Delrin vs. Nylon: The Engineer’s Guide to Choosing the Right Plastic

Selecting between Delrin vs Nylon often dictates the thin margin between high-precision success and catastrophic field failure. While both engineering polymers offer durability, choosing the wrong material for high-humidity or high-impact environments leads to environmental swelling or fatigue cracks.

This guide provides the technical selection criteria required to justify your material choice during design reviews, focusing on dimensional stability, mechanical thresholds, and 2026 manufacturing realities.

The 30-Second Summary: Comparison Table & Quick Verdict

Engineers requiring immediate data for Delrin vs Nylon selection should prioritize moisture sensitivity and impact requirements.

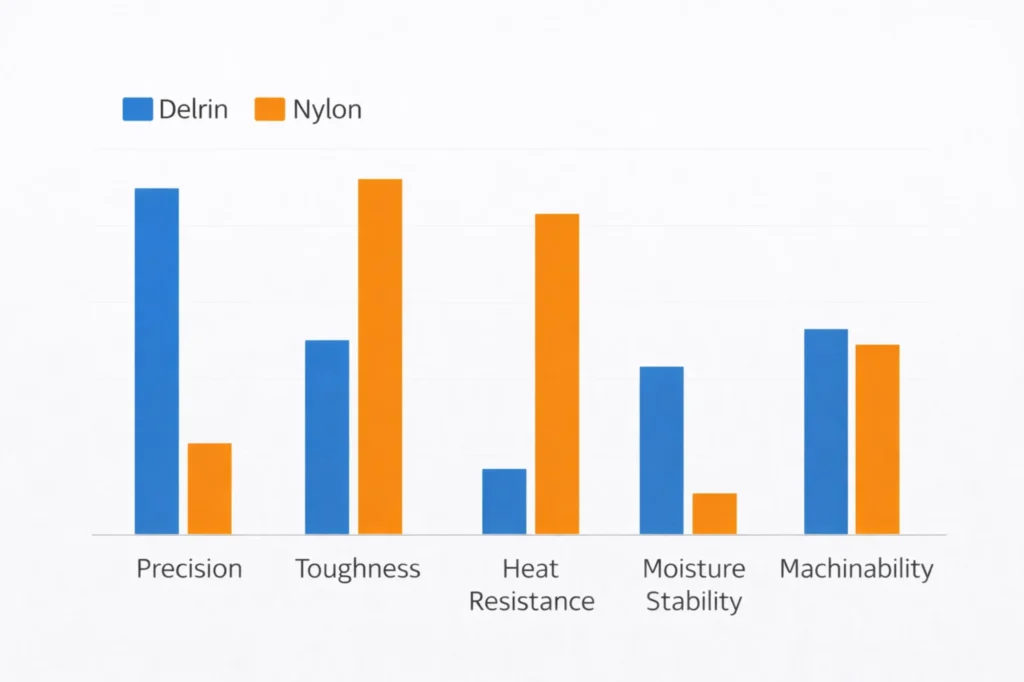

Delrin excels in precision environments, while Nylon dominates in high-load, high-heat structural roles.

Comparison Matrix: Mechanical & Thermal Properties

| Property | Delrin (Acetal) | Nylon (6/66) | Winner | Key Reason |

| Water Absorption | 0.20% | 8.00% | Delrin | Negligible swelling in humid/wet zones. |

| Tensile Strength | 10,000 psi | 12,000 psi | Nylon | Superior structural load capacity. |

| COF (Friction) | 0.2 | 0.25 | Delrin | Smoother “slip” for precision gears. |

| Max Service Temp | 180°F | 210°F – 250°F | Nylon | Better stability in high-heat engine bays. |

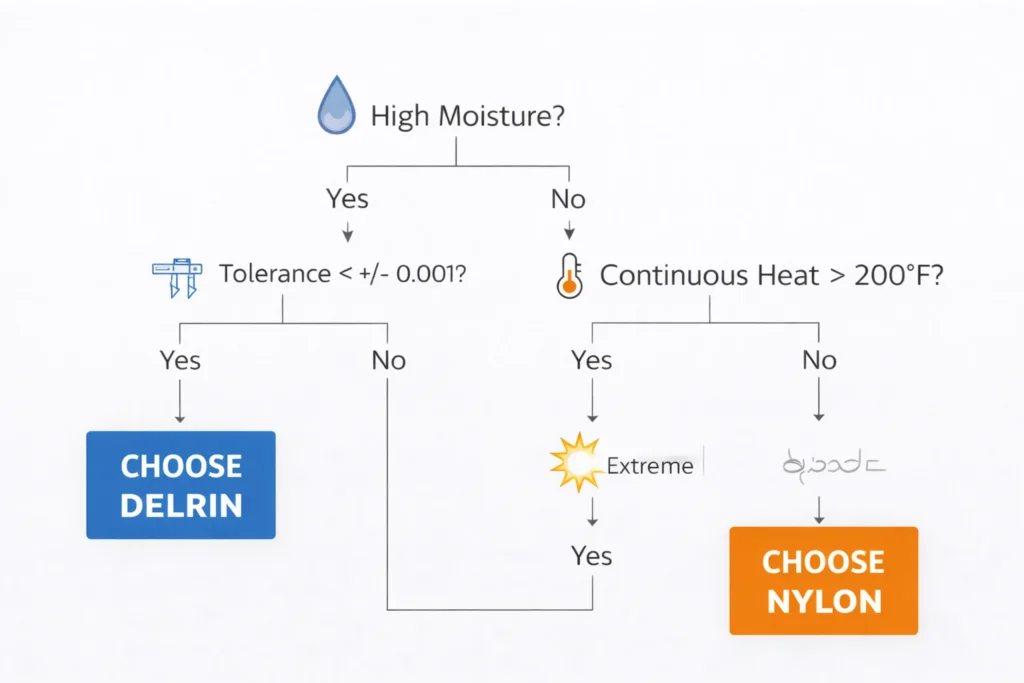

The “Rule of Thumb”: When to Pick Delrin vs. Nylon

Choose Delrin if:

Maintaining +/- 0.001” tolerances in variable humidity is critical.

Applications involve submerged marine hardware or fuel system valves.

You require high stiffness and fatigue resistance for repetitive snap-fits.

Choose Nylon if:

The part must survive heavy impact or extreme vibrational loads.

Operating temperatures consistently exceed 200°F.

You are utilizing SLS or MJF 3D printing for functional prototyping.

Material Chemistry: Why Their Origins Dictate Their Behavior

The fundamental performance gap in the Delrin vs Nylon debate stems from their molecular architecture.

One is built for rigid stability, while the other is engineered for flexible resilience.

Delrin (POM): The Crystalline “Metal-Like” Plastic

Delrin is a polyoxymethylene (POM) homopolymer characterized by a highly uniform, densely packed crystalline structure. This high crystallinity grants the material its signature “metal-like” properties: exceptional tensile strength, high stiffness, and a distinct “spring-back” memory.

When a part is deflected, the tightly organized molecules allow it to return to its original shape without permanent deformation, making it the premier choice for precision mechanical links.

Nylon (PA): The Versatile, Tough Polyamide

Nylon is a polyamide (PA) featuring a molecular chain linked by amide groups. These linkages are inherently more flexible than POM, providing Nylon with its world-class impact resistance and energy absorption.

However, these same amide groups are “hydrophilic,” meaning they actively attract water molecules. This chemical attraction causes the polymer chains to push apart as they absorb moisture, resulting in the predictable swelling and loss of rigidity that characterizes Nylon in humid environments.

Delrin (Homopolymer) vs. Generic Acetal (Copolymer): A Vital Distinction

Practitioners must distinguish between Delrin (the homopolymer) and generic Acetal (the copolymer).

Delrin offers 15% higher tensile strength, but its manufacturing process often results in centerline porosity, small gaseous voids in the center of thick slabs.

While Copolymer Acetal avoids this porosity and offers better chemical resistance to hot water/steam, it lacks the raw mechanical “bite” and fatigue endurance of genuine Delrin.

