DTF on Polyester: Does It Really Work? Complete Heat, Adhesion & Durability Guide

DTF on polyester works reliably when you control heat, pressure, and dye behavior the way polyester demands.

The success rate depends less on the transfer itself and more on how you run the press: platen accuracy, dwell control, seam management, and wash care handoff.

This guide gives you the operational settings and failure prevention steps you can standardize in production.

Quick Answer Can You Use DTF on Polyester Successfully?

Yes, DTF on polyester is commercially viable for tees, hoodies, sportswear, and many blends if you press at the right temperature band and manage dye migration.

Use it when you need:

- Multi-color graphics on polyester garments without weeding.

- Consistent hand-feel across mixed garment inventories.

- A scalable workflow with repeatable press settings.

Avoid it when:

- The garment has heat reactive coatings or ultra-thin fabric that warps under pressure.

- The fabric is prone to heavy dye bleed and you can’t run blocker materials.

Why DTF Works Differently on Polyester than Cotton

Cotton tolerates heat and pressure with a wide margin. Polyester doesn’t. Your “cotton settings” may produce good adhesion but still damage the garment or cause seam distortion.

Polyester’s Heat Sensitivity vs DTF Adhesion Needs

Direct to film printing depends on adhesive powder activation and controlled melt flow into the fabric surface.

Polyester challenges that because:

- It can shine (scorch gloss) before it visibly burns.

- It can warp or distort under high platen temperature.

- It can show seam puckering after cooling due to differential shrink behavior.

Operational truth: Your goal is not maximum heat your goal is minimum heat that fully activates adhesive.

Why DTF Is Safer Than Sublimation or HTV on Polyester

- Sublimation requires high temperature and works best on light colored polyester. It also forces you into a specific garment color strategy.

- HTV can work well, but thick films and aggressive pressing often create inconsistent results on textured or performance fabrics.

DTF on polyester can be safer because you can:

- Run lower press temperature with adjusted dwell

- Maintain detail without cutting/weeding

- Use specialty low bleed materials for performance fabric printing

Best Polyester Fabrics for DTF Printing (What Actually Works)

Not all polyester behaves the same under a heat press transfer on polyester. Build a fabric approval list based on fabric weight, knit structure, and dye behavior.

100% Polyester

Best candidates:

- Medium weight interlock knits

- Fleece backed polyester (with proper seam strategy)

- Smooth jersey with stable knit

Watch outs:

- Ultra-thin jerseys can telegraph platen texture and distort

- Heavily dyed blacks/navy can trigger dye migration under heat

Polyester Blends (Cotton, Spandex, Elastane)

Blends often press easier than pure poly, but they add new variables:

- Cotton/poly blends reduce dye bleed risk vs pure poly

- Spandex/elastane increases stretch but can cause edge stress if the print area sits over high stretch zones

Production rule: For stretch blends, prioritize elasticity-compatible films and avoid oversized solid blocks.

Performance & Sportswear Polyester

This is where most shops lose time.

Performance fabrics may include:

- Moisture-wicking finishes

- DWR/coatings

- Sublimated base patterns

- Lightweight, high-stretch knits

If you run DTF on polyester for sportswear, standardize:

- Lower temperature + slightly longer dwell

- A migration-control pathway (materials + test)

- Seam avoidance and reduced pressure at edges

DTF Heat Press Settings for Polyester (Critical Section)

Your press settings must match platen reality, not the number on the display. Calibrate platen temp before you lock an SOP.

Ideal Temperature Range (Avoiding Scorching & Warping)

Practical working range for most polyester garments:

- 135 – 150°C (275 – 302°F) depending on fabric sensitivity and adhesive system

Use these rules:

- If you see shine, reduce temperature first don’t reduce pressure first.

- If adhesion fails, increase dwell time before increasing temperature.

Hard threshold: If the garment shows gloss or warp, you’re already outside safe process control for that fabric.

