Nylon 11: Properties, Uses, Price, and How It Compares to Nylon 12

Quick Answer — What Is Nylon 11 and Why Is It Used?

Nylon 11 (Polyamide 11) is a 100% bio-based engineering plastic derived from renewable castor oil, specifically designed for high-vibration and chemically aggressive environments. Engineers specify PA11 over petroleum-based alternatives because it offers superior impact resistance, fatigue life, and UV stability.

While PA12 is often the default for 3D printing, Nylon 11 is the preferred choice for functional components like living hinges and fuel lines that require maximum ductility and a lower carbon footprint.

- Property Profile: 100% bio-based with exceptionally high elongation at break.

- Best For: High-impact automotive parts, offshore oil/gas umbilicals, and functional 3D prototypes.

- Key Distinction: Higher ductility and better low-temperature toughness than Nylon 12.

Nylon 11 Chemical Formula & Molecular Structure

Chemical Formula Explained

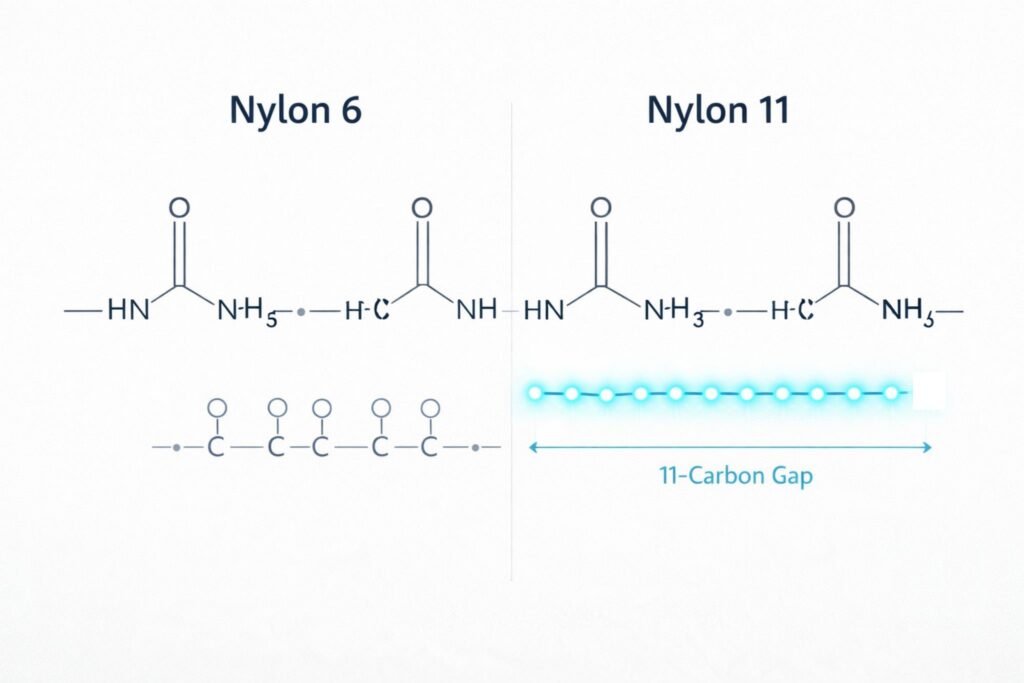

Nylon 11 (PA11) is defined by its repeating-unit formula (C11H21NO)n.

The “11” signifies the 11-carbon aliphatic segment within the monomer backbone, synthesized from castor-oil intermediates.

This extended hydrocarbon chain increases the distance between adjacent amide groups compared to Nylon 6 or 6/6.

This specific molecular geometry gives PA11 a “hydrocarbon-like” profile, resulting in exceptional hydrophobic properties and chemical inertness.

Nylon 11 Molecular Structure and Chain Behavior

PA11’s molecular architecture features a low amide group concentration, which limits the availability of hydrogen-bonding sites for water molecules.Practical Outcome: Nylon 11 absorbs significantly less moisture than standard polyamides, maintaining high dimensional stability even in saturated environments.

The increased chain mobility afforded by the long 11-carbon sequence allows the polymer to dissipate energy more effectively.

