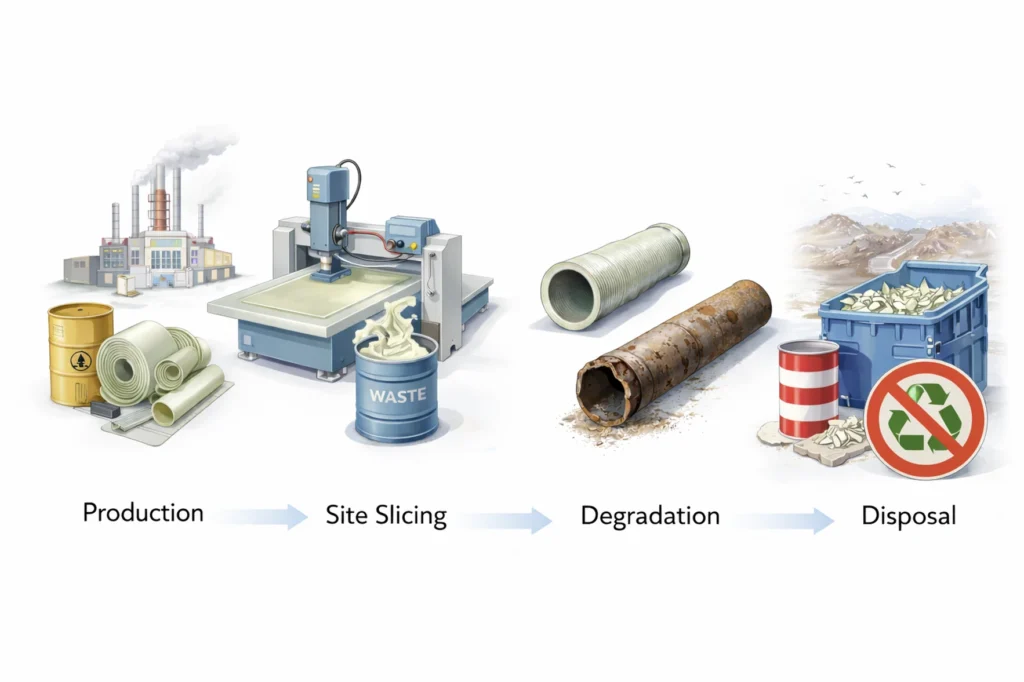

Environmental Impact of Glass Reinforced Polyester

Recyclability and Waste Challenges

Glass reinforced polyester presents challenges at end of life because it is a thermoset composite.

Once cured, it cannot be remelted or reshaped, which limits conventional recycling options.

Mechanical recycling is possible but typically results in downcycled material with reduced performance. As a result, disposal planning and waste reduction during fabrication are important considerations for large-scale or regulated projects.

Long-Term Environmental Footprint

From a service-life perspective, GRP offers durability that reduces replacement frequency and maintenance-related emissions.

Its resistance to corrosion and environmental degradation often leads to longer operational life compared to metals in aggressive environments.

While production and disposal impacts exist, extended service life and reduced maintenance can offset some environmental costs when GRP is specified appropriately.

Advantages of Glass Reinforced Polyester

Where GRP Is the Best Material Choice

- Corrosion resistance in aggressive environments

GRP performs reliably in coastal, chemical, wastewater, and high-humidity settings where metals require coatings, cathodic protection, or frequent maintenance. - High strength relative to weight

The material supports structural and semi-structural applications while reducing handling, transport, and installation loads compared to steel or concrete. - Electrical insulation and safety

GRP is well suited for electrical panels, enclosures, and cable management systems where conductivity presents operational or safety risks. - Low maintenance over long service life

Resistance to rust, rot, and moisture-driven degradation reduces inspection, repair, and replacement cycles in long-term installations. - Design flexibility without performance compromise

Complex shapes, integrated features, and tailored thickness can be achieved without secondary fabrication, supporting efficient system-level design. - Predictable performance when properly specified

Standardized grades and tested properties allow GRP to be selected with confidence for defined load and exposure conditions.

GRP is most effective when durability, environmental resistance, and lifecycle cost matter more than extreme strength or high-temperature performance.

Limitations and Disadvantages of Glass Reinforced Polyester

Structural Limits and Failure Scenarios

Glass reinforced polyester has defined structural limits that must be respected in design.

