HDPE vs. Delrin (Acetal): Engineering Guide for Performance, Cost, and Sustainability

Selecting the ideal thermoplastic for industrial applications requires a calculated trade-off between mechanical precision and environmental resilience.

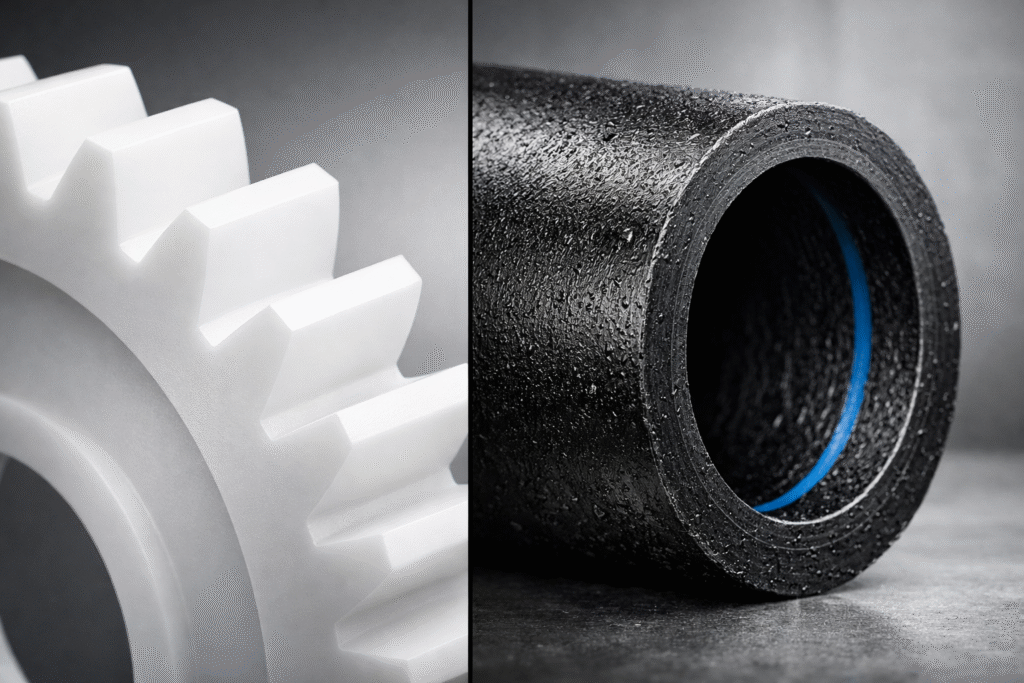

High-Density Polyethylene (HDPE) is a versatile, cost-effective polyolefin prized for its exceptional chemical immunity and high-impact toughness, making it the standard for fluid handling and heavy-duty storage.

Conversely, Delrin, a high-performance acetal homopolymer (POM-H), is engineered for rigorous mechanical duty, offering superior stiffness, dimensional stability, and natural lubricity.

In the advanced manufacturing landscape, the decision between the two rarely rests on cost alone; it is dictated by whether your application demands the uncompromising precision of Delrin or the robust chemical defiance of HDPE.

The Bottom Line: Quick Selection Matrix

Choosing between HDPE and Delrin requires a quick assessment of application priorities. While HDPE offers superior environmental toughness, Delrin is engineered for precision mechanical performance.

Choose HDPE When:

Cost, Impact Resistance, and Chemical Exposure Matter.

- Acid Exposure: Ideal for tanks and pipes exposed to strong acids, bases, and solvents.

- High Impact: Absorbs significant shock without cracking, perfect for protective guards and bumpers.

- Low Budget: Significantly more cost-effective for large-volume, non-precision parts.

- Outdoor/UV Use: Excellent resistance to weathering and sunlight exposure.

Choose Delrin When:

Precision, Stiffness, and Dimensional Stability Matter.

- Gears & Bushings: Excels in moving parts due to high strength and natural lubricity.

- <0.001” Tolerances: Maintains exact dimensions critical for precision machining and fit.

- Low Friction: Extremely low coefficient of friction (COF), often running without external lubrication.

- Load Bearing: High resistance to creep (permanent deformation) under continuous load.

| Property | HDPE (Polyethylene) | Delrin (Acetal/POM) | Winner |

| Tensile Strength | Lower (~4,000 psi) | High (~10,000 psi) | Delrin |

| Chemical Resistance | Excellent | Good | HDPE |

| Impact Resistance | Superior | Moderate | HDPE |

| Max Service Temp | ~65°C / 150°F | ~90°C / 194°F | Delrin |

| Machinability | Difficult (Gummy) | Excellent (Clean cuts) | Delrin |

| Dimensional Stability | Poor (High expansion) | Excellent | Delrin |

| Cost | Low | High | HDPE |

Mechanical Properties & Structural Integrity

The fundamental physics of HDPE and Delrin dictate their behavior under mechanical stress. While both are semi-crystalline plastics, their molecular density and intermolecular bonding create a sharp divide between “structural” and “utility” performance.

Strength-to-Weight Ratio and Stiffness

Delrin is defined by its high crystallinity, giving it a distinct “spring-like” quality. With a tensile strength of approximately 10,000 psi and a flexural modulus near 400,000 psi, Delrin behaves like a soft metal; it can be loaded heavily and will snap back to its original shape once the stress is removed.

In contrast, HDPE exhibits a “wax-like” ductility. Its tensile strength is significantly lower, typically hovering around 4,000 psi, with a flexural modulus of only 150,000 psi. While HDPE is lighter (specific gravity of 0.95 vs. Delrin’s 1.41), it lacks the internal architecture to support high-stress loads without stretching.

In applications where a part must resist bending or “give” under pressure, Delrin’s rigid molecular matrix is required.

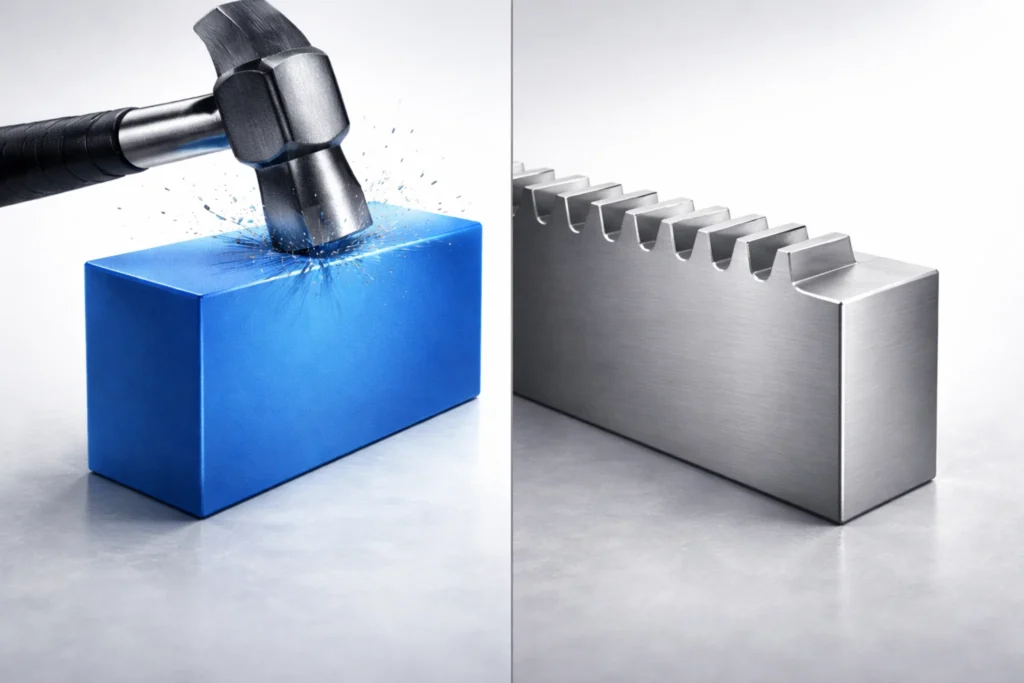

Impact Resistance and Energy Absorption

HDPE is the superior choice for high-energy absorption. Because its molecular chains are less tightly packed than Delrin’s, it can deform plastically to soak up the kinetic energy of an impact. This makes it the industry standard for “sacrificial” components like dock bumpers and wear strips.