Pressure & Dwell Time Explained

Start points that scale well:

- Pressure: medium (firm contact without crushing knit)

- Dwell: 10 – 15 seconds for the main press

Then add:

- Post press: 5 – 10 seconds with a cover sheet to improve surface bonding and reduce edge lift risk

Operator checklist:

- Keep the film flat no bridging over seams

- Use a protective sheet to reduce shine risk

- Maintain consistent garment positioning to avoid partial contact

Why Overheating Causes “Puckered Seams” on Polyester

Seams pucker when heat and pressure lock in uneven tension:

- Fabric panels shrink/relax at different rates

- Thread reacts differently than fabric

- High pressure over seam ridges creates localized compression

Prevent it by process design:

- Never press directly over bulky seams when you can reposition

- Use a pressing pillow or pad to isolate seam height

- Lower temperature and extend dwell rather than “hammering” with high pressure

Does DTF Damage or Shrink Polyester?

DTF on polyester doesn’t inherently destroy fabric, but poor process control does. Damage usually comes from excess heat + excess pressure + seam/topstitch contact.

Shrinkage vs Warping (What Actually Happens)

Polyester typically doesn’t “shrink” like cotton in a simple way during pressing. More often you see:

- Knit distortion (warping)

- Shine (surface gloss)

- Panel tension changes that show as ripples or waviness

If the garment looks fine hot but deforms after cooling, your press cycle pushed the material past its stable range.

How Sewing Thread Causes Wavy Seams After Pressing

Thread and fabric don’t always react equally to heat:

- Thread may tighten or relax differently than adjacent fabric

- Topstitch lines become visible stress rails after cooling

Mitigation steps:

- Avoid printing zones that cross heavy topstitch lines

- Reduce pressure near seams

- Use a pad to keep seams from receiving full platen force

Wash Durability How Long Does DTF Last on Polyester?

With correct bonding and care, direct to film printing can deliver strong print durability on polyester garments. Most early failures happen because shops ship too fast or clients wash too aggressively.

First Wash Rules (Most Failures Happen Here)

Operational rule:

- Wait at least 24 hours before first wash when possible

Shop handoff rule:

- Include care instructions on the invoice/packing slip

- Tell clients not to test wash immediately after delivery

Washing Temperature, Detergents & Dryer Risk

Recommended care for wash resistance:

- Wash inside out

- Cold to 30°C

- Mild detergent

- Avoid bleach and aggressive stain removers on the print area

Drying:

- Air dry when possible

- If tumble drying, keep it low heat and avoid long cycles

Steam Cycles: Why Modern Dryers Ruin DTF Prints

Steam cycles add heat plus humidity plus time exactly the conditions that can:

- Soften adhesive

- Stress edges

- Accelerate cracking on large solid areas

Business level guidance: Warn clients explicitly to avoid steam refresh cycles if they want the print to hold up.

Common DTF Problems on Polyester (And How to Fix Them)

Treat these as production diagnostics. Don’t “try random changes.” Adjust one variable at a time and document the outcome.

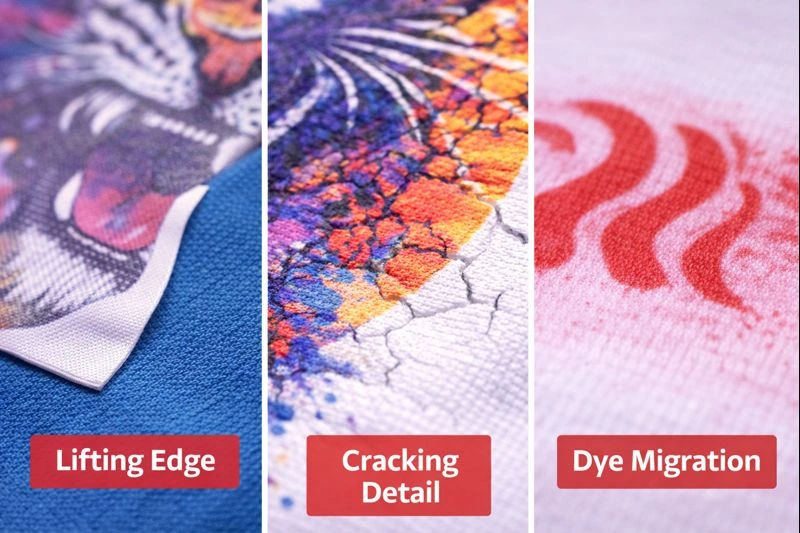

Peeling or Lifting Edges

Likely causes:

- Insufficient adhesive activation (too low temp / too short dwell)

- Platen pressure inconsistency at edges

- Post-press skipped

- Texture/finishes preventing bonding

Fix sequence:

- Add a post-press (same temp, 5–10 sec) with a cover sheet

- Increase dwell by 2–3 seconds before raising temperature

- Confirm true platen temperature with a surface thermometer

- Reduce seam interference and ensure flat contact

Cracking After Washing

Likely causes:

- Over pressing (film becomes brittle)

- Large solid fills without adequate stretch compatibility

- High heat drying and steam cycles

Fix sequence:

- Reduce main press temperature slightly and use longer dwell

- Use a film/ink system designed for stretch

- Recommend low heat drying and no steam cycles

Dye Migration & Color Bleeding

This is a polyester dye behavior issue, not a “bad transfer” issue.