It does not perform well under sharp impact loading or sustained high stress beyond its rated capacity. Long-term creep can occur if loads are underestimated, leading to gradual deformation rather than immediate failure.

Poor fiber orientation, inadequate bonding, or incorrect grade selection increase the risk of cracking, delamination, or loss of stiffness over time.

Situations Where GRP Is a Poor Choice

GRP is not suitable for applications involving continuous high temperatures, direct flame exposure, or heavy dynamic loading.

It is also a poor choice where precise ductile behavior under overload is required, such as in primary structural frames.

In environments with abrasive contact or where frequent mechanical modification is expected, metals often provide more predictable performance and repairability.

How to Choose the Right GRP Product for Your Application

Selecting the correct GRP product is a specification exercise, not a branding decision.

Performance depends on how closely the material grade and form match the actual service conditions. A structured evaluation reduces the risk of premature failure, compliance issues, or unnecessary cost escalation.

Key Specifications to Check Before Buying

- Load requirements: Confirm both static and dynamic loads, including safety margins over the full service life.

- Material grade and reinforcement structure: Ensure the selected grade aligns with mechanical and electrical demands.

- Environmental exposure: Account for moisture, chemicals, UV exposure, and temperature range.

- Fire and electrical compliance: Verify suitability for building codes or electrical safety requirements where applicable.

- Dimensional tolerances and thickness: Check stability requirements to avoid deformation under sustained load.

- Quality documentation: Require test reports, batch consistency, and traceability from the supplier.

Common Buyer Mistakes and Misuse Cases

- Selecting by appearance or price alone: Visual similarity does not indicate equivalent performance or durability.

- Ignoring long-term loading effects: Underestimating creep and fatigue leads to gradual deformation and failure.

- Using electrical grades in structural roles: Insulation-focused products may lack sufficient mechanical strength.

- Over-specifying without justification: Choosing higher grades than necessary increases cost without improving outcomes.

- Assuming interchangeability with metals: GRP requires different design assumptions and support strategies.

Final Verdict — Is Glass Reinforced Polyester the Right Material?

Glass reinforced polyester is the right material when durability, corrosion resistance, electrical insulation, and weight efficiency are primary requirements.

It performs best in controlled load environments where long service life and low maintenance are valued.

GRP is not a universal substitute for metal or advanced composites, and its limitations must be acknowledged at the design stage.

When the material grade, manufacturing method, and operating conditions are properly aligned, GRP delivers reliable, predictable performance.

When misapplied, it fails gradually and expensively.

The decision should be based on service conditions, not material familiarity.

Key Takeaways

- Glass reinforced polyester is a composite system whose performance depends on correct grade selection, not appearance.

- GRP offers strong corrosion resistance, electrical insulation, and weight efficiency in non-extreme load environments.

- Manufacturing quality and fiber orientation directly influence strength and long-term reliability.

- Standards and testing protect buyers by ensuring consistency and predictable performance over time.

- GRP is not interchangeable with metals or high-performance composites without design adjustments.

- Misuse typically leads to gradual failure rather than immediate breakdown, increasing lifecycle cost.

FAQs

Is glass reinforced polyester the same as fiberglass?

Not, exactly. Fiberglass refers to the glass fibers used as reinforcement.

Glass reinforced polyester is the finished composite material where those fibers are bonded within a polyester resin matrix.

GRP implies defined material properties and controlled performance, while fiberglass is an informal term.

Is GRP toxic or hazardous?

GRP is not hazardous in normal use or installed applications.

Health considerations are limited to manufacturing or cutting activities, where dust control and basic protective measures are required.

The cured material is considered stable and safe.

How long does glass reinforced polyester last?

Service life depends on grade selection, load conditions, and environmental exposure.

In well-specified applications, GRP can perform reliably for several decades with minimal maintenance, particularly in corrosive or moisture-prone environments.

is GRP stronger than steel?

No. Steel is stronger in absolute strength and stiffness. GRP offers a higher strength-to-weight ratio and better corrosion resistance, but it does not replace steel in heavy or high-load structural applications.

Which is better, GRP or FRP?

Neither is inherently better. GRP is a specific type of FRP that uses polyester resin with glass fibers. FRP is a broader category that includes other resin systems such as epoxy or vinyl ester. The better choice depends on performance requirements, environment, cost, and compliance, not the label.