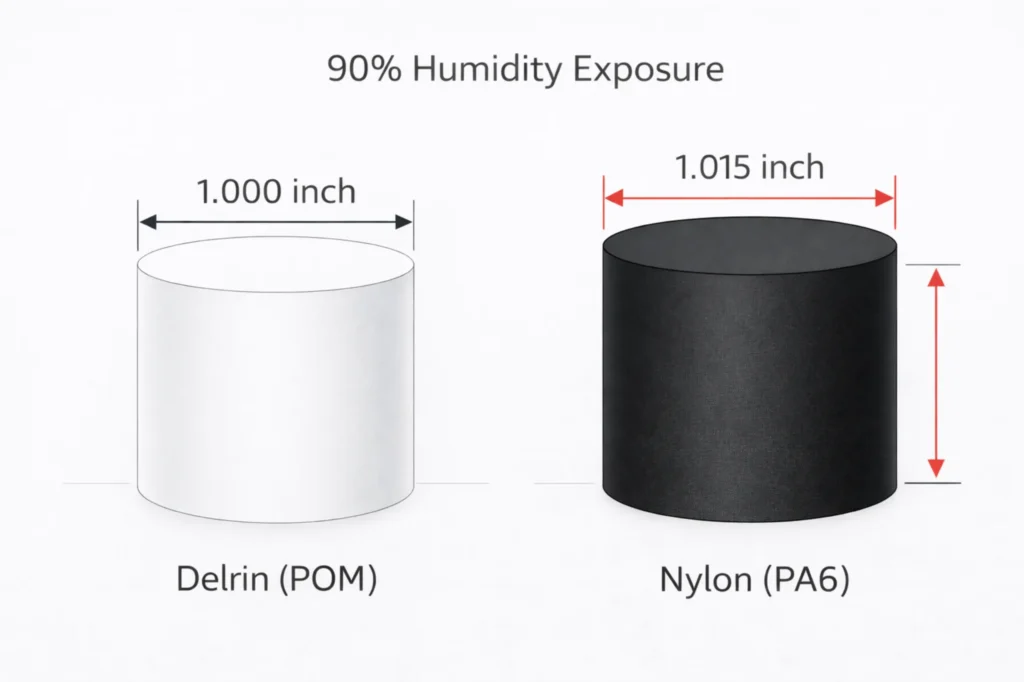

Dimensional Stability: The Battle Against Moisture

Dimensional stability remains the single most decisive factor when evaluating Delrin vs Nylon for precision assemblies. While mechanical strength is comparable, the way these polymers react to atmospheric moisture dictates their long-term reliability in the field.

Why Nylon “Grows”: Understanding Hygroscopic Absorption

Nylon is inherently hygroscopic, meaning it possesses a molecular affinity for water. At a chemical level, water molecules penetrate the polyamide chains, acting as a plasticizer. This process increases ductility but causes significant physical expansion.

By 2026 engineering standards, a standard Nylon 6/6 part exposed to high humidity can grow between 0.5% and 2.0% in total volume. This “growth” is not merely surface-level; it is a structural change that can cause shafts to seize in their housings or bolt holes to drift out of alignment.

Precision Tolerances: Why Delrin is the Gold Standard for Machined Parts

In contrast, Delrin is virtually hydrophobic. Its dense crystalline structure leaves little room for moisture infiltration, resulting in a saturated absorption rate of less than 0.2%. This stability is why machinists and engineers mandate Delrin for components requiring +/- 0.001” tolerances.

While a Nylon gear might swell and bind during a humid summer, a Delrin gear maintains its pitch and center-to-center distance regardless of seasonal shifts.

If your design cannot tolerate more than 0.002″ of thermal or hygroscopic drift, Delrin is the only viable selection.

Environmental Impact: Performance in Submerged or High-Humidity Settings

The performance delta widens in submerged or saturated environments. When Nylon reaches its saturation point, it undergoes a dramatic reduction in mechanical properties, often losing up to 50% of its initial stiffness and tensile modulus. This makes it unsuitable for marine hardware or underwater fittings.

Delrin, however, retains nearly 100% of its physical properties when submerged. For pump impellers, fuel sender units, and valve seats that must operate in fluids, Delrin’s resistance to moisture-induced degradation ensures the part remains functionally rigid throughout its service life.

Mechanical Strength & Durability Analysis

Engineers must distinguish between raw strength and functional durability. In the Delrin vs Nylon comparison, the choice hinges on whether the component must withstand a sudden blow or sustain a constant, heavy load without deforming.

Impact Resistance: Why Nylon Wins in High-Abuse Environments

Nylon is the industry benchmark for toughness. When subjected to high velocity stress measured by Izod Impact Strength, Nylon possesses a unique ability to “yield” and absorb kinetic energy. Its molecular structure allows for significant elongation before failure, meaning it deforms slightly to dissipate force rather than shattering.

For protective housings, industrial hammer heads, or automotive brackets subjected to road debris, Nylon’s superior energy absorption ensures the component remains intact under extreme physical abuse.

