SLS vs FDM: Which 3D Printing Technology Is Right for Your Application?

To choose between these technologies, evaluate your requirement for mechanical isotropic strength versus cost-effective scale. FDM (Fused Deposition Modeling) is the industry standard for low-cost, large-scale visual prototyping and simple jigs, while SLS (Selective Laser Sintering) is the superior choice for complex, high-performance functional parts and high-density batch production.

In this technical SLS vs FDM comparison, we move past the basics to analyze the precise thresholds of ROI, geometric limits, and material durability that determine which technology delivers the highest value for your specific engineering or manufacturing workflow.

Decision Snapshot: SLS vs FDM at a Glance

This table provides an immediate technical breakdown to assist in rapid technology selection. Use this as a baseline for determining which process aligns with your project’s mechanical requirements and budgetary constraints.

| Feature | FDM (Fused Deposition Modeling) | SLS (Selective Laser Sintering) | Winner |

| Best For | Basic prototyping & large, simple jigs | Functional parts & complex batch production | Tie (Based on Use) |

| Material | Thermoplastic Filaments (PLA, ABS, PEEK) | Polymer Powders (Nylon PA11, PA12) | FDM (Variety) |

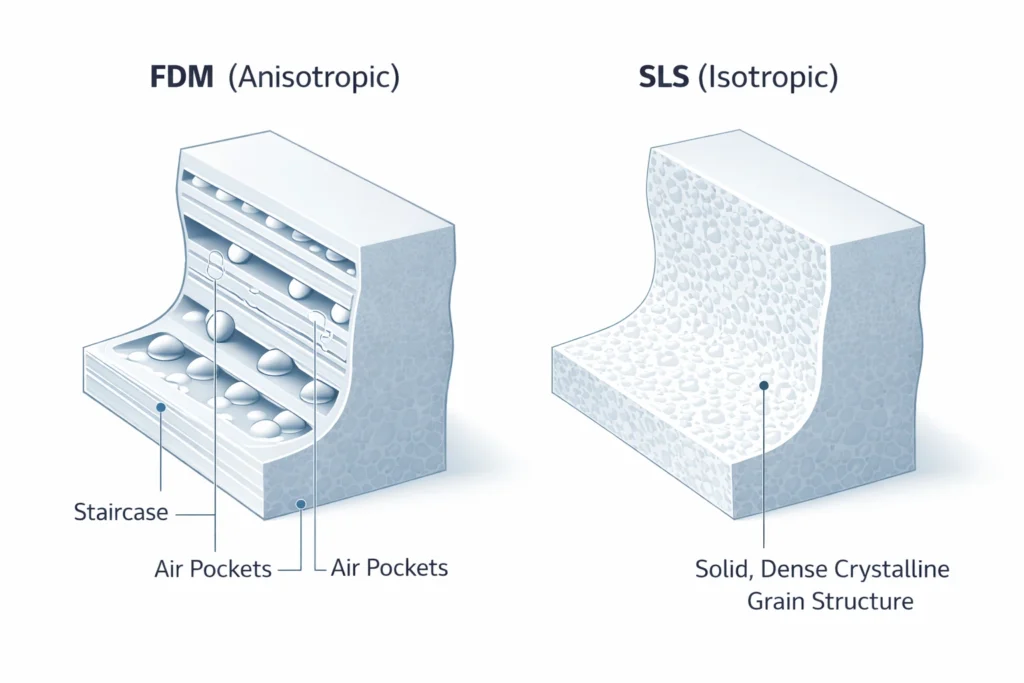

| Strength | Anisotropic (Weakest at layer lines) | Isotropic (Uniform strength in all axes) | SLS |

| Surface Finish | Visible layer lines; “staircase” effect | Matte, grainy, sugar-like texture | SLS |

| Supports | Required for overhangs >45° | Support-free (Powder self-supports) | SLS |

| Dimensional Accuracy | ± 0.5% (Lower limit ± 0.5 mm) | ± 0.3% (Lower limit ± 0.3 mm) | SLS |

| Typical Cost | Lowest ($200 to $5,000 for Pro-sumer) | Higher ($30,000+ for Industrial systems) | FDM |

The Verdict: If your priority is cost-efficiency and size, FDM Technology is the logical starting point. If your priority is mechanical reliability and geometric complexity, SLS Technology is the industrial requirement.

Core Differences That Matter

The material science behind SLS and FDM is fundamentally different. This dictates everything from part strength to final finish.

Material Performance & Mechanical Properties

The SLS process produces parts with superior isotropic mechanical properties.

- Isotropic Defined: A material is isotropic when it exhibits the same strength properties in all three axes (X, Y, and Z).

- SLS Strength: Sintering melts powder into a single, cohesive mass, creating nearly perfect isotropic parts. An SLS Nylon 12 part behaves like an injection-molded part under stress.

- FDM Weakness: FDM builds parts layer by layer. The bond between layers (the Z-axis) is inherently weak. FDM parts are anisotropic and often fail at these layer lines when under tension.

Heat Resistance & Dimensional Stability

SLS materials maintain dimensional integrity at higher temperatures, making them suitable for demanding engineering applications.