This molecular behavior supports superior elongation at break and prevents brittle failure in sub-zero temperatures. Specify PA11 for components where moisture-induced swelling or dielectric loss would compromise the assembly’s performance.

Key Properties of Nylon 11 (Why Engineers Choose It)

Mechanical Properties (Strength, Flexibility, Impact)

- Elongation at Break: Typically 200–350%.

Selection Criteria: Specify PA11 for components requiring significant deformation without fracture, such as living hinges or snap-fits.

- Impact Resistance: Maintains high Charpy Impact Strength in sub-zero conditions.

Selection Criteria: Use for outdoor equipment or aerospace parts exposed to cold-start mechanical loads.

- Tensile Strength: 45–55 MPa (unfilled).

Note: Reinforcing with glass or carbon fiber increases stiffness but creates a trade-off in ductility.

- Fatigue Life: Exceptional resistance to cyclic stress.

Selection Criteria: Prefer PA11 for dynamic tubing and vibration-dampening clips.

Thermal Properties & Heat Resistance

Nylon 11 has a melting point of 182–190°C. For design purposes, prioritize Continuous Use Temperature (CUT) over peak melting points; PA11 performs reliably between 80°C and 125°C depending on mechanical load.

Because the Glass Transition Temperature (Tg) sits at 40–50°C, expect a reduction in stiffness as the material enters warm operating environments.

Pro Tip: Switch to heat-stabilized or reinforced grades if the application faces prolonged thermal aging or high-load creep.

Moisture Absorption & Dimensional Stability

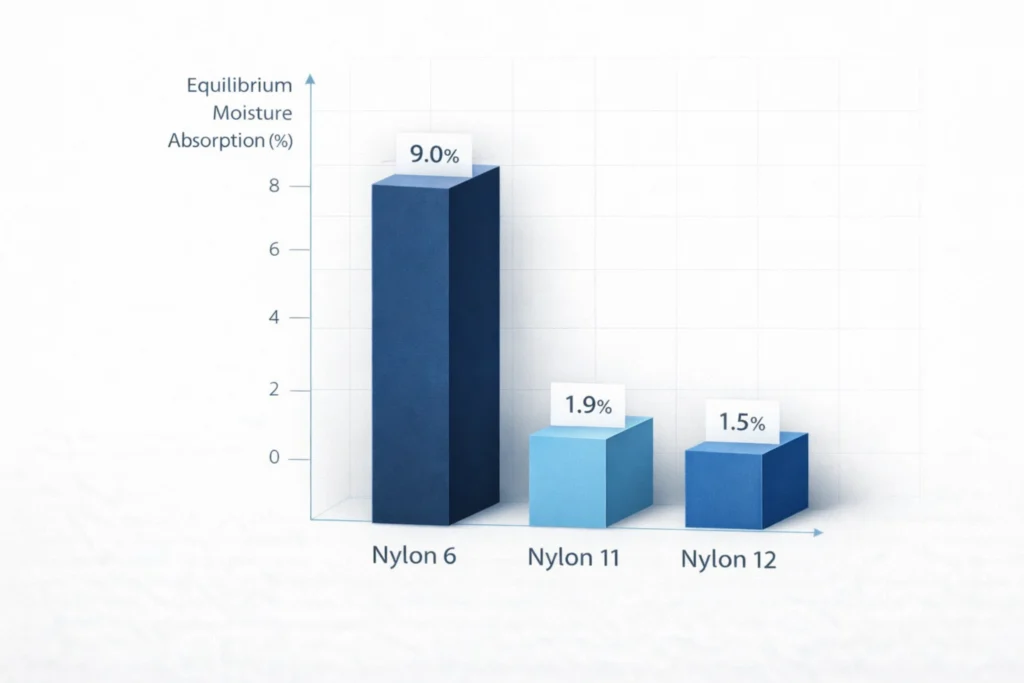

PA11’s low amide density significantly limits its hygroscopic behavior. With a saturation moisture uptake of only ~1.9% (compared to ~9% for Nylon 6), it minimizes “hydro-expansion.

Practical Result: Parts maintain tight tolerances, press-fit integrity, and stable dielectric properties in humid or submerged environments. Use PA11 to prevent the swelling that leads to mechanical binding or fluid leaks in high-precision assemblies.

