Nylon vs Polyester Rope: Which Is Stronger, Safer, and Better for Real-World Use?

Choosing nylon vs polyester rope is a safety and performance decision, not a preference.

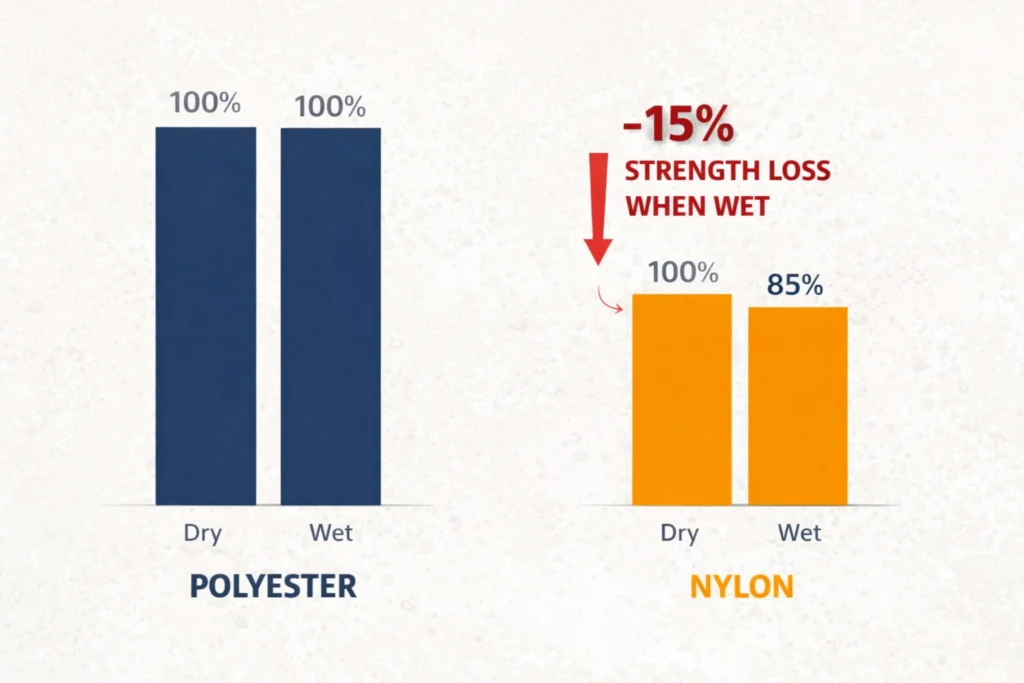

Nylon can lose 10–15% strength when wet, and its high stretch stores energy that can recoil if the line fails under tension.

Polyester stays more stable in water and performs better under long UV exposure.

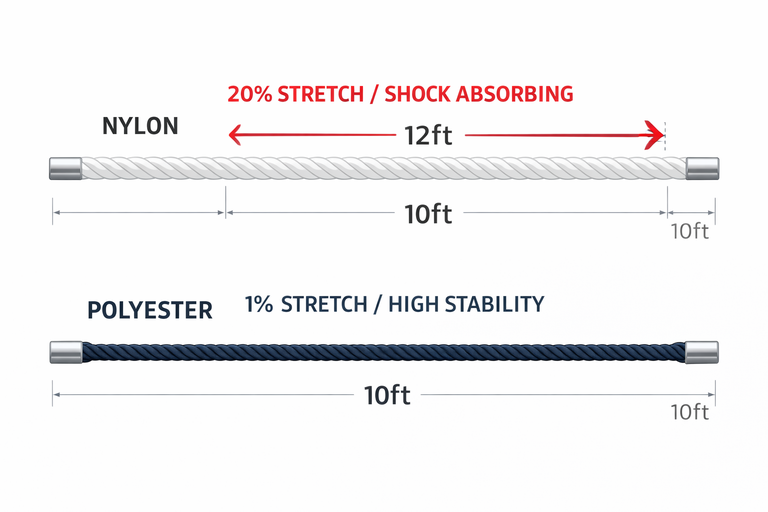

Nylon typically stretches 20–30%, while polyester is closer to 8–12%, which changes control, load stability, and injury risk.

This guide gives a clear recommendation by application, including lifecycle value for outdoor and marine rope use.