- SLS Performance: Nylon 12 is a robust engineering plastic. It offers a high heat deflection temperature (HDT), often around 175°C (347°F). This makes it viable for under-the-hood automotive parts or production tooling.

- FDM Limitations: Standard FDM materials like PLA deform at very low temperatures (around 60°C). Even stronger materials like ABS and PETG fall short of Nylon’s thermal resistance, limiting their use in high-heat environments.

Surface Finish & Feature Resolution

SLS delivers a professional, uniform surface finish that minimizes post-processing effort.

- SLS Finish: SLS parts have a consistent matte, slightly grainy texture. This finish is easy to dye or coat. Feature resolution is high, allowing for crisp details down to 0.2 mm.

- FDM Finish: FDM parts are defined by visible layer lines. The finish is coarse and often requires extensive sanding, filling, or vapor smoothing to achieve a professional aesthetic.

Material Variety, Colors, and Availability

FDM offers an unparalleled selection of material types and colors for visual applications.

- FDM Variety: The market is saturated with FDM filaments, including PLA, ABS, PETG, TPU (flexible), Nylon, and advanced composites like Carbon Fiber or Wood-Fill. Colors are limitless.

- SLS Limitations: SLS materials are primarily limited to Polyamides (Nylon PA11 and PA12), some PEEK, and specialized TPU. You are usually restricted to natural grey or white parts that require post-print dyeing for color.

Design Freedom & Geometric Capabilities

The geometric limits of your design are dictated by how each machine manages gravity and overhangs during the printing process.

Support-Free Printing vs Support-Dependent Designs

The most significant workflow advantage of SLS is its self-supporting nature.

- SLS Support-Free: During a print, the part is completely submerged in a bed of unsintered powder. This powder acts as a natural scaffold, allowing for limitless overhangs and steep angles without any additional support structures.

- FDM Scaffolding: FDM cannot print in thin air. Any feature with an angle greater than 45 degrees requires a printed support “scaffold.”

- The Impact: Removing FDM supports is labor-intensive and inevitably leaves visible scars or pockmarks on the part surface. SLS parts emerge clean, requiring only a pressurized air blast to remove excess powder.

Internal Channels, Lattices, and Complex Assemblies

For advanced engineering, SLS is the only viable choice for high-complexity geometries.

- Internal Channels: Because SLS requires no internal supports, you can design conformal cooling channels or complex fluid paths that are impossible to reach or clean in an FDM part.

- Lattice Structures: SLS excels at printing high-density lattices for light weighting or shock absorption. In FDM, the support material would get trapped inside the lattice, making it impossible to remove.

- Consolidated Assemblies: You can print pre-assembled, interlocking parts (like a captive gear or a chain) in a single SLS build, a feat FDM technology struggles to replicate without significant assembly gaps.

Build Volume: Maximum Part Size and Scale

While SLS wins on complexity, FDM is the undisputed leader in large-scale production.

- FDM Scale: Industrial FDM machines like those from BigRep or Modix offer build volumes exceeding 1,000mm x 1,000mm x 1,000mm. This allows for full-scale automotive panels or large furniture pieces in a single print.

- SLS Limits: Most professional SLS systems (such as the Formlabs Fuse series) are capped at roughly 165 x 165 x 300mm. Large-format industrial SLS exists but is exponentially more expensive and rarely exceeds 500mm in any axis.

Production Economics & ROI

Selecting between SLS and FDM is a financial decision based on unit volume and labor costs. While FDM has a lower entry cost, SLS offers a superior break-even point for batch manufacturing.

Per-Part Cost at Low, Medium, and High Volumes

The cost efficiency of each technology shifts dramatically as your production volume increases.

- Low Volume (1–5 Parts): FDM is the winner. For a single part, the setup time is minimal, and material costs are negligible. FDM is the most economical way to produce one-off prototypes.

- Medium to High Volume (20–200+ Parts): SLS is the winner. Because SLS allows for 3D nesting (stacking parts vertically and horizontally in the build chamber), you can print dozens of parts in a single run.

- Efficiency Shift: While an FDM printer’s cost-per-part remains relatively flat, the SLS cost-per-part drops significantly as you fill the build volume, eventually becoming cheaper than FDM for small-batch production.

Material Utilization, Waste, and Nesting Efficiency

The way each technology uses raw material dictates its long-term sustainability and waste profile.

- Nesting Efficiency: In SLS, “Packing Density” refers to how many parts you can fit into the powder bed. A high packing density maximizes the ROI of every print cycle.

- Powder Recyclability: SLS is highly efficient; 50% to 80% of the unsintered powder from a print can be reclaimed, mixed with fresh powder, and reused for the next build.

- FDM Waste: FDM waste primarily comes from support structures. For complex parts, you may waste 20% or more of your filament on “throwaway” plastic scaffolds that cannot be recycled.

Total Cost of Ownership: Equipment, Maintenance, and Operation

The “sticker price” of the printer is only one part of the financial equation.

- The FDM Investment: A professional-grade FDM setup (e.g., UltiMaker or Bambu Lab) typically costs between $1,000 and $5,000. Maintenance is simple, and utