Nylon Injection Molding: Process Control, Material Selection, and Real-World Production Limits

Nylon injection molding is a controlled exercise in three linked realities:

- Physics: Managing shear thinning flow, gate freeze-off, and crystallization.

- Chemistry: Navigating hygroscopic equilibrium and property shifts relative to Tg.

- Business Limits: Maintaining Cp/Cpk stability against resin lot variability and ambient humidity.

The only reliable way to run nylon at scale is to treat moisture content as a primary process variable.

In 2026, sustainability (bio-attributed resins) and closed-loop smart sensors are no longer “nice-to-have” they are the baseline for stabilizing scrap rates and preventing dimensional drift.

Quick Verdict — Is Nylon Injection Molding the Right Choice?

When Nylon Injection Molding Makes Sense

Choose nylon when the part must survive mechanical load, vibration, and temperature cycling while retaining toughness and wear performance. It’s a proven path for metal-to-plastic conversion in brackets, housings, gears, and under-hood components, especially when you need chemical resistance to oils, fuels, greases, and automotive fluids.

- High stress + impact loading where commodity plastics creep or crack

- Metal replacement targets: weight reduction, consolidation, corrosion resistance

- Chemical resistance requirements (oils, hydrocarbons, salts, many solvents)

- Reinforced options (e.g., GF PA) enabling stiffness and creep control at temperature

When Nylon Injection Molding Creates Problems

Avoid nylon when your success metric is tight dimensional precision across uncontrolled humidity exposure. Because PA is hygroscopic, it will move toward hygroscopic equilibrium after molding; that moisture uptake changes dimensions and mechanical properties, and it can undermine “inspection-at-press” assumptions.

Nylon fails most often at dimensional stability in humid environments and at long-term durability when the process allows hydrolytic degradation (from wet resin at temperature). It also becomes cost-inefficient when you need extreme tolerances without funding sensors, conditioning protocols, and closed-loop control.

How Nylon Behaves During the Injection Molding Process

Melt Flow, Shrinkage, and Crystallinity

Nylon is semi-crystalline; therefore, rheology and crystallization kinetics drive every molding outcome.

In the barrel and runner, PA exhibits shear thinning: viscosity drops as the shear rate rises. While this helps fill thin-walled sections, it increases the process sensitivity to velocity profiling and gate design.

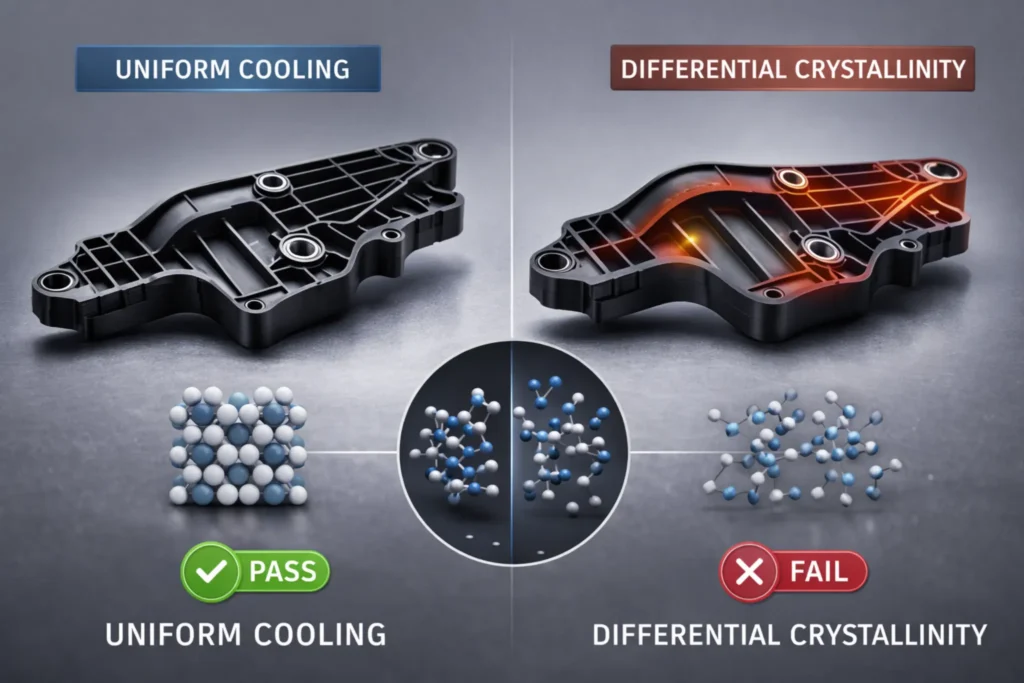

Cooling rate is the hidden control knob. Fast cooling suppresses crystal growth, while slow cooling allows more uniform morphology. This directly impacts the mechanical properties:

