Nylon 6 vs Nylon 12: Which Polyamide Is the Better Choice for Your Application?

Your component just failed hydrolytic degradation testing after six months in a humid enclosure. You specified PA6 for its superior tensile modulus and lower resin cost but ignored moisture absorption rates.

Specifying Nylon 6 vs Nylon 12 is not an academic exercise; the choice dictates your warranty claims, field reliability, and total material spend.

PA6 delivers exceptional mechanical strength at half the cost of PA12. But that economic advantage evaporates when dimensional stability collapses under moisture exposure or elevated service temperatures.

PA12 resists environmental stress but demands budget justification. Choose wrong, and you’re redesigning tooling or managing product recalls.

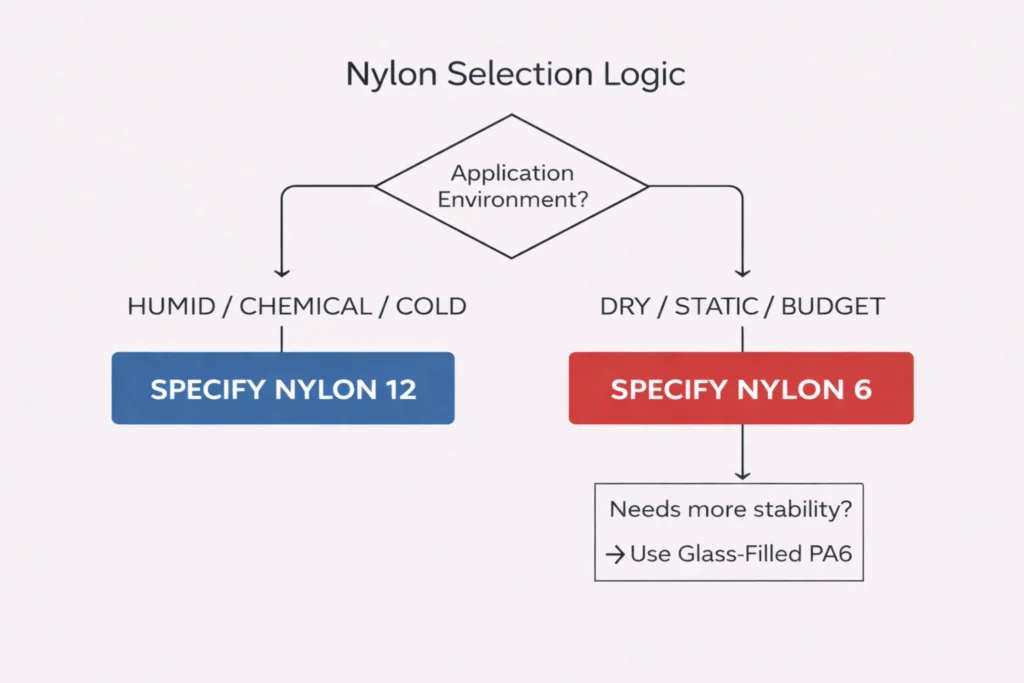

The trade-off is binary: economic strength with PA6 versus environmental stability with long-chain PA12. Your application parameters not material popularity must drive the specification.

Core Material Differences That Drive Selection

Polymer Structure and Molecular Weight Impact

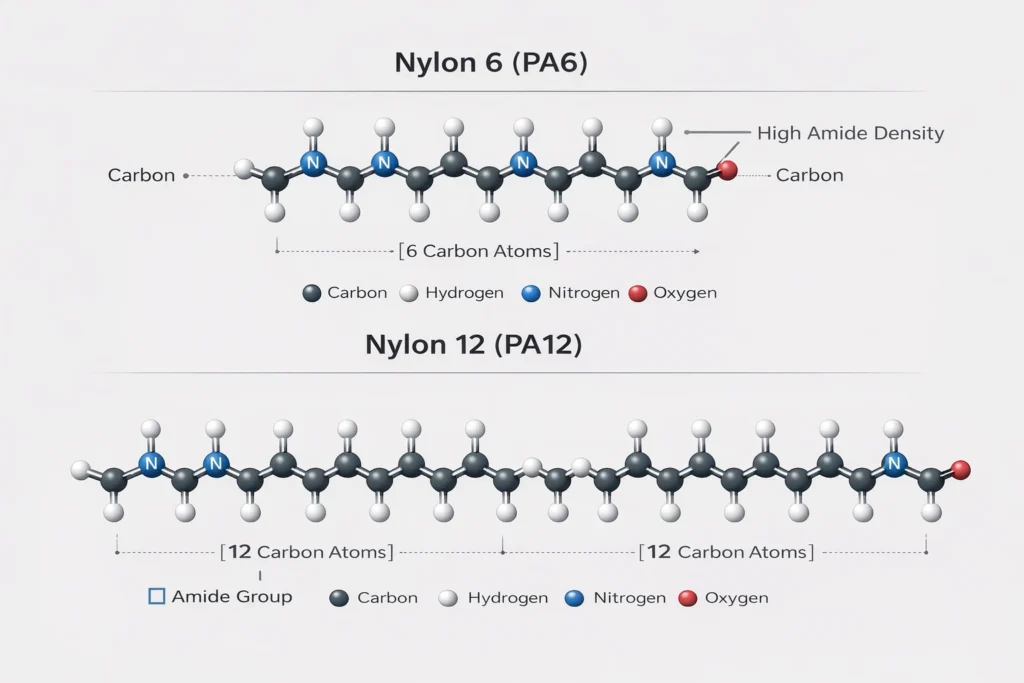

The fundamental distinction lies in the monomer repeat unit. PA6 derives from caprolactam with six carbon atoms per amide group, creating a short-chain polyamide with densely packed hydrogen bonds.

PA12, synthesized from laurolactam, spaces amide groups across twelve carbon atoms. This extended hydrocarbon segment reduces hydrogen bonding density by approximately 50%.

The consequence? PA6 exhibits higher crystallinity (35–45%) compared to PA12’s 30–35% range. Tighter molecular packing elevates the glass transition temperature and tensile modulus in short-chain variants.

Conversely, the longer aliphatic segments in PA12 provide molecular flexibility and lower moisture affinity. The carbon-to-amide ratio governs every downstream property from hydrophilic behavior to chemical resistance.

Mechanical Strength and Toughness Comparison

- Tensile Strength: PA6 delivers 80–85 MPa in dry-as-molded condition versus 55–60 MPa for PA12. When absolute yield stress drives your design envelope, specify the short-chain polyamide.

- Impact Resistance: PA12 absorbs 6–8 kJ/m² (Charpy notched) at -40°C, while PA6 drops to 3–4 kJ/m² under identical conditions. For sub-zero service environments, the long-chain variant prevents brittle fracture.

- Stiffness Trade-Off: Base resin PA6 records a tensile modulus near 3,200 MPa; PA12 measures 1,600 MPa. Higher stiffness translates to deflection control but sacrifices ductility under shock loading.

PA6 wins static structural applications. PA12 dominates impact and low-temperature toughness requirements.

Flexibility and Fatigue Resistance Differences

Elongation at break separates these materials under cyclic loading. PA6 achieves 30–40% strain before failure in tensile tests, whereas PA12 reaches 50–300% depending on grade and conditioning. This ductility advantage extends fatigue life in vibration-prone assemblies like automotive clips or living hinges.

The flexural modulus gap is decisive: PA6 registers 2,800–3,000 MPa compared to PA12’s 1,400–1,500 MPa. Lower rigidity in the long-chain variant permits elastic deformation without crack initiation.

For components enduring repetitive flex cycles snap-fit connectors, cable jacketing, or bellows PA12 delays fatigue failure by 2–3× versus short-chain alternatives. When dimensional recovery after deflection matters more than absolute stiffness, pivot to the twelve-carbon backbone.