Quick Verdict: Nylon vs Polyester Rope at a Glance

| Decision Factor | Nylon Rope | Polyester Rope |

| Strength under load | High tensile behavior, but drops when soaked | Stable load-bearing line behavior, wet or dry |

| Stretch level | 20–30% stretch (shock-absorbing rope) | 8–12% stretch (low-stretch rope) |

| Water performance | Absorbs water; can lose 10–15% strength when wet | Unaffected by water; consistent handling |

| UV resistance | Breaks down faster in long sun exposure | Better UV stability for outdoor use |

| Life cycle outdoors | More frequent replacement in UV + wet cycles | Lasts longer outdoors, fewer replacements |

| Best use cases | Towing, recovery, dynamic loading | Marine rope, rigging, long-term tension |

When Nylon Rope Is the Better Choice

- Choose nylon when the line must stretch under load, so peak force drops and anchors see smoother loading

- Use nylon for shock-absorbing rope recovery pulls, so jerks convert into controlled energy absorption.

- Select nylon for temporary load-bearing line setups, so flexible handling supports short-duration use without long-hold creep (permanent stretching) focus.

When Polyester Rope Makes More Sense

- Choose polyester when low-stretch rope control is required, so load position stays stable and predictable.

- Use polyester for marine rope work, so wet exposure doesn’t reduce performance or increase water uptake.

- Select polyester for UV-exposed outdoor runs, so fiber breakdown slows and replacement cycles reduce.

- Prefer polyester for long-term load-bearing line use, so tension and length stay consistent over extended holds

Strength & Load Behavior (How These Ropes Actually Perform)

Nylon often tests higher in raw strength, but real-world strength shifts under moisture and sustained tension.

It behaves like a shock-absorbing rope, which buffers hardware from sudden force spikes. That protection matters when waves, jerks, or winch starts would otherwise overload anchors and cleats.

Polyester holds a more consistent load profile because it stays stable in length and resists creep (permanent elongation over time).

This matters for fixed rigging, because the line stays tight without constant adjustment. It behaves like a low-stretch rope, so load position remains predictable under steady tension.

Break strength is not the safe number for decision-making.

Most users should focus on Working Load Limit (WLL), which is typically only 15–25% of tensile strength. This prevents overloading based on lab numbers and reduces failure risk under real handling conditions.

| Performance Factor | Nylon Rope | Polyester Rope |

| Tensile behavior | High initial strength, but changes more with wet and sustained holding | Stable load-bearing line behavior across wet and dry use |

| Shock load response | Strong shock-absorbing rope buffer that reduces force spikes | Limited damping, transfers force faster under impact |

| Elastic recovery | High recovery, but higher long-term creep under constant tension | Better length stability with consistent recovery |

| Snap-back risk | Higher risk under heavy tension due to stored stretch energy | Lower risk because stretch energy is limited |

Tensile Strength vs Shock Load Absorption

Static loads are steady pulls where tension builds gradually, like holding a dock line or a fixed rigging point.

Dynamic loads are sudden forces, like towing starts, winch shock, or wave impact on a marine rope.

Nylon performs better in dynamic loading because it acts as a buffer, reducing force spikes that can rip out cleats.

Tensile strength alone is misleading because safe use depends on WLL, not break numbers. Most ropes should be worked at 15–25% of rated tensile strength, and knots can reduce strength further.

Never judge safety by tensile rating alone when snap-back can occur.

Stretch Characteristics and Snap-Back Risk

Nylon stretch improves safety in controlled dynamic use, but recoil risk rises when tension is high and failure happens suddenly.

Polyester stretch is limited, so energy storage is lower and the load-bearing line behaves more predictably in long holds.

Snap-back risk becomes more severe in confined zones like a small boat deck or a tight driveway.

- Snap-back injury when stored energy releases under high tension

- Loss of load control when stretch shifts positioning during critical holds

- Hidden overload buildup because the line “feels” softer while energy accumulates

Water, UV, and Weather Resistance

Environmental exposure decides rope life faster than load rating.

For nylon vs polyester rope selection, focus on water uptake, drying behavior, salt crystal abrasion, and UV strength retention.

Choose based on whether the rope will sit wet, bake in direct sun, or cycle through repeated marine rope exposure.

Nylon Rope in Wet Conditions

Expect nylon to absorb water, increasing weight and changing handling control. Large nylon ropes can gain over 50% weight when fully saturated, which increases strain during deployment and recovery.