- High Crystallinity: Higher Strength + Higher Shrinkage + Higher Chemical Resistance

- Low Crystallinity: Better Ductility + Lower Shrinkage + Higher Creep Risk

- Uneven Cooling: Differential Crystallinity + Dimensional Drift = High Scrap Rates

Practically, identical machine settings can produce non-conforming parts if cooling uniformity shifts, as the crystallinity distribution changes the shrink field after gate freeze-off.

Moisture Sensitivity and Drying Requirements

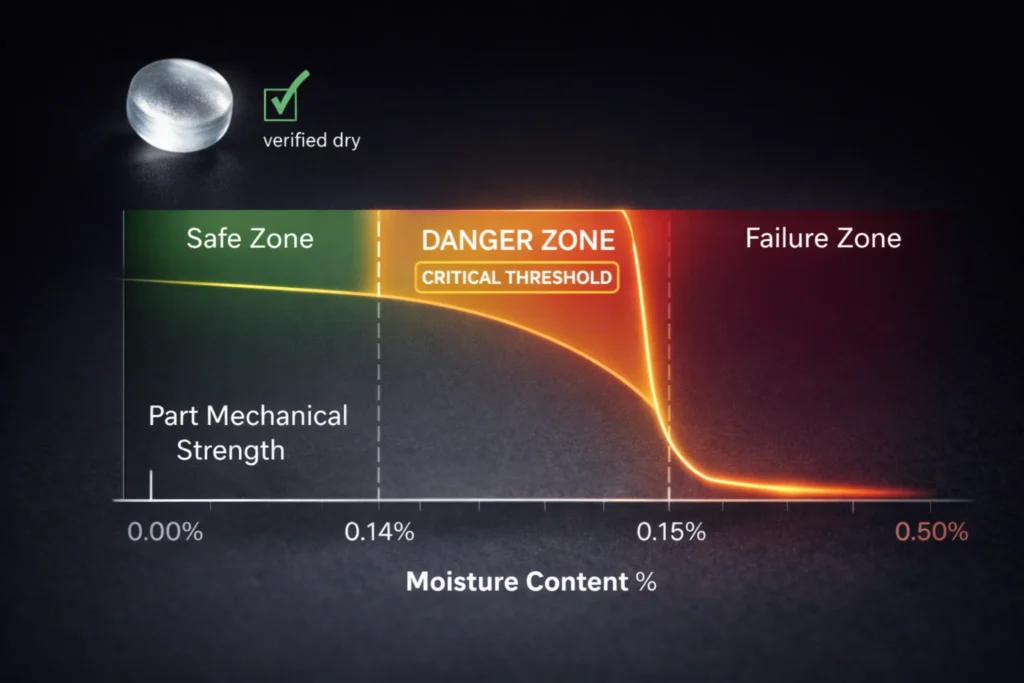

PA is hygroscopic; it chases equilibrium with ambient humidity. In 2026, production-grade nylon molding assumes verified drying via desiccant dryers or vacuum dryers to maintain a stable start and prevent viscosity drift.

Moisture Thresholds (Verified by Weight):

- Target at press for most PA: 0.15% – 0.20%

- High-strength/Critical PA66: < 0.12% (Hard limit to prevent hydrolytic degradation)

- Above Threshold Risks: Splay, internal voiding, and brittleness driven by molecular weight loss during the melt phase.

Selecting the Right Nylon Grade for Injection Molding

Nylon 6 vs Nylon 6/6 (Strength, Heat, Moisture Trade-offs)

The PA6 vs PA66 decision is a molecular architecture trade.

PA6 (caprolactam-based) delivers superior flow and surface replication.

PA66 (diamine-adipic acid based) features tighter chain packing, supporting higher crystallinity and thermal stability.

| Grade | Heat Deflection (0.45 MPa) | Impact Strength | Relative Shrinkage |

| PA6 | ~160°C – 180°C | High (Ductile) | 0.7% – 1.5% |

| PA66 | ~200°C – 230°C | Moderate | 0.8% – 2.0% |

| PA6 GF30 | ~200°C+ | Reduced | 0.4% – 0.6% |

| PA66 GF30 | ~250°C+ | Low (Stiff) | 0.3% – 0.5% |

Design Reality: Stabilizer packages and fiber sizing drive lot-to-lot behavior more than the base polymer alone.

Treat equivalency claims with skepticism unless validated through mechanical testing.

Glass-Filled Nylon (Stiffness vs Warpage Risk)

Glass-filled PA hits stiffness targets but introduces anisotropic shrinkage. Fibers align with the flow, causing the part to shrink differently along the flow versus across it. This alignment creates high modulus but increases warpage sensitivity.

Critical Risk: Fibers do not cross weld lines. Therefore, the weld-line strength is only as strong as the base resin, regardless of glass percentage.

For tight tolerances, rely on Moldflow analysis for fiber orientation—never on “operator feel.”

Impact-Modified and Lubricated Grades

When toughness dominates, specify impact-modified grades to prevent brittle failure at low temperatures.

For gears and bushings, use MoS₂-filled or PTFE-filled PA to reduce friction.

Note: these lubricants can shift the processing window and reduce creep resistance; always re-validate the pack/hold window.

Traditional vs Sustainable Nylon Grades (Bio-Based & Recycled)

In 2026, sustainable nylon selection follows mechanical requirements first, then sourcing models.

- Bio-based (PA11/PA1010): Derived from castor oil, these offer credible performance with a lower carbon footprint.

- Mass Balance: Use mass balance certification to claim bio-attributed content without changing processing parameters.

- Recycled Grades: Lock down allowable viscosity variation in your QC thresholds to prevent “green” variability from becoming production scrap.

Critical Processing Parameters for Nylon Injection Molding

Barrel Temperature, Mold Temperature, and Residence Time

Stable molding for Polyamide (PA) requires controlling melt temperature while strictly limiting thermal history.

Nylon tolerates heat, but it fails under the combination of heat + time + moisture. This leads to molecular weight loss, often misdiagnosed as a cosmetic issue.

2026 Baseline Starting Ranges:

- PA6 Profile: 240–270°C (Rear-to-front gradient)

- PA66 Profile: 260–295°C

- Nozzle: +5–15°C above front zone.

Pro-Tip: Use reverse-taper nozzles to prevent “drooling” caused by low melt viscosity.

- Mold Temp (Unfilled): 60–90°C (Balances surface finish and crystallinity)

- Mold Temp (Glass-Filled): 80–110°C (Stabilizes shrinkage and reduces frozen-in stress)

- Maximum Residence Time: Keep under 5–8 minutes.

The Residence Time Trap: If the shot size is less than 20% of barrel capacity, the material sits hot for too long, causing drifting viscosity and brittleness. Corrective action is process architecture (smaller barrel), not a temperature adjustment.

Injection Pressure, Pack/Hold Strategy, and Sink Control

- High Effective Pressure: Nylon requires significant packing to compensate for shrinkage in thick sections. Under-packing results in internal voids and weight drift.

- Data-Driven Hold Time: Set hold time by a gate freeze study, not by habit.

Step-by-Step Pack/Hold Validation:

- Establish Fill Profile: Avoid erratic shear spikes that alter viscosity.

- Conduct Part-Weight Study: Increment hold time until part weight plateaus; this marks gate freeze-off.

- Optimize Hold Time: Set hold time slightly above the plateau to absorb process variation.

- Tune Pressure: Adjust hold pressure to eliminate sinks without inducing flash.

Critical Note: For glass-filled nylon, packing changes fiber alignment near the gate. If a sink fix causes warpage, you need a geometry change (gate relocation or wall thinning) rather than more pressure.

Integrate cavity pressure sensors for closed-loop stability in high-volume 2026 production lines.

Advanced Troubleshooting in Nylon Injection Molding

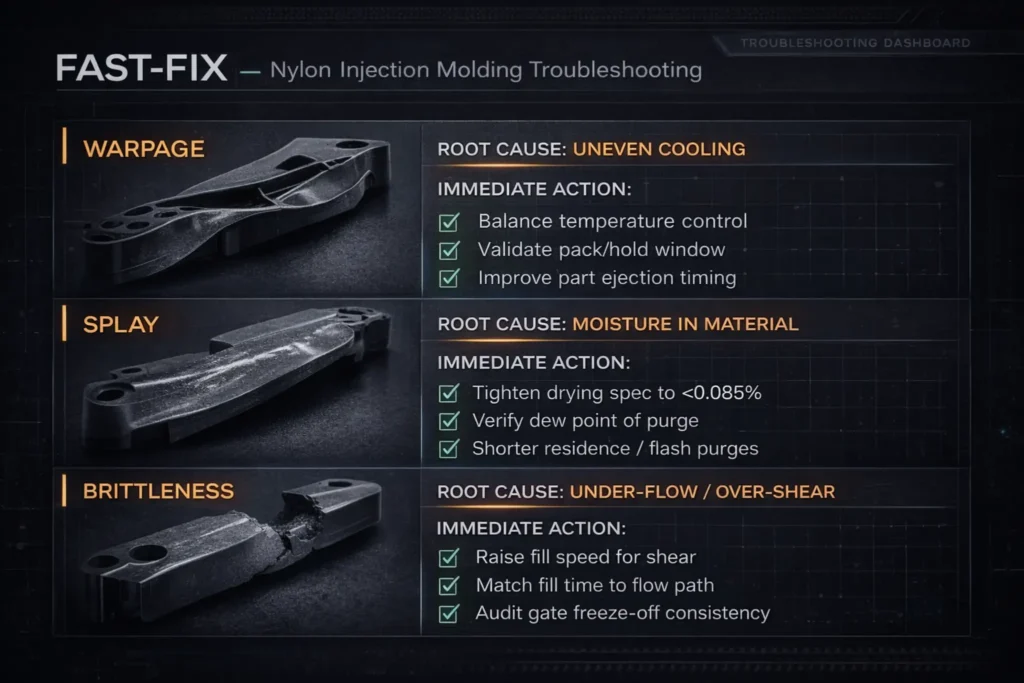

Warpage, Voids, and Dimensional Drift

| Defect | Immediate Adjustment | Long-term Tooling / System Fix |

| Warpage (GF PA) | Reduce shear spikes; verify moisture; stabilize mold temp. | Redesign gate to control fiber orientation; optimize cooling hot spots. |

| Voids / Porosity | Increase hold pressure; verify weight plateau at gate freeze. | Relocate gate to feed thick sections; redesign thick-to-thin transitions. |

| Dimensional Drift (Humidity) | Standardize conditioning; verify dryer dew point. | Design for moisture expansion; switch to PA12 for lower uptake. |

Splay, Burn Marks, and Brittleness

| Defect | Immediate Adjustment | Long-term Tooling / System Fix |

| Splay (Silver) | Verify resin dryness; lower injection speed. | Upgrade to vacuum drying; implement sealed conveying. |

| Burn Marks | Reduce end-of-fill velocity; switch over earlier. | Add vents at weld-line convergence; use vacuum venting. |

| Brittleness | Check for hydrolytic degradation; reduce residence time. | Right-size barrel (20–80% shot); enforce purge discipline. |

Root-Cause Hierarchy (Nylon-Specific):

- Splay: Usually moisture-driven (hygroscopic resin flashing) amplified by venting limits.

- Burn Marks: Trapped gas + compression heating, not “overheated plastic.”

- Brittleness: Polymer damage (time/temperature/moisture) masquerading as design failure.

AI-Driven Process Monitoring and Defect Prevention

A 2026 “smart factory” nylon cell treats the press as a controlled system. The workflow utilizes cavity pressure sensors and In-mold IR sensors to capture a “pressure fingerprint” of a perfect part.

During production, the machine compares live traces to this reference. If the system detects a slower pressure rise (indicating a viscosity shift) or a shortened holding window, a machine learning loop classifies the cause—such as a dryer dew point drift or a resin lot change. The controller then applies real-time, bounded corrections to the velocity profile or pack pressure. This prevents defects at the signature level, ensuring that scrap is eliminated before the mold even opens.

Tooling & Mold Design Considerations for Nylon

Gate Design, Venting, and Flow Length Limits

Nylon fills aggressively because it shear-thins, then it shrinks hard during crystallization. Tooling must support both: controlled filling and rapid evacuation of trapped air.

Gate Design Rules:

- Holding Window: Size the gate to preserve a usable holding window. Keep the gate land length short (half the gate diameter) to prevent premature freeze-off.

- Anisotropic Control: For glass-filled PA, place gates to control fiber orientation, which drives warpage.

Venting: This is where nylon programs quietly fail. Use larger and more frequent vents than teams expect—especially near knit lines.

- Critical Threshold: Target vent depths of 0.012 mm to 0.025 mm. This allows gas evacuation without causing flash in nylon’s low-viscosity melt. If you see burns, assume venting capacity issues before adjusting melt temperature.