Moisture Absorption and Dimensional Stability

Water Uptake Rates and Performance Degradation

| Condition | PA6 Saturation | PA12 Saturation | Time to Equilibrium |

| 23°C / 50% RH | 2.80% | 0.25% | 10–14 days |

| Water Immersion (23°C) | 9.50% | 1.60% | 30–45 days |

| 85°C / 85% RH | 3.50% | 0.40% | 7 days |

PA6 absorbs eleven times more water than PA12 at saturation under standard atmospheric conditions. Each absorbed water molecule disrupts hydrogen bonding between polymer chains, creating a plasticizing effect. The consequence is measurable: tensile strength drops 15–20%, elongation increases 40–60%, and the material softens noticeably.

The long-chain variant resists this degradation. PA12’s hydrophobic aliphatic segments reject moisture penetration, preserving as-molded mechanical properties across humidity swings. When your component operates in uncontrolled environments, HVAC enclosures, outdoor electronics, or tropical climates the short-chain polyamide introduces unacceptable performance drift. Specify PA12 when moisture conditioning isn’t feasible.

Dimensional Stability in Humid and Wet Environments

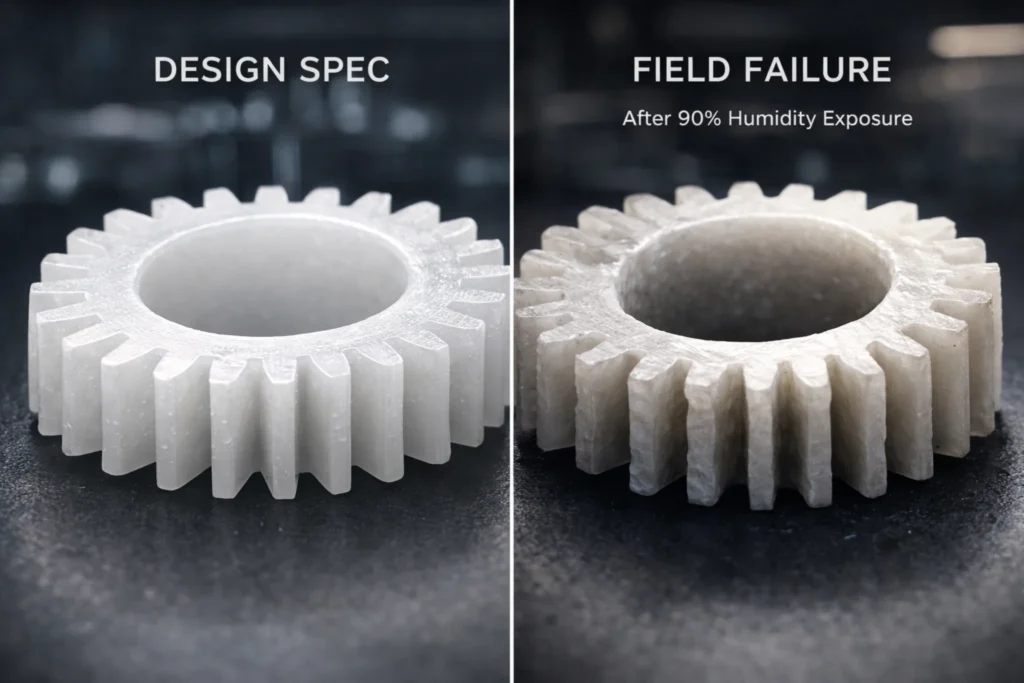

Hygroscopic expansion destroys precision assemblies. PA6 swells 0.8–1.2% linearly after water saturation compared to 0.15–0.25% for PA12. On a 100 mm molded gear, that translates to 0.8–1.2 mm growth enough to bind assemblies, create backlash, or fracture interference fits.

The mechanism is straightforward: absorbed water molecules occupy interstitial space between polymer chains, forcing physical expansion. High-humidity zones amplify this effect. A PA6 housing designed with ±0.1 mm tolerances in a climate-controlled facility will measure out-of-spec within weeks of deployment in coastal or tropical regions.

Heat deflection temperature (HDT) collapses simultaneously. Dry PA6 maintains rigidity to 65–75°C; moisture-saturated samples soften at 45–50°C. PA12 retains structural integrity to 55–60°C even after full conditioning.

For applications demanding dimensional repeatability across temperature and humidity swings, the long-chain variant is mandatory.

When Moisture Sensitivity Becomes a Deal-Breaker

Certain applications prohibit PA6 regardless of cost advantages. Specify PA12 or alternative engineering thermoplastics when:

- Precision gearing in marine environments: Salt spray accelerates hydrolysis; PA6 degrades within 18–24 months while PA12 survives 5+ years.

- Tight-tolerance bushings or bearings: Dimensional growth exceeds clearance specs, causing seizure or accelerated wear.

- Outdoor electrical enclosures: UV exposure combined with moisture creates surface cracking and embrittlement in short-chain polyamides.

- Fuel system components: Hydrolytic degradation in PA6 releases oligomers that contaminate fuel; PA12 resists chemical attack.

- Medical devices requiring steam sterilization: Repeated autoclaving at 121°C + moisture destroys PA6 molecular weight; PA12 withstands 200+ cycles.

- Pneumatic tubing in humid factories: Pressure retention depends on stiffness; moisture-plasticized PA6 creeps under continuous load.

If your application involves uncontrolled humidity, aqueous chemical contact, or steam exposure, eliminate PA6 from consideration immediately.

Thermal and Chemical Performance Limits

Operating Temperature Ranges (Short-Term vs Continuous)

PA6 tolerates higher thermal loads in dry conditions. The melting point reaches 220°C compared to PA12’s 178°C, creating a wider processing window for injection molding and enabling short-term exposure to elevated temperatures. Heat deflection temperature (HDT) for dry PA6 measures 65–75°C at 1.8 MPa, while PA12 registers 55–60°C under identical loading.

This apparent advantage collapses under moisture conditioning. Conditioned PA6 drops to 45–50°C HDT, making it unsuitable for under-hood automotive applications or electronics subjected to thermal cycling. PA12 maintains 50–55°C HDT even after saturation, providing more predictable performance across humidity variations.

For continuous service, limit PA6 to 80–90°C in dry environments and 60–70°C when moisture exposure is unavoidable. PA12 operates reliably to 80–100°C regardless of conditioning, making it preferable for components near heat sources or in uncontrolled thermal environments. Glass-filled grades extend these thresholds by 15–20°C but introduce brittleness and anisotropic shrinkage during molding.

Chemical Resistance to Oils, Fuels, and Solvents

PA12 dominates hydrocarbon environments. The extended aliphatic chain resists swelling and stress cracking when exposed to gasoline, diesel, hydraulic fluids, and mineral oils. Automotive fuel lines universally specify the long-chain variant because PA6 absorbs fuel additives, leading to dimensional instability and permeation failures.

Short-chain polyamides excel against weak acids, alkalis, and alcohols but degrade rapidly in polar solvents like formic acid or phenols. PA12 withstands prolonged exposure to brake fluids, motor oils, and biodiesel blends without mechanical property loss, critical for fluid handling systems.

One exception: both variants suffer hydrolysis in hot water or steam above 80°C. If your application involves continuous aqueous contact at elevated temperatures, pivot to polyphthalamide (PPA) or polyphenylene sulfide (PPS). For fuel contact, chemical transfer lines, or oil-wetted gears, PA12 is mandatory. PA6 introduces unacceptable risk of permeation and chemical attack.

Performance in Outdoor and Harsh Environments

Unprotected polyamides degrade under UV radiation, but stabilization packages mitigate this weakness. Specify UV-stabilized grades containing carbon black or hindered amine light stabilizers (HALS) for exterior applications. Without additives, both PA6 and PA12 exhibit surface chalking and embrittlement after 12–18 months of direct sunlight exposure.

PA12 resists environmental stress cracking more effectively than short-chain alternatives. The inherent flexibility prevents crack propagation when components experience combined chemical exposure and mechanical stress, common in agricultural equipment, outdoor power tools, and marine hardware.

For coastal or industrial atmospheres, PA12’s lower moisture uptake prevents salt crystallization within the polymer matrix, extending service life by 2–3× compared to PA6. Deploy the long-chain variant when replacement access is limited or when warranty costs justify the material premium.

Processing and Manufacturing Considerations

Injection Molding Behavior and Cycle Stability

Mold shrinkage differentiates these materials significantly. PA6 shrinks 1.0–1.5% in the flow direction and 1.2–1.8% transverse to flow, creating anisotropic part distortion that complicates tight-tolerance tooling.

PA12 exhibits 0.5–1.0% shrinkage with superior isotropy, enabling more predictable dimensional outcomes and reducing mold iteration cycles.

Processing temperature windows compound this difference. PA6 requires melt temperatures of 230–280°C with mold surfaces at 80–90°C to prevent premature solidification. PA12 processes at 200–240°C with 40–60°C mold temperatures, reducing energy consumption and cycle times by 12–18%.

The short-chain polyamide demands rigorous drying protocols, below 0.1% moisture content before processing to prevent hydrolytic chain scission and surface defects. PA12 tolerates 0.15% moisture without degradation, simplifying material handling. For high-volume production where cycle consistency and minimal tool maintenance matter, PA12 delivers superior process stability despite higher resin cost.

Machining Characteristics and Surface Finish

- Chip Formation: PA12 produces long, stringy chips that require interrupted cutting; PA6 generates brittle chips with cleaner tool disengagement.

- Tool Wear: The higher crystallinity of PA6 accelerates carbide insert wear by 20–30% versus PA12 when turning or milling at equivalent speeds.

- Burr Tendency: PA12’s ductility creates more burrs at part edges during drilling operations; PA6 yields cleaner holes but risks microcracking under excessive feed rates.

- Surface Finish: PA12 achieves Ra 0.8–1.2 μm with standard turning; PA6 delivers 0.6–0.9 μm due to reduced elastic recovery after tool passage.

- Thermal Management: Both materials require coolant or air blast to prevent heat buildup; PA12 softens more readily, demanding conservative cutting parameters for dimensional control.

3D Printing Compatibility (SLS, MJF, Extrusion)

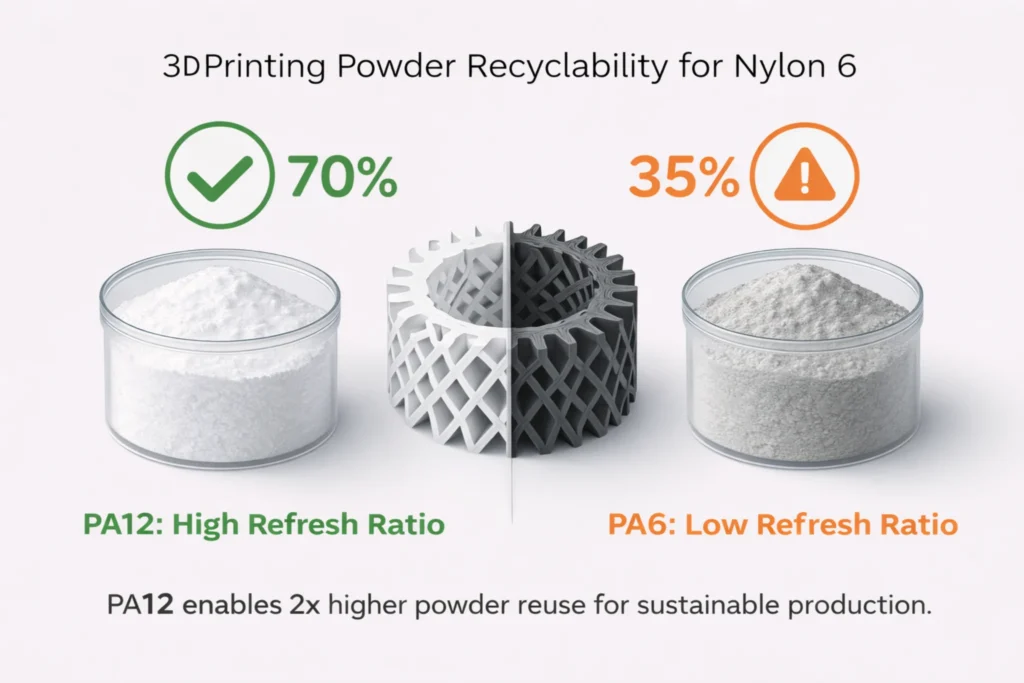

PA12 has become the gold standard for powder bed fusion processes including Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). The material’s narrow melting range (172–178°C) and controlled crystallization kinetics enable consistent layer adhesion without warping, critical for complex geometries.

In MJF systems, PA12 dominates due to superior powder refresh ratios. Unsintered powder can be recycled at 50–70% blend rates with virgin material while maintaining mechanical properties within specification. PA6 powder degrades more rapidly under thermal cycling, limiting refresh ratios to 30–40% and increasing material waste costs.

Fused filament fabrication (FFF) presents challenges for both variants. PA6 requires enclosed chambers maintaining 60–80°C ambient temperature to prevent warping; PA12 tolerates 40–60°C, expanding compatible printer options. Both materials demand desiccant storage and heated build plates.

For production-scale additive manufacturing, specify PA12 for MJF applications targeting functional prototypes or end-use parts. The material enables isotropic mechanical properties approaching 85–90% of injection-molded strength, acceptable for low-volume production runs, tooling fixtures, or customized medical devices. PA6 remains a niche option for SLS when higher stiffness justifies the powder refresh penalty.

Cost, Availability, and Supply Chain Factors

Raw Material Cost Differences and Price Stability

PA12 commands 2–3× the price of PA6 on a per-kilogram basis. Commodity PA6 resin trades at $3.20–$4.50/kg, while standard PA12 ranges $8.50–$12.00/kg depending on supplier and volume commitments. Specialty grades with impact modifiers or flame retardants widen this gap further.

Price volatility differs significantly. PA6 pricing tracks crude oil and benzene markets with 15–25% annual fluctuation. PA12, derived from butadiene via a more complex synthesis pathway, exhibits narrower volatility (8–15%) but remains subject to supply concentration risk, three suppliers control 70% of global capacity.

For budget-constrained applications where moisture and chemical exposure are controlled, PA6 delivers acceptable performance at half the material cost. When performance failures trigger warranty claims, field replacements, or safety incidents, the resin delta becomes immaterial.

Sustainability Profiles: Bio-based PA12 vs. Recycled PA6

The sustainability landscape favors both materials depending on corporate carbon accounting methods. Bio-based PA12, synthesized from castor oil rather than petrochemical butadiene, reduces carbon footprint by 40–50% compared to fossil-derived variants. Major suppliers now offer grades with 60–100% renewable carbon content, meeting EU taxonomy requirements for sustainable products.

Recycled PA6 presents an alternative pathway. Post-consumer fishing nets and ocean plastics yield mechanically recycled resin at 25–35% lower embodied carbon than virgin material. However, contamination and molecular weight degradation limit recycled content to 20–30% blends in structural applications without performance compromise.

From a lifecycle perspective, PA12’s extended service life in harsh environments may offset higher production emissions. A fuel line lasting 15 years versus a PA6 alternative requiring replacement at 6 years shifts the total carbon equation.

Regulatory drivers matter. California and EU markets increasingly mandate recycled content disclosure. PA6 supply chains offer broader access to certified recycled grades. Bio-based PA12 targets applications where renewable sourcing justifies price premiums, medical devices, consumer electronics, and luxury automotive.

Availability of Filled and Specialty Grades

PA6 enjoys off-the-shelf availability across glass-filled (15–50%), mineral-filled, and impact-modified variants from multiple global suppliers. Lead times for standard grades remain 2–4 weeks even for moderate volumes (5–20 metric tons).

PA12 specialty formulations, UV-stabilized, flame-retardant (V0), or elastomer-modified grades often require custom compounding with 8–12 week lead times and minimum order quantities of 1–2 metric tons. This supply chain reality complicates prototyping and low-volume production.

Glass-reinforced PA12 presents processing challenges. The material’s lower melt temperature limits filler loading to 30–35% before brittleness becomes unacceptable, versus 50% achievable in PA6 compounds. For maximum stiffness applications, the short-chain polyamide provides superior reinforcement potential.

Long-Term Cost of Ownership in Production

Total cost analysis reverses the apparent price disadvantage of PA12 in demanding applications. Calculate the equation correctly:

A PA6 fuel connector costing $2.40 in material versus a PA12 variant at $6.80 appears expensive until field failures trigger recalls. One warranty event averaging $850 per vehicle (labor + parts + logistics) across 5,000 units erases the savings from 180,000 connectors.

PA12’s dimensional stability eliminates secondary machining operations on precision components. When post-molding tolerances hold without grinding or heat treatment, labor cost reductions of $0.80–$1.50 per part offset material premiums on production volumes exceeding 50,000 units annually.

Tooling longevity extends further with the long-chain variant. Lower processing temperatures and reduced abrasiveness increase mold life by 25–40%, deferring capital expenditures on tool replacements. For programs spanning 5+ years, amortize tooling savings into your material decision matrix.

Typical Applications Where Each Material Wins

Applications Best Suited for Nylon 6

- Under-hood engine covers in dry-heat zones requiring stiffness and flame resistance

- Power tool housings benefiting from high impact strength and low cost in climate-controlled storage

- Structural brackets and mounting bosses where insert retention and creep resistance matter

- Electrical connectors in indoor HVAC systems with stable humidity

- Conveyor components and wear pads operating in dry industrial facilities

- Textile and carpet fibers leveraging PA6’s excellent dyeability

- High-volume consumer goods (appliance parts, furniture components) where cost pressure dominates

- Gears and bushings in sealed gearboxes protected from moisture ingress

Applications Where Nylon 12 Outperforms

- Automotive fuel lines and vapor barriers requiring hydrocarbon resistance and zero permeation

- Air brake tubing in commercial vehicles demanding flexibility at -40°C

- Medical catheters and surgical tubing needing biocompatibility and sterilization durability

- Pneumatic tubing in humid factories where dimensional stability prevents pressure loss

- MJF and SLS 3D-printed end-use parts for customized production runs

- Cable jacketing for outdoor telecommunications exposed to UV and moisture

- Fluid reservoirs and tanks in contact with oils, coolants, or chemical additives

- Precision bushings in marine environments where salt spray accelerates corrosion

- Ski boot shells and athletic equipment requiring low-temperature toughness

Nylon 6 vs Nylon 12: Direct Decision Matrix

Quick Selection Guide Based on Operating Conditions

| Operating Condition | Recommended Material | Why |

| Dry, indoor, <70°C | PA6 or PA6-GF30 | Cost advantage outweighs performance delta; controlled environment negates moisture risk |

| Humidity >60% RH | PA12 | Hygroscopic expansion in PA6 destroys tolerances; dimensional drift causes assembly issues |

| Direct fuel/oil contact | PA12 (mandatory) | Hydrocarbon resistance prevents swelling; PA6 suffers permeation and chemical degradation |

| Impact below -20°C | PA12 | Ductility at sub-zero temps prevents brittle fracture; PA6 fails Charpy testing |

| High stiffness, dry heat | PA6-GF30 or PA6-GF50 | Glass reinforcement delivers modulus >9,000 MPa at fraction of PA12 cost |