Triggers:

- High press temperature

- Long dwell

- Dark reactive dyes (common in performance wear and sublimated fabrics)

Controls:

- Lower temperature and compensate with dwell

- Use low-bleed/migration-blocking materials when required

- Run a test patch on each new garment line before full production

DTF vs HTV vs Sublimation on Polyester (Real Comparison)

Use the method that fits the job, not the trend.

- DTF on polyester

- Best for: multi-color logos, detailed graphics, mixed garment inventory

- Risks: dye migration on dark performance fabrics, seam distortion if pressed poorly

- HTV

- Best for: simple shapes, names/numbers, fast personalization

- Risks: thickness/hand-feel, edge lift on textured knits, more labor for weeding

- Sublimation

- Best for: light-colored polyester where you want zero film feel

- Limits: color constraints (needs light base), high heat, not viable on cotton-heavy blends

When You Should NOT Use DTF on Polyester

Don’t run DTF on polyester when the garment’s material science fights your process:

- Coated or treated polyester (certain water-repellent or slick finishes)

- Ultra lightweight performance fabrics that warp under platen pressure

- Heavily dyed or sublimated garments with high migration risk when you can’t use blockers

- Designs that must remain ultra-breathable (large solid chest panels can feel sealed)

If you must proceed anyway, price it as a controlled-risk job and test first.

Final Verdict: Is DTF the Best Choice for Polyester Printing?

DTF on polyester is a strong default for production shops that need consistency across varied polyester garments especially when you standardize a low-temperature workflow and manage dye behavior.

It won’t replace sublimation for “no-feel” prints on light poly, and it won’t beat HTV for quick single-color personalization.

But for scalable, detailed prints on mixed polyester inventory, it performs well when you treat press control as a process not a guess.

Key Takeaways (Read Before You Press)

- Use the lowest temperature that fully activates adhesive powder.

- Calibrate platen temperature; don’t trust the display number.

- Increase dwell before increasing heat when adhesion underperforms.

- Avoid seams and bulky stitch zones; use pads/pillows when needed.

- Plan for dye migration on dark performance fabrics and test before production.

- Protect durability with clear wash-care instructions and no steam cycles.

FAQs

Can DTF be used on 100% polyester?

Yes. DTF on polyester works on 100% poly when you keep temperature controlled, maintain flat contact, and validate dye behavior on dark colors. Use lower press temperature bands and tune dwell for full bonding.

Will DTF crack on polyester after washing?

It can, usually due to over-pressing, incompatible stretch demands, or high-heat drying habits. Reduce heat, avoid brittle over-curing, and instruct clients to skip steam dryer cycles to protect print durability.

What temperature is safe for polyester DTF printing?

Most shops succeed in the 135–150°C (275–302°F) range, adjusted by fabric sensitivity. Start lower, increase dwell for adhesion, and only raise temperature if you confirm the garment can tolerate it without shine or distortion.

How long does DTF last on polyester?

DTF on polyester can last for dozens of washes when it’s pressed correctly and cared for properly (cold wash, inside-out, low heat or air-dry). High-heat drying and steam cycles reduce durability fastest.

Is DTF or vinyl better for polyester?

DTF is better for polyester when you need full-color, detailed artwork and fast production without weeding, but it requires tighter control of heat and dye migration on performance fabrics.

Vinyl (HTV) is better when you want simple logos, names, and numbers with a predictable process and easy reprints especially on sports jerseys though it adds labor and can feel thicker.

What fabric works best for DTF?

The best fabric for direct to film printing is smooth, stable, medium-weight cotton or cotton-poly blends because they press flat and bond consistently.

For polyester garments, medium weight, tightly knit polyester works best, while ultra- light performance fabrics and coated materials require extra testing due to heat sensitivity and dye migration.