Chemical & Environmental Resistance

- High Resistance (Specify for): Aliphatic hydrocarbons, gasoline, diesel, lubricants, road salts, and seawater. PA11 is the industry standard for under-the-hood automotive fluids.

- Weathering: Naturally stable against UV degradation; however, specify black-pigmented or UV-stabilized grades for 20+ year outdoor service life.

- Incompatibility Risks: Avoid exposure to strong mineral acids, oxidizing agents, or prolonged high-temperature steam. While PA11 resists moisture, hot-water hydrolysis can eventually degrade the polymer chain in pressurized steam applications.

Common Uses of Nylon 11 in Industry

Automotive & Fuel Line Applications

Automotive engineers specify PA11 for fuel and vapor management due to its low fuel permeation rates and hydrocarbon resistance. This ensures compliance with stringent evaporative emission standards over the vehicle’s lifecycle.

In high-vibration routing zones, PA11’s fatigue resistance prevents crack initiation at clips and quick-connect interfaces.

- Key Applications: Fuel lines, vent lines, and underbody protective jacketing.

- Operational Advantage: PA11 maintains ductility in sub-zero environments and resists degradation from road salts and zinc chloride (common in de-icing agents).

Electrical, Tubing & Industrial Components

In electrical infrastructure, utilize PA11 for cable sheathing where abrasion resistance and environmental stress-crack resistance (ESCR) are mandatory.

- Oil & Gas: Specify PA11 for offshore “umbilicals” and riser-adjacent tubing. Its ability to withstand cyclic bending in seawater while remaining chemically inert to hydrocarbons prevents catastrophic failure in dynamic subsea environments.

- Pneumatics: Use PA11 tubing for precision fluid conveyance. Its low hygroscopy ensures that moisture-driven swelling does not cause fitting leaks or pressure drops, unlike more moisture-sensitive polyamides.

Nylon 11 in 3D Printing (SLS & MJF Context)

Specify Nylon 11 for functional parts requiring high elongation at break and impact toughness. In Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), PA11 provides superior ductility compared to PA12, making it the industry standard for living hinges, snap-fits, and high-strain latches.

- Design Guidance: Prioritize PA11 for compliant mechanisms and parts requiring elastic deformation without brittle fracture.

- 2026 Context: PA11 exhibits better near-isotropic properties in the Z-axis than PA12, improving the reliability of thin-walled industrial parts.

- Selection Logic: Choose PA11 when mechanical survival under impact is critical; default to PA12 only when dimensional accuracy and lower material costs are the primary constraints.

Nylon 11 Price — Why It Costs More

Raw Material & Production Factors

Nylon 11 pricing is structurally higher than petroleum-based polyamides due to its feedstock dependency on castor oil.

Unlike high-volume petrochemical streams, castor cultivation is geographically concentrated, making yield and subsequently monomer cost vulnerable to weather volatility and acreage shifts.

Furthermore, PA11 requires a specialized monomer synthesis path (11-aminoundecanoic acid) that lacks the massive economies of scale found in Nylon 6 or Nylon 12 production.

Market Concentration: Arkema remains the dominant global producer of PA11 (marketed as Rilsan). This limited competitive landscape, combined with high-barrier synthesis, maintains PA11’s position as a premium engineering polymer.

Cost vs Lifecycle Performance

Evaluate Nylon 11 based on Total Cost of Ownership (TCO) rather than initial resin cost per kilogram. The typical 20–30% price premium over PA12 is an investment in risk mitigation.

- Reduced Failure Rates: PA11’s superior ductility eliminates crack-related warranty claims in high-vibration or sub-zero environments.

- Maintenance Efficiency: In offshore or automotive routing, extended fatigue life reduces unplanned downtime and replacement labor costs that far exceed the material price gap.

- Operational Logic: Specify PA11 when failure consequences are high, qualification cycles are expensive, or where the “Cost of Failure” (COF) exceeds the marginal material savings of a lower-grade polymer.

Nylon 11 vs Nylon 12 — Which Should You Choose?