Delrin, while tough, is notch-sensitive and relatively brittle in comparison. Under extreme, localized shock especially in cold environments, Delrin is susceptible to catastrophic cracking or shatteringg.

- HDPE Performance: Dents or deforms rather than breaking; maintains high toughness at sub-zero temperatures.

- Delrin Performance: Superior fatigue resistance (repeated small cycles) but prone to brittle failure under high-velocity impact.

Creep and Dimensional Stability

Engineering precision relies heavily on managing “creep” (the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses).

Delrin features exceptional “creep resistance” or material memory; it can hold a screw thread or a press-fit assembly for years without the material “migrating” away from the pressure.

HDPE, however, is highly prone to cold flow. Under continuous load, HDPE molecules will slowly slide past one another, leading to a permanent loss of part geometry and loosening of fasteners.

For any component requiring a precise, long term fit, HDPE’s lack of dimensional stability makes it a high-risk choice.

Machining Excellence: Efficiency and Precision

For the CNC machinist, the experience of cutting HDPE versus Delrin is a study in contrasts. While both are considered “free-machining” plastics, their thermal properties and chip formation dictate entirely different shop floor strategies to avoid scrapped parts.

Achieving Tight Tolerances

Delrin is the gold standard for plastic machining due to its exceptional dimensional stability. Its high crystallinity and low thermal expansion coefficient allow a skilled operator to comfortably hold tolerances of +/- 0.001″ or tighter.

In contrast, HDPE is notoriously difficult for precision work. Because it has a much higher coefficient of thermal expansion, the heat generated during the cutting process causes the material to expand significantly; once the part cools on the bench, it can “shrink” out of tolerance.

Furthermore, HDPE’s inherent internal stresses often cause thin-walled parts to warp immediately after being released from the workholding.

Surface Finish and Burring

The visual and tactile results of the two materials are vastly different. Delrin produces short, brittle “C-chips” that fly away from the cutter, leaving a crisp, matte, or semi-gloss finish with almost no burring on the exit edges.

Machining HDPE, however, often feels like carving wax. It tends to produce long, “stringy nests” that can wrap around the spindle and mar the surface finish. Because HDPE is ductile, the tool often “pushes” the material rather than shearing it, resulting in heavy, fuzzy burrs.

Achieving a clean edge on HDPE typically requires secondary manual deburring, whereas Delrin parts are often “flight-ready” straight from the machine.

Tooling and Thermal Management

To maximize throughput and part quality, machinists should follow these material-specific protocols:

- Use Up-Shear Geometry: For both materials, utilize polished, high-rake carbide tooling typically designed for aluminum to ensure the material is sheared cleanly rather than rubbed.

- Coolant is Mandatory for HDPE: While Delrin can often be machined dry, HDPE requires high-pressure flood coolant or a strong air blast to clear the stringy chips and prevent the material from melting onto the tool’s cutting edge.

- Aggressive Feed Rates: Both plastics have low melting points. To prevent “gumming,” use high feed rates to ensure the heat is carried away in the chip rather than dwelling in the part body.

- Sharpness is Key: Never use tools previously used on glass-filled plastics or metals; even microscopic dulling will cause HDPE to “smear” and Delrin to “chip.”

Tribology: Friction, Wear, and Motion Control

In mechanical design, the tribology of moving surfaces often dictates a component’s lifespan. Choosing between HDPE and Delrin for motion control involves weighing the need for “slip” against the cleanliness of the operating environment.