Wet nylon also loses effective strength and becomes less consistent under load, especially across soak-dry cycles. Drying can take long enough that performance stays unstable if the rope is stored damp or repeatedly re-wetted.

Verdict: Avoid nylon for continuous wet exposure; use it only when shock absorption is required and drying is controlled.

Pro Tip: If you use nylon for marine applications, rinse it with fresh water after salt exposure. This flushes out the abrasive salt crystals you identified, significantly extending the rope’s lifespan.

Polyester Rope Under Sun and Salt Exposure

Choose polyester for sun, salt spray, and long outdoor exposure because UV degradation is slower. Data commonly cited in UV chamber comparisons shows polyester can retain 80%+ tensile strength after extended UV exposure, while untreated nylon can lose 30–40% over similar exposure windows.

Salt exposure matters even when ropes do not rot, because drying salt leaves crystals that scrape fibers during flexing.

Nylon’s higher water uptake can allow deeper salt retention, increasing internal abrasion over time.

Polyester’s hydrophobic behavior reduces salt embedding and helps maintain shape retention for marine rope use.

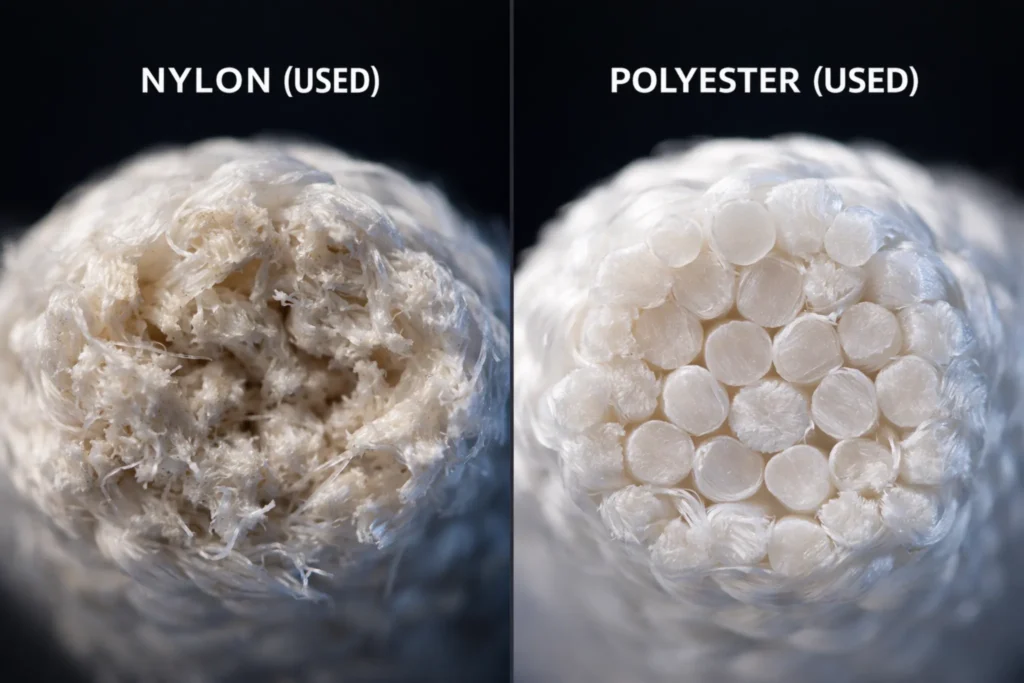

Durability, Abrasion, and Long-Term Wear

Durability drives ownership cost more than initial purchase.

Nylon vs polyester rope selection should account for abrasion zones, repeated bending, and long-duration tension. A rope that keeps surface integrity reduces downtime and prevents early replacement.

Nylon handles abrasion, but its higher stretch can create internal wear through fiber-to-fiber friction during repeated loading. That internal friction accelerates fuzzing and pilling, which reduces grip control and makes wear harder to assess during inspection.

Polyester holds shape and maintains surface integrity longer because low-stretch rope behavior reduces internal friction. It keeps its “hand” in the grip longer, staying smoother and more consistent after abrasion cycles.

For marine rope and rigging, this helps the load-bearing line stay predictable over long service life.

| Wear Factor | Nylon Rope | Polyester Rope |

| Abrasion resistance | Good, but internal wear increases under repeated stretch cycles | Strong long-term abrasion stability outdoors |

| Fiber memory | More creep and shape change under sustained tension | Better dimensional stability and shape retention |

| Replacement frequency | Higher in wet + UV exposure and dynamic cycling | Lower in sun, salt, and long-duration steady use |

“Modern coatings can improve the surface life of both fibers, the underlying characteristics of the core material stretch vs. stability—remain the primary drivers of wear.”

Safety Considerations Most People Ignore

Most rope failures are predictable if you evaluate energy storage, recoil path, and heat buildup.

Nylon vs polyester rope selection should include how the line behaves when overloaded, cut, or released under tension.

Safety depends on clearance, handling control, and system friction, not just strength.

Stretch, Recoil, and Injury Risk

Snap-back zone is the line of fire where stored energy travels if the rope parts or a fitting fails. With high-stretch nylon, that snap-back zone can extend the entire length of the rope, not just the middle section.

Nylon stores more energy under load, so it requires more safety clearance around the load-bearing line and anchor points.

- Snap-back injury risk increases when nylon is heavily tensioned

- Line-of-fire exposure increases when operators stand anywhere along the rope path

- Hidden overload risk increases because stretch masks rising load conditions

Heat, Friction, and Load Failure Scenarios

Friction heating builds when a rope runs fast over a winch, cleat, pulley, or tight bend during repeated tension cycles.

Nylon melts near 210°C (410°F), while polyester holds closer to 255°C (491°F), which is why polyester is safer in high-friction handling. This heat gap becomes critical in hoists, winches, and fast pulls.

- Winch burn risk during high-speed tensioning or long pulls

- Pulley heat buildup when rope bends tightly under load

- Knot failure risk because knots create friction points where internal heat concentrates first.

Best Rope by Application (Decision Section)

| Application | Choose Nylon When… | Choose Polyester When… | Primary Decision |

| Marine / dock lines | You need shock-absorbing rope behavior for surge loads and short-term tie-ups | You need marine rope stability, low stretch, and reliable wet performance | Choose polyester for most docks; choose nylon only for impact-heavy mooring. |

| Towing / recovery | You expect sudden jerks and want stretch to reduce peak force | You need controlled pulling, stable length, and less recoil risk | Choose nylon for recovery pulls; choose polyester for steady towing and rigging. |

| Camping / utility | You need a flexible line that can absorb movement and tie easily | You need a low-stretch rope that holds tension for tarps and long hangs | Choose polyester for setup stability; choose nylon only when movement is expected. |

Marine & Dock Lines

Choose polyester for dock lines that stay wet, sit in sun, or hold steady tension.

Nylon fits only when waves or surge create repeated shock loads and extra clearance is available for recoil risk.

“For 2026, most recreational boaters are switching to polyester dock lines because they don’t stiffen and shrink like nylon after a season in salt water, making them easier to handle long-term.”

Towing, Recovery, and Rigging

Choose nylon when recovery involves jerks, starts, or sudden load spikes and you need energy absorption.

Choose polyester for rigging and steady pulls where control, predictable load position, and lower snap-back risk matter.

Climbing, Camping, and Utility Use

Choose polyester for utility use where tension must stay locked, especially for tarps, lines, and fixed hanging loads.

Choose nylon only when movement is unavoidable and shock absorption protects the load path.

Most real-world decisions follow one pattern: choose nylon for dynamic loading where stretch protects hardware, and choose polyester for long-term outdoor or marine rope use where low-stretch control and consistent performance reduce safety and replacement risk.

Cost vs Performance — Is Nylon Worth the Extra Stretch?

Upfront Cost vs Replacement Cycles

Upfront price matters less than how fast performance drops in your environment.

Nylon can cost more and still require earlier replacement if it stays wet, sees UV, or holds constant tension.

In high-UV, high-salt exposure, an untreated nylon line may need replacement up to twice as often as a high-quality polyester line to maintain the same safety margin.

Nylon also carries a hidden loss in wet use because it can lose 10–15% strength when wet, meaning you are effectively paying for strength you cannot always use if the rope is constantly submerged.

Polyester typically holds performance outdoors longer, reducing downtime risk from degraded load-bearing line behavior.

When Paying More Actually Saves Money

Pay more for nylon only when shock-absorbing rope behavior prevents hardware damage or force spikes that cause failure.

Pay more for polyester when long-term outdoor exposure, marine rope duty, and stable tension are required to avoid frequent replacements.