Performance Comparison (Flexibility, Moisture, Heat)

- Select Nylon 11 (PA11) for applications governed by cyclic loading, impact, or elastic deformation. PA11 offers superior elongation at break and maintains its toughness in sub-zero environments, making it the standard for living hinges and high-vibration automotive clips.

- Select Nylon 12 (PA12) when stiffness and dimensional precision are the primary requirements. PA12 exhibits slightly lower moisture absorption and higher crystal density, resulting in more predictable shrinkage and tighter tolerances in thin-walled designs.

- Thermal Performance: Both materials share similar melting points (175°C–190°C). However, evaluate based on Creep Resistance and Continuous Use Temperature (CUT); PA11 typically performs better under dynamic thermal stress, while PA12 is more stable under static loads.

Cost, Availability & Application Fit

Procurement and design engineers must balance material cost vs. failure risk.

- PA12 Availability: PA12 benefits from a diversified global supply chain and multiple resin producers (Evonik, EMS-GRIVORY, UBE), leading to stable pricing and high availability across SLS/MJF and injection molding formats.

- PA11 Performance Premium: PA11 carries a 20–30% cost premium and is primarily single-sourced (Arkema). Specify PA11 only when the application’s fatigue life or chemical durability justifies the cost such as in offshore umbilicals or fuel management systems where a single brittle failure could result in catastrophic system loss.

Decision Table — Nylon 11 or Nylon 12?

| Feature | Nylon 11 (PA11) | Nylon 12 (PA12) | Engineering Choice |

| Ductility | Higher (up to 350%+) | Lower (stiffer) | PA11 for hinges |

| Hygroscopy | Low (stable) | Lowest (max stability) | PA12 for tight fits |

| Cold Impact | Excellent (-40°C) | Good (can be brittle) | PA11 for outdoors |

| Supply Chain | Concentrated (Higher $) | Diversified (Competitive $) | PA12 for cost-control |

| Sustainability | 100% Bio-based | Petroleum-based | PA11 for ESG |

Sustainability & Recycling of Nylon 11

Bio-Based Origin & Carbon Footprint

Nylon 11 is synthesized from castor beans, a renewable feedstock that thrives on marginal land unsuitable for food crops. From a 2026 ESG perspective, this origin allows manufacturers to decouple material procurement from fossil-based carbon volatility.

- Carbon Logic: PA11 effectively “sequesters” biogenic carbon during the plant’s growth phase, significantly lowering the cradle-to-gate carbon footprint compared to PA12 or PA6.

- Selection Criterion: Utilize PA11 to reduce Scope 3 intensity in high-performance assemblies where mechanical requirements prohibit the use of lower-spec, consumer-recycled plastics.

Recyclability & ESG Considerations

Nylon 11 is technically recyclable, but its environmental ROI depends heavily on the manufacturing process and material purity.

- Additive Manufacturing (SLS/MJF): Sustainability is governed by the powder refresh rate. PA11 typically allows for high reuse ratios; however, engineers must balance refresh percentages against the degradation of mechanical properties (specifically ductility) over multiple heating cycles.

- Mechanical Recycling: For injection-molded or extruded parts, prioritize closed-loop recycling within the manufacturing facility to prevent cross-contamination.

- Regulatory Audit: When reporting ESG gains, verify material origins through ISCC+ (International Sustainability and Carbon Certification) or Mass Balance accounting. Avoid generic “recyclable” claims; instead, track and report specific regrind percentages and yield loss to provide audit-ready data for corporate sustainability disclosures.

When Nylon 11 Is the Wrong Choice

Performance Limits & Cost Constraints

- Thermal Ceilings: Avoid specifying PA11 for duty cycles exceeding 125°C continuous use. At these temperatures, the material is prone to accelerated creep, significant stiffness loss, and long-term thermo-oxidative degradation.

If your application requires higher thermal thresholds, consider PPA (Polyphthalamide) or glass-reinforced Nylon 6/6.

- Chemical Incompatibility: Do not utilize PA11 in environments containing strong mineral acids (e.g., sulfuric or hydrochloric), strong bases, or high-concentration oxidizing agents. These chemistries attack the amide linkages, leading to rapid molecular chain scission and part failure.