Coefficient of Friction and Self-Lubrication

Delrin is the undisputed leader in self-lubricating applications. Often referred to as “bridge plastic” because it mimics the smoothness of lubricated metal, Delrin’s molecular structure allows for extremely low stick-slip ratios. This “slip” advantage makes it ideal for precision bushings and high-speed gears where external grease is undesirable.

While HDPE also offers a low coefficient of friction (COF), it lacks the surface hardness to maintain that smoothness under high rotational speeds, often leading to “wiping” or material transfer.

| Material | Dynamic COF (Dry vs. Steel) | Static COF (Dry vs. Steel) |

| Delrin (POM) | 0.20 – 0.25 | 0.2 |

| HDPE | 0.25 – 0.30 | 0.3 |

Wear Rates in Abrasive vs. Sliding Environments

The winner of the “wear race” depends entirely on the presence of debris. In clean, sliding environments (such as a printer gear or a medical slide), Delrin’s superior hardness results in much lower wear rates over millions of cycles. However, in abrasive or “dirty” environments, the physics shift.

Because HDPE is softer and more ductile, it can “absorb” small particles of grit or sand into its surface, preventing them from acting as a grinding paste against the mating part. This “embeddability” makes HDPE the preferred choice for wear strips in agricultural machinery or conveyor guide rails where dust and particulates are unavoidable, as a harder Delrin surface would simply be scored and eroded by the trapped grit.

Environmental & Chemical Survival

Beyond mechanical loads, a material’s survival depends on its ability to withstand chemical degradation, fluid ingress, and thermal fluctuations.

In this arena, HDPE is a defensive powerhouse, while Delrin is a specialized performer that requires careful environmental monitoring.

Chemical Resistance Profile

HDPE is one of the most chemically inert thermoplastics available. Its non-polar molecular structure makes it virtually immune to most acids, bases, and cleaning agents.

Delrin, however, is vulnerable to strong acids and oxidizing agents, which can cause the polymer chains to unzip, leading to rapid embrittlement and part failure.

When designing for chemical plants or medical sterilization environments, the following resistance profile is critical:

| Chemical Agent | HDPE Resistance | Delrin (Acetal) Resistance |

| Bleach (Sodium Hypochlorite) | Excellent | Poor (Degrades) |

| Sulfuric Acid (Strong) | Excellent | Poor (Catastrophic Failure) |

| Gasoline / Diesel Fuel | Good | Excellent |

| Acetone / Solvents | Excellent | Excellent |

| Isopropanol (Alcohol) | Excellent | Excellent |

| Strong Bases (Sodium Hydroxide) | Excellent | Good |

Moisture Absorption and Hydrolytic Stability

Dimensional stability is often compromised by humidity. Delrin is slightly hygroscopic, meaning it absorbs moisture from the air (up to 0.25% by weight). While this seems small, it is enough to cause “swelling,” which can seize a tight-tolerance bushing or gear in high-humidity environments.

HDPE, conversely, is a total moisture barrier with near-zero absorption. It remains dimensionally consistent whether it is in a desert or submerged in the ocean, making it the superior choice for marine hardware.

Thermal Limits

Thermal management remains a primary constraint for polymer selection. Delrin offers a wider functional range for heat, whereas HDPE is limited to low-to-moderate temperature environments.

- HDPE Continuous Service Temp: ~65°C (150°F) Begins to soften significantly beyond this point.

- Delrin Continuous Service Temp: ~90°C (194°F) Maintains mechanical stiffness at higher thresholds.

- HDPE Melting Point: ~130°C (266°F).

- Delrin Melting Point: ~175°C (347°F).

2026 Compliance: Food Safety, Medical, and Sustainability

As regulatory landscapes tighten in 2026, material selection now mandates a focus on biocompatibility and environmental stewardship.