Avoid saving upfront when failure downtime or snap-back risk carries real cost.

Storage & Care (Pro-Level Rope Life Extension)

Rope failure often starts in storage, not in use.

Nylon vs polyester rope selection only pays off if you control salt residue, drying time, and abrasion during storage. Treat storage as a safety step, not a convenience step.

Nylon Storage After Salt Exposure

Rinse nylon in fresh water after salt exposure so crystals do not remain inside the fibers. Salt crystals can act as internal abrasives during flexing, accelerating wear and fuzzing.

Dry nylon fully before storage to reduce strength loss and prevent inconsistent handling on the next use.

Polyester Storage for Outdoor Use

Store polyester clean and dry to preserve surface integrity and “hand” in the grip.

Polyester is less affected by water, but grit and salt on the surface still increase abrasion during handling. Avoid tight bends during storage to maintain shape retention and consistent load-bearing line behavior.

Checklist for Inspection (3-Step Tactile Guide)

Use this inspection before any high-tension load, towing, or marine rope setup.

Nylon vs polyester rope safety depends on early detection of abrasion, heat glazing, and internal wear that may not show in a quick glance.

- Visual: Look for fuzzing, pilling, or glazing (a shiny or slightly melted look) to identify abrasion and heat damage.

- Touch: Feel for crunchy, stiff, or flat spots that indicate internal salt abrasion or friction heating near knots and bends.

- Measure: Check for thinning; if one section is noticeably smaller in diameter, internal fibers may be failing and the line is no longer safe.

Decision: Retire any rope that shows glazing, stiff core spots, or localized thinning before it enters a snap-back zone under load.

Final Recommendation — Which Rope Should YOU Choose?

Choose polyester for most nylon vs polyester rope decisions because it delivers low-stretch control, stable wet strength, and better UV resistance for real outdoor use.

Choose nylon only when you need shock-absorbing rope behavior for dynamic loads and you can maintain extra safety clearance for recoil.

Avoid guessing based on break strength alone.

Decision Summary Table by Use Case

- Choose polyester for marine rope, dock lines, rigging, and long-term outdoor setups.

- Choose nylon for towing, recovery pulls, and any load path with repeated shock loading

- Avoid nylon for constant wet storage or long-duration static tension where creep and instability increase.

Review your Working Load Limit (WLL) for your specific application before buying to ensure safety margins are met.

Key Takeaways (Read This before Buying)

- Choose polyester when you need a low-stretch rope that holds tension, position, and length under steady load.

- Choose nylon when shock loads are expected and stretch must reduce peak force on anchors and hardware.

- Avoid nylon for continuous wet exposure because performance drops and drying time increases.

- Prefer polyester for marine rope and UV-exposed outdoor runs to reduce early wear and replacement cycles.

- Treat snap-back risk as a primary decision factor whenever the load-bearing line will be highly tensioned.

FAQs

Is nylon or polyester stronger for outdoor use?

Polyester is generally stronger for long-term outdoor use because it is unaffected by water and has superior UV resistance.

While nylon may test slightly stronger when dry, it loses 10-15% of its strength when wet and degrades faster in sunlight, making its long-term performance weaker outdoors.

Which rope lasts longer in the sun?

Polyester rope lasts significantly longer in the sun. Data shows polyester can retain over 80% of its tensile strength after extended UV exposure, while untreated nylon can lose 30–40% in the same timeframe. This makes polyester the better choice for marine and permanent outdoor rigging.

Which rope has more stretch: nylon or polyester?

Nylon has significantly more stretch, typically 20–30% at breaking strength, which is why it’s called a shock-absorbing rope.

Polyester is a low-stretch rope, stretching only about 8–12%, which makes it more stable for holding position under steady tension.

Which rope is better for marine use and dock lines?

Polyester is generally better for most marine uses because it resists rot, doesn’t absorb water (so it stays lightweight and strong), and holds its shape better.

Nylon is only recommended when extreme shock absorption is needed for heavy surge mooring, and proper safety clearance for potential snap-back is available.

Can I use nylon rope for towing a vehicle?

Yes, you can use nylon rope for dynamic recovery pulls (e.g., getting a stuck vehicle out of mud) because its high stretch absorbs the shock of the jerk.

However, you must prioritize safety by staying out of the “line of fire” or “snap-back zone,” as stored energy in the nylon can cause severe injury if the line or an anchor point fails.