Mold Steel, Surface Finish, and Wear Considerations

While unfilled nylon is forgiving, glass-filled grades are highly abrasive.

- Steel Selection: Specify hardened H13 or D2 for gates, runners, and core pins.

- Erosion Points: Expect fiber-driven erosion at the gate and high-shear corners.

- Maintenance: Design for easy access; vents and gates must be cleanable during production without requiring tool teardown.

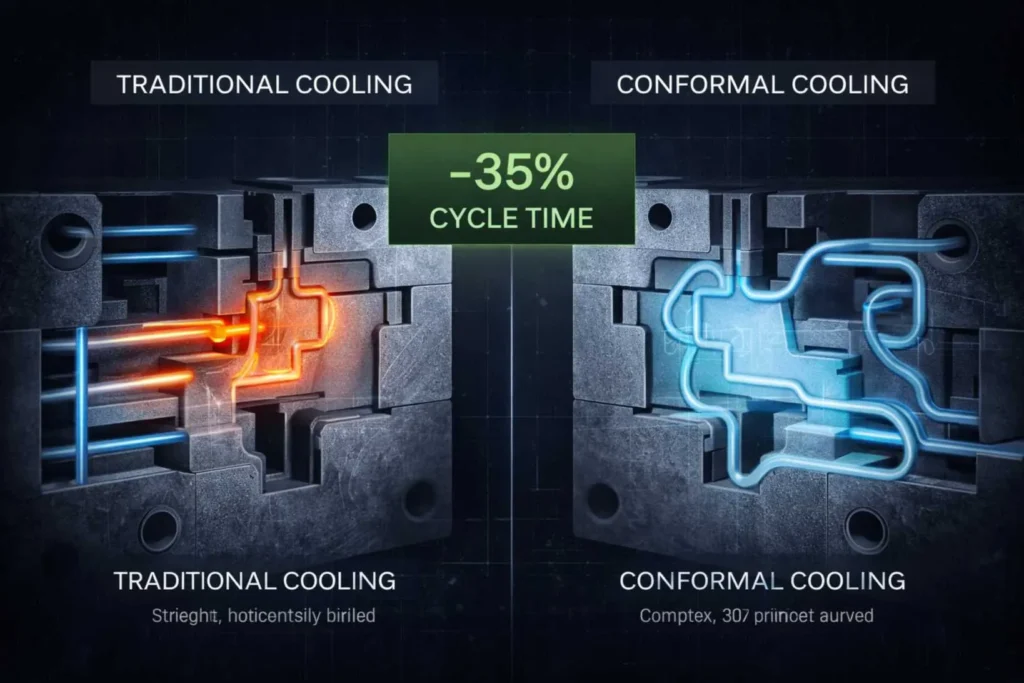

Conformal Cooling & 3D Printed Inserts for Nylon Molding

Cooling uniformity is the ceiling on part stability. Conformal cooling—delivered via 3D-printed metal inserts—places channels where conventional drilling cannot reach, such as following the geometry of deep ribs or thick bosses.

The 2026 Production Payoff:

- Cycle Time: Typically a 20–40% reduction by eliminating hot spots.

- Quality: Higher ROI through reduced differential crystallinity, less warpage, and tighter dimensional repeatability. Conformal cooling attacks the root cause of shrinkage instability rather than masking it with machine settings.

Nylon Injection Molding vs Other Plastics

ABS vs Nylon (Heat, Strength, Moisture Stability)

- Performance: Choose Nylon (PA) for higher fatigue resistance and wear behavior in high-stress environments. Choose ABS for cosmetic appearance and simple indoor dimensional control.

- Chemistry: Choose Nylon for chemical resistance to oils, greases, and automotive fluids. Choose ABS for parts that must ignore humidity-driven dimensional changes.

- Thermal: Choose PA66 (Reinforced) for heat deflection targets exceeding 200°C. Choose ABS for applications where thermal exposure stays below 90°C.

- Organization: Choose Nylon when your plant has the process discipline for controlled drying and moisture conditioning. Choose ABS for broad manufacturability across less-specialized suppliers.

Nylon vs Acetal (POM) for Precision Parts

- Structural vs. Precision: Choose Nylon for structural stiffness and creep control at temperature. Choose POM for low friction and precision in humid environments, as POM is significantly less hygroscopic.

- Tribology & NVH: Choose POM for sliding components where repeatable fit and low wear are the primary drivers. Choose Nylon for gears requiring NVH damping, as it absorbs vibration more effectively than Acetal.