Both HDPE and Delrin offer compliant grades, but they serve different roles in the global supply chain’s “Green” initiatives.

FDA, NSF, and USP Class VI Compliance

In food processing and medical device manufacturing, “Natural” (unpigmented white) grades of both materials are the industry standard.

Natural HDPE is widely utilized for its FDA and NSF compliance, appearing in everything from commercial cutting boards to fluid manifolds, as it does not leach chemicals into organic matter.

Similarly, Delrin (POM-H) is available in medical-grade formulations that meet USP Class VI standards, making it suitable for surgical instruments and orthopedic trials.

However, engineers must be cautious: while the base resins are often safe, specific additives or “black” variants may contain carbon black or stabilizers that void these certifications. Always verify the specific lot’s 2026 compliance certificate before production.

Circular Economy: Recyclability and Carbon Footprint

In the era of ESG (Environmental, Social, and Governance) reporting, HDPE is the clear “Eco-Winner.” As a #2 Plastic, HDPE has the most established recycling infrastructure in the world, allowing manufacturers to utilize “Post-Consumer Recycled” (PCR) resins for non-critical parts, drastically lowering their carbon footprint.

Delrin, while technically a thermoplastic, is rarely recycled through municipal streams and requires specialized industrial processes to reprocess. However, Delrin’s “green” value lies in its lifecycle longevity. Because Delrin parts are exceptionally durable and fatigue-resistant, they often outlast HDPE components by a 5-to-1 ratio, reducing the total volume of waste generated over the life of a machine.

For 2026 projects, HDPE is the choice for circularity, while Delrin is the choice for durability.

The Economic Analysis: Part Cost vs. Lifecycle Value

For procurement officers, the “cheapest” material on a quote often hides the true cost of production. A sophisticated financial analysis must look past the price per pound of raw resin to the total landed cost of the finished component.

Raw Material Price vs. Machining Labor Costs

On a raw material basis, HDPE is significantly more affordable, typically costing 3 to 5 times less than Delrin per kilogram.

However, for CNC-machined parts, the material cost is only one variable. Delrin’s superior machinability allows for much higher spindle speeds and feed rates, drastically reducing “cycle time” on the machine. Furthermore, Delrin produces clean edges that rarely require manual deburring.

Conversely, the labor costs associated with managing HDPE’s stringy chips and the secondary operations needed to remove “fuzz” can bridge the price gap. For complex geometries, the efficiency of machining Delrin often makes the final part price comparable to—or even cheaper than—HDPE.

Replacement Frequency and Maintenance Savings

The “Cost of Failure” is the most overlooked metric in industrial procurement. While an HDPE bushing may save $50 in initial acquisition costs, its tendency to “creep” or wear prematurely in high-load applications can lead to catastrophic machine downtime.

In 2026, where specialized labor for maintenance is at a premium, the durability of Delrin provides a massive ROI. Because Delrin maintains its tolerances and resists fatigue, the replacement frequency is significantly lower.

Choosing Delrin for critical-path mechanical components is an investment in maintenance-free operation, whereas HDPE is better suited for low-risk, high-volume consumables where frequent replacement is already factored into the operational budget.

Failure Modes: What Could Go Wrong?

Engineering success relies as much on understanding material limits as it does on leveraging their strengths. Both HDPE and Delrin possess “hidden” failure modes that can lead to catastrophic part rejection if not accounted for during the design phase.

Environmental Stress Cracking (ESC)

While HDPE is celebrated for its chemical resistance, it is uniquely vulnerable to Environmental Stress Cracking (ESC). This phenomenon occurs when the material is under constant mechanical stress and is simultaneously exposed to seemingly harmless “surface-active” agents, such as industrial detergents, alcohols, or certain oils. These substances accelerate the formation of microscopic brittle cracks that can propagate through a part without warning.

In 2026, designers must ensure that HDPE components in high-load applications like pressurized fluid manifolds are kept away from aggressive surfactant cleaners to avoid sudden, brittle fracturing in what is usually a ductile material.

Centerline Porosity in Delrin

A critical risk for CNC machinists is the “Centerline Porosity” inherent in the manufacturing of thick Delrin (POM-H) shapes.

During the extrusion process, the outer layers of a Delrin slab or rod cool faster than the core, causing the center to contract and create a line of microscopic voids or “air gaps.” If a machinist bores into the center of a thick Delrin rod, they may encounter these pits, which compromise seal integrity and provide a breeding ground for bacteria in medical or food-grade applications.

To mitigate this, engineers should specify “Acetal Copolymer” (POM-C) for thick-walled parts or use Delrin only when the design allows for the removal of the porous center.

Final Verdict: Which Material Wins Your Project?

Choosing between HDPE and Delrin requires balancing cost efficiency against mechanical requirements. Both materials are indispensable, but their success depends on the environment they occupy.

The Industrial Standard for Heavy-Duty Chemical Handling

HDPE is the definitive winner for applications where chemical immunity and impact toughness are the primary requirements. If your project involves large-scale fluid storage, acidic environments, or components that must survive significant physical abuse without fracturing, HDPE’s ductility and budget-friendly profile make it the logical choice.

Its 2026 status as a highly recyclable material also ensures compliance with modern sustainability mandates for high-volume industrial consumables.

The Precision Standard for Mechanical Engineering

Delrin remains the superior choice for high-performance mechanical components that demand “metal-like” behavior. When your design requires tight tolerances, high-speed rotation, or the ability to maintain structural stiffness under persistent loads, Delrin’s natural lubricity and creep resistance are unmatched.

While the initial material cost is higher, its excellence in CNC machining and its long-term lifecycle durability provide the lowest total cost of ownership for precision engineering projects.

FAQs

Is Delrin stronger than HDPE?

Yes, Delrin is significantly stronger than HDPE, with a tensile strength of approximately 10,000 psi compared to HDPE’s 4,000 psi. While Delrin offers superior stiffness and load-bearing capacity for structural parts like gears, HDPE provides much higher impact resistance, making it less likely to crack under sudden shock or heavy blows.

Can you machine HDPE as easily as Delrin?

While both can be machined, Delrin is much easier to machine to tight tolerances (+/- 0.001″) because it is rigid and produces clean, brittle chips. HDPE is a “gummy” plastic that produces long, stringy nests and burrs, often requiring secondary deburring and specialized high-rake tooling to achieve a professional surface finish.

Which material is better for food-safe applications, HDPE or Delrin?

Both materials have FDA-compliant natural grades, but they serve different roles: HDPE is the industry standard for commercial cutting boards and storage containers due to its chemical immunity and low cost. Delrin is preferred for high-precision food processing components, such as conveyor rollers and filling machine gears, where mechanical wear resistance and dimensional stability are required.

Does Delrin absorb more water than HDPE?

Yes, Delrin is slightly more hygroscopic than HDPE, with a moisture absorption rate of about 0.25%, which can cause minor dimensional swelling in submerged environments. HDPE is a near-total moisture barrier with zero absorption, making it the superior choice for marine applications or parts that must remain dimensionally identical in high-humidity conditions.

Why is Delrin more expensive than HDPE?

Delrin is an engineering-grade thermoplastic with a higher manufacturing cost and a density of 1.41 g/cm³, whereas HDPE is a high-volume commodity plastic with a lower density of 0.95 g/cm³. While Delrin’s raw material cost is higher, it often reduces total part cost by allowing for faster CNC machining speeds and lower maintenance cycles in high-precision assemblies.

Is HDPE more eco-friendly than Delrin?

In terms of the circular economy, HDPE is more environmentally friendly because it is a #2 recyclable plastic with a globally established recycling infrastructure. While Delrin is highly durable and lasts longer in service (reducing waste frequency), it is much more difficult to recycle and typically requires specialized industrial processes to re-enter the production cycle.