| Tight tolerances, outdoor | PA12 or PA6-CF30 | Low moisture uptake maintains dimensions; carbon fiber limits PA6 expansion to acceptable levels |

| Cyclic flexing/living hinge | PA12 | Elongation at break (50–300%) delays fatigue crack initiation by 2–3× versus PA6 |

| Steam sterilization | PA12 (>200 cycles) | Resists hydrolytic degradation at 121°C; PA6 molecular weight collapses after 50 cycles |

| Budget-critical, high volume | PA6 | Resin cost $3.50/kg vs $10/kg enables margin preservation in price-sensitive markets |

| MJF/SLS 3D printing | PA12 (industry standard) | Powder refresh ratios 50–70%; consistent sintering; isotropic properties approach injection molding |

Final Recommendation: Which One Should You Choose?

Choose Nylon 6 If These Conditions Matter Most

- Material budget constrains program viability: Resin cost at $3.50–$4.50/kg enables margin preservation in high-volume production.

- Stiffness governs deflection limits: Tensile modulus of 3,200 MPa (9,000+ MPa glass-filled) controls dimensional precision under static loads.

- Operating environment remains dry and climate-controlled: Humidity below 40% RH negates hygroscopic expansion risks.

- Elevated heat exposure in moisture-free zones: Melting point at 220°C and dry HDT of 75°C exceed PA12 thermal thresholds.

- Supply chain velocity matters: Off-the-shelf availability and 2–4 week lead times accelerate production ramp.

Choose Nylon 12 If These Requirements Are Critical

- Dimensional stability cannot tolerate moisture drift: Hygroscopic expansion limited to 0.15–0.25% preserves tight tolerances across humidity swings.

- Chemical exposure includes fuels, oils, or hydraulic fluids: Hydrocarbon resistance prevents permeation failures and swelling degradation.

- Service temperature spans sub-zero conditions: Impact toughness at -40°C (6–8 kJ/m² Charpy) prevents brittle fracture in cold environments.

- Cyclic loading or flex fatigue dominates failure mode: Elongation at break (50–300%) extends fatigue life 2–3× versus short-chain alternatives.

- Field replacement costs exceed material premium: One warranty event erases savings from thousands of components, specify reliability over initial cost.

FAQs

Is Nylon 6 or Nylon 12 better for automotive fuel systems?

Nylon 12 (PA12) is mandatory for fuel systems due to its superior resistance to hydrocarbons and road salts (zinc chloride), which cause stress cracking in Nylon 6. PA12 also offers the lowest moisture absorption (~0.25%), preventing the swelling and leak paths common with PA6 fuel connectors.

What is the biggest difference between PA6 and PA12 in 3D printing?

The primary difference is dimensional stability and recyclability. PA12 has a higher powder refresh ratio (up to 70% reuse) in MJF/SLS compared to PA6 (~30–40%). Furthermore, PA12 warps significantly less during printing because its long-chain structure absorbs 10x less moisture than PA6.

Why is Nylon 12 more expensive than Nylon 6?

Nylon 12 is roughly 2–3x more expensive because of its complex synthesis pathway starting from butadiene and its limited global supply chain. The premium price is justified in applications requiring precision tolerances in humid environments where PA6 would fail.

Can glass-filled Nylon 6 replace Nylon 12 to save costs?

Yes, in specific cases. Reinforcing Nylon 6 with 30%–50% glass fiber (PA6-GF) significantly increases stiffness and reduces moisture-induced warping, allowing it to mimic the dimensional stability of PA12 at a lower price point. However, it remains susceptible to road salts and chemical degradation where PA12 is immune.

Which nylon has better heat resistance?

Nylon 6 (PA6) has superior heat resistance for dry environments with a melting point of 220°C–230°C, compared to 178°C–180°C for Nylon 12. However, if the heat is combined with high humidity, PA12 often performs better long-term because its properties do not collapse due to moisture absorption.