- Impact: Choose Nylon when impact toughness is required and you can tolerate the moisture-equilibrium expansion.

Bottom line: Nylon wins on the structural performance ceiling and metal replacement; ABS wins on cosmetics and easy tolerance holding; POM wins on precision and tribology when humidity variability is part of the operational duty cycle.

Cost, Yield, and Long-Term Production Economics

Material Cost vs Scrap Rate

Material cost is visible; scrap cost is multiplicative. With nylon (PA), a small increase in scrap rate can erase any resin savings because you also pay for machine time, labor, energy, and downstream disruption.

Decision Logic:

- A 5–10% resin cost reduction is rarely worth a 1–2% scrap increase in high-volume programs. Scrap is lost capacity.

- Nylon defects trace back to controllable inputs: moisture content, venting, and pack/hold control.

- Benchmark suppliers on cost per good part with verified dimensions, not just raw material price per kilo.

In practice: Spending more on a grade with tighter viscosity control can be cheaper if it reduces process drift and scrap, especially when paired with smart sensors and closed-loop control that prevent drift from becoming rejects.

Tool Life, Maintenance, and Process Stability

Tooling economics for nylon are dominated by wear, not just cycle time. Glass-filled nylon is abrasive and will attack gates, runners, and shutoffs. As wear progresses, the business pain presents as flash creep, inconsistent gate freeze-off, and rising variation.

Operational Controls that Protect Tool Life:

- Specify hardened steel (H13) for reinforced PA high-wear zones.

- Treat vent cleaning and cooling circuit health as scheduled maintenance.

- Monitor process signatures (part weight, cavity pressure). Investigate tooling condition before chasing machine settings.

- Factor the OpEx of post-molding conditioning tanks into the long-term cost per part calculation.

The Economic Objective: Extend tool life and protect Cp/Cpk by preventing gradual wear and maintenance neglect from turning into chronic scrap, while optimizing energy use per part via strategies like conformal cooling.

Final Recommendation — When to Specify Nylon Injection Molding

Decision Matrix by Application Type

| Application Type | Specify Nylon (PA) When… | Avoid Nylon When… | Best-Fit Nylon Strategy |

| Structural Mounts | Heat, vibration, and mechanical load dominate. | Tolerances must hold across uncontrolled humidity. | PA66 GF; heat stabilizers; Moldflow for fiber/warpage; cavity pressure control. |

| Electrical Connectors | Need heat resistance and creep control under load. | Moisture-driven shift risks contact geometry without conditioning. | PA66 GF; tight drying; validate gate freeze-off; AI-traceability for HV safety. |

| Wear Components | Load, wear, and fatigue performance are primary. | Precision fit must remain invariant across humidity swings. | Lubricated PA (PTFE/MoS₂); control moisture and cooling uniformity. |

| Cosmetic Housings | Structural needs are moderate; surface finish is manageable. | Flawless appearance is required across varying resin lots. | PA6 for flow; only use if cosmetics are moisture-tolerant; otherwise use ABS. |

| Precision Parts | Tolerances are specified at a defined conditioned state. | Drawing demands “as-molded” precision in humid duty. | PA12/PA11; define conditioning state; closed-loop pack control via sensors. |

Key Takeaways for Engineers & Buyers

- Moisture is a Process Variable: Never treat drying as a “storage detail.” Target < 0.15% moisture to prevent hydrolytic degradation.

- Specify the State: Define tolerances and mechanicals at a specific state (e.g., Dry-as-Molded or 50% RH Conditioned).

- Tool for the Grade: Use hardened H13 steel and conformal cooling to combat the abrasiveness of glass-filled grades and reduce cycle times by 20-40%.

- Leverage AI: In 2026, use cavity pressure sensors to prevent scrap from reaching the customer.

FAQs

Why is my nylon part brittle after molding?

Usually caused by hydrolytic degradation (molding wet resin) or excessive residence time in the barrel. Check dryer performance and shot-to-barrel ratio.

How much does nylon shrink?

Unfilled nylon shrinks 1.0–2.0%, while glass-filled grades shrink significantly less (0.3–0.6%) but exhibit anisotropic (uneven) shrinkage that leads to warpage.

Can I use recycled nylon for structural parts?

Yes, provided you use mass balance certification and lock down viscosity variation. In 2026, high-quality recycled PA66 can match virgin performance if the process is sensor-stabilized.