Stiffness and Creep: Why Delrin Holds Its Shape Under Load

If your part must remain under constant tension, Delrin is the superior choice due to its resistance to creep (the tendency of a solid material to move slowly or deform permanently under persistent mechanical stress).

Delrin’s high flexural modulus ensures it maintains its geometry over time. This is critical for snap-fit joints or spring-loaded clips; a Nylon clip may eventually “relax” and lose its clamping force, whereas a Delrin component retains its “spring-back” memory and structural rigidity indefinitely.

Fatigue Endurance: Which Material Lasts Longer in Cycling Parts?

For components undergoing repetitive cycling, such as gears, switches, or cams, Delrin offers world-class fatigue endurance. Its crystalline structure resists the micro-cracking that typically occurs after thousands of actuations.

While Nylon performs well in high-load static scenarios, Delrin’s ability to withstand millions of cycles without losing its tooth profile or dimensional accuracy makes it the preferred material for high-speed mechanical movements and precision instrumentation.

Tribology: Friction, Wear, and Self-Lubrication

Both materials are renowned for their self-lubricating properties, yet they behave differently under friction. In the Delrin vs Nylon tribological assessment, the decision rests on the required smoothness of motion and the presence of abrasive loads.

Static vs. Dynamic Friction: Avoiding the “Stick-Slip” Effect

Delrin possesses a lower coefficient of static friction compared to Nylon, making it the superior choice for slow-moving precision slides and actuators. Because its static and dynamic friction coefficients are nearly identical, Delrin eliminates the “stick-slip” effect that jerky, stuttering motion often felt when a part starts moving from a dead stop.

If your assembly requires glass-smooth startup and linear precision without the need for external grease, Delrin is the advisory standard.

Abrasive Wear: How Glass-Filled Nylon Changes the Game

When raw strength is insufficient, engineers often turn to glass-filled Nylon. This composite is a structural beast, offering significantly higher tensile strength and heat resistance. However, practitioners must be aware that glass fibers act as an internal abrasive.

Adding glass destroys the material’s natural self-lubricating properties and will rapidly accelerate wear on mating metal surfaces. Use glass-filled Nylon for stationary structural supports, but avoid it for high-speed rotating interfaces.

Bearing Performance: Choosing Materials for Bushings and Rollers

Selecting the right bearing material requires matching the polymer to the kinetic load:

- Low Load / High Speed: Select Delrin. Its superior heat dissipation and low friction prevent thermal buildup in fast-moving rollers.

- High Load / Low Speed: Select Nylon. Its higher compressive strength and toughness allow it to support heavier weights in bushings without crushing or deforming.

Thermal and Chemical Limits (2026 Standards)

Environmental survivability is the final gate in the Delrin vs Nylon selection process. Operating temperatures and chemical exposure frequently dictate the lifespan of engineering components in industrial and automotive sectors.

Heat Deflection: Operating Temperatures and Melting Points

Nylon is the clear victor for high-heat environments. It maintains structural integrity at a Continuous Service Temperature (CST) of 120°C to 150°C, making it the standard for under-the-hood automotive applications.

In contrast, Delrin is restricted to a lower CST of approximately 100°C. While Delrin has a sharp melting point, it begins to lose its characteristic stiffness much sooner than Nylon when approaching thermal thresholds.

For components near heat sources or internal combustion elements, Nylon’s thermal headroom prevents premature deformation.

Chemical Compatibility: Resistance to Fuels, Solvents, and Bases

Chemical resistance is highly specific to the polymer’s molecular bonds. Delrin is superior in fuels, solvents, and neutral organics, making it the primary choice for fuel sender units and gasoline caps. However, it is susceptible to strong acids and bases.

Conversely, Nylon offers better resistance to organic chemicals, oils, and greases, but it fails rapidly when exposed to strong mineral acids. Before finalizing your BOM, ensure the chosen plastic is inert to the specific cleaners or lubricants present in your 2026 operational environment.

UV Degradation: Outdoor Longevity and Weathering

When exposed to direct sunlight, both polymers require stabilization to prevent molecular “chain scission.”

Delrin is highly susceptible to UV degradation; without specific black-pigment stabilizers or UV inhibitors, it quickly develops a “chalky” surface, loses its characteristic impact strength, and eventually cracks.

While standard Nylon also degrades outdoors, it typically offers better baseline longevity than Delrin. However, for 2026 outdoor infrastructure, engineers should specify UV-stabilized (Black) Nylon or weatherable acetal grades.

If a part must survive years of high-UV exposure without a protective coating, the structural breakdown of unstabilized Delrin makes it a high-risk choice compared to carbon-black filled Nylon alternatives.

Manufacturing Reality: CNC Machining vs. 3D Printing

Transitioning from design to production reveals the starkest operational differences between Delrin vs Nylon. Your choice of manufacturing method, subtractive or additive, is often dictated by how these polymers react to heat and cutting forces.

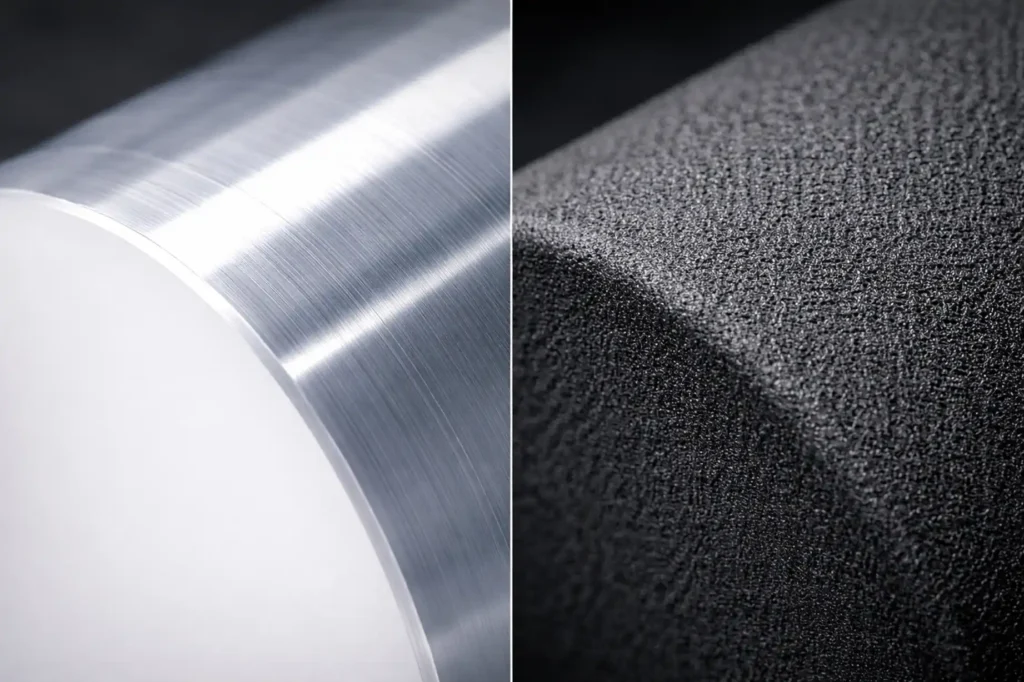

Machinability: Why Machinists Prefer the “Clean Chips” of Delrin

Delrin is the gold standard for high-speed CNC milling. Its high crystallinity allows it to shear cleanly, producing “chips” rather than long, tangled strings. This behavior ensures superior surface finishes and maintains +/- 0.001” tolerances with ease.

Conversely, Nylon is notoriously “gummy.” It tends to smear against the tool bit, creating significant burrs that require manual deburring.

To optimize Delrin machining, utilize sharp, polished carbide tools and high feed rates; slowing down too much increases friction, risking localized melting and dimensional “drift.”

3D Printing Challenges: Nylon’s Dominance in Additive Manufacturing

While Delrin wins in the machine shop, Nylon is the undisputed 2026 leader in additive manufacturing.

SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) technologies utilize Nylon to create high-strength, isotropic functional parts that rival injection molding.

Delrin remains extremely difficult to 3D print; its high shrink rate and poor interlayer adhesion lead to severe warping and structural failure.

If your workflow requires rapid, complex prototyping or small-batch additive production, Nylon is the only viable engineering-grade solution.

Post-Processing: Annealing, Dyeing (Nylon), and Surface Finishing

Post-production aesthetics and stability favor different materials. Nylon is highly receptive to chemical dyeing, allowing parts to be colored for branding or coding without affecting dimensions. It also benefits from annealing to relieve internal stresses.

Delrin, however, is chemically inert and “non-stick,” making it notoriously difficult to paint, bond, or dye. While its natural finish is smooth and professional, you are largely limited to the stock colors usually black or natural white available from the material supplier.

Application Showdown: Which One for Your Project?

Deciding between Delrin vs Nylon ultimately depends on the primary mechanical stress your component will face. Use the following categorized lists to align your material choice with industry-standard 2026 engineering applications.

Best for Gears, Valves, and High-Precision Instruments (Delrin)

Delrin is the superior choice for components where dimensional repeatability and low-friction motion are non-negotiable. Its rigidity ensures mechanical timing remains perfect over millions of cycles.

- Precision Gears & Cams: Maintains tooth profile and pitch under repetitive cycling.

- Fuel System Components: Resistant to gasoline and diesel without swelling.

- Electrical Switch Components: High dielectric strength paired with “snap-back” memory.

- Marine Hardware: Fittings and impellers that must operate submerged without seizing.

- Medical Delivery Devices: Ideal for small, intricate parts requiring tight biocompatible tolerances.

Best for Structural Housings, Pulleys, and Heavy-Duty Clips (Nylon)

Nylon is the preferred material for “high-abuse” parts that must absorb energy, resist heat, and survive environmental impact without fracturing.

- Automotive Engine Manifolds: Withstands continuous high-heat vibration in engine bays.

- Industrial Bushings: Supports heavy, slow-moving loads with high wear resistance.

- Power Tool Housings: Absorbs drops and internal motor heat during heavy use.

- Snap-Fit Fasteners: Flexible enough to bend and lock without snapping.

- Conveyor Rollers: Absorbs the shock of heavy loads in high-speed logistics.

Economic Considerations: Cost, Availability, and Sourcing

The financial justification for Delrin vs Nylon extends beyond the raw material invoice. Total part cost is heavily influenced by manufacturing throughput and yield rates.

Price per Pound vs. Total Part Cost (Scrap Rates)

While Delrin typically carries a higher price per pound than standard Nylon, it often yields a lower total part cost in CNC production. Delrin’s superior machinability allows for faster spindle speeds and reduced cycle times. Furthermore, its dimensional stability results in significantly lower scrap rates during high-tolerance inspections. When accounting for labor and machine time, the “premium” for Delrin is frequently offset by increased production efficiency.

Global Supply Chain Trends for POM and PA66 in 2026

In 2026, the supply chain for PA66 remains susceptible to precursor shortages, leading to occasional price volatility in the Nylon market.

Conversely, POM (Delrin) availability has stabilized globally due to expanded production capacity in North America and Asia. Engineers should prioritize Delrin for long-term, high-volume precision projects where price consistency is a critical budgetary requirement.

Final Verdict: The Decision Checklist

Select your material by isolating the primary environmental constraint of your application. Use this directive logic to finalize your 2026 design specifications:

- Need +/- 0.001” precision in high humidity? Select Delrin.

- Component must survive high-velocity impact or drops? Select Nylon.

- Designing for 3D printed functional prototypes (SLS/MJF)? Select Nylon.

- Application involves fuel, solvents, or submerged marine use? Select Delrin.

- Operating environment consistently exceeds 200°F (93°C)? Select Nylon.

- Requiring high-speed CNC production with zero deburring? Select Delrin.

FAQs

Is Delrin better than Nylon?

Neither material is strictly “better”; the choice depends entirely on the application’s primary need. Delrin is superior for precision and dimensional stability in wet environments, while Nylon is superior for high impact resistance and high heat applications.

Which is stronger, Delrin or Nylon?

Nylon (PA6/66) is generally stronger in terms of overall tensile strength (~12,000 psi) and impact resistance, allowing it to absorb more energy before failure. Delrin (POM) is stiffer and resists creep (deformation under constant load) better, making it feel more rigid and “metal-like.”

Does Delrin absorb more water than Nylon?

No, Delrin absorbs significantly less water. Nylon is hygroscopic and can absorb up to 8% moisture by weight, causing it to swell and lose stiffness. Delrin absorbs less than 0.2% of moisture, making it dimensionally stable in wet or humid environments.

Can you 3D print Delrin?

No, Delrin is extremely difficult to 3D print due to high warp rates and poor layer adhesion. Nylon is the standard engineering plastic for additive manufacturing technologies like SLS (Selective Laser Sintering) and MJF, producing robust functional parts.

Which is cheaper, Delrin or Nylon?

Nylon is typically cheaper per pound for raw stock material or injection molding. However, Delrin often results in lower total part cost during CNC machining due to faster cutting speeds, cleaner chips, and significantly lower scrap rates from precise tolerances.