- Budgetary Constraints: PA11’s 20–30% price premium is rarely justifiable for high-volume, low-criticality consumer goods. If the “cost of failure” is low and the environment is benign, default to Nylon 6 or Nylon 12 to maintain project margins.

- Supply Chain Resilience: Treat PA11 with caution for programs requiring geographically diverse multi-sourcing. Because production is highly concentrated (primarily through Arkema), PA11 is more susceptible to single-source disruptions than the diversified Nylon 12 or Nylon 6 supply chains.

Selection Logic: Specify PA12 when the priority is procurement flexibility and dimensional precision; reserve PA11 for applications where impact toughness and bio-based ESG targets are non-negotiable.

Final Verdict — Is Nylon 11 Worth Using?

Nylon 11 is the technically superior choice when reliability is the primary metric and the cost of part failure measured in downtime, safety risk, or warranty claims—exceeds the material’s price premium.

Specify PA11 for components that must endure high-frequency vibration, low-temperature impact, and aggressive hydrocarbon exposure without moisture-driven dimensional shifts.

Conversely, reject PA11 for low-criticality consumer applications where project margins are thin, or for environments exceeding its 125°C thermal threshold.

As of 2026, Nylon 11 stands as the premier bio-based polyamide for high-ductility engineering; it justifies its cost only when service life and toughness are non-negotiable performance requirements.

Key Takeaways (Read Before Selecting Nylon 11)

- Ductility & Impact: Specify PA11 when failure risk is governed by impact or cyclic fatigue. It is the industry standard for snap-fits, living hinges, and high-vibration tubing.

- Dimensional Stability: Expect ~1.9% moisture saturation; utilize this low hygroscopy to avoid the significant swelling (~9%) and property shifts typical of Nylon 6.

- Thermal Constraints: Adhere to a 125°C continuous use ceiling unless the grade is heat-stabilized or glass-reinforced for specific high-heat validation.

- Chemical Defense: Prioritize PA11 for systems exposed to hydrocarbons, oils, road salts, and UV radiation (specify stabilized grades for outdoor longevity).

- Commercial Logic: Justify the 20–30% price premium through lifecycle ROI; lower warranty claims and extended service life offset the initial resin cost.

- Selection Priority: Default to Nylon 12 for static, stiffness-driven applications or standard 3D printing; reserve Nylon 11 for mission-critical toughness and ESG compliance.

FAQs

Is Nylon 11 (PA11) truly a sustainable plastic?

Yes. Nylon 11 is 100% bio-based, derived entirely from renewable castor oil. It allows manufacturers to reduce Scope 3 emissions and decouple production from petroleum supply chains. Unlike many “bio-plastics,” it remains fully functional in high-stress industrial environments.

Why is Nylon 11 better than Nylon 12 for 3D printing?

Nylon 11 is superior for functional, high-impact parts. While Nylon 12 is stiffer and easier to source, Nylon 11 provides significantly higher elongation at break and Z-axis isotropy, making it the standard for living hinges, snap-fits, and crash-test prototypes.

What is the melting point of Nylon 11?

The melting point of Nylon 11 is typically between 182°C and 190°C (360°F–374°F). However, engineers should design for a Continuous Use Temperature (CUT) of 125°C or lower to prevent creep and mechanical property degradation under sustained thermal load.

Does Nylon 11 absorb water like Nylon 6?

No. Nylon 11 is highly hydrophobic with a saturation moisture absorption rate of approximately 1.9%. This is significantly lower than Nylon 6 (~9%), resulting in superior dimensional stability and consistent mechanical performance in high-humidity or submerged applications.

Why is Nylon 11 more expensive than other polyamides?

The 20–30% price premium is driven by its concentrated castor oil supply chain and complex monomer synthesis. Because production is primarily controlled by specialized manufacturers like Arkema, it is positioned as a high-performance, low-volume “specialty” polymer.

Is Nylon 11 food-safe or biocompatible?

Many Nylon 11 grades are USP Class VI and ISO 10993 compliant, making them suitable for medical devices and certain food-contact applications. Always verify the specific ISCC+ certification and grade-level documentation from the resin supplier before specifying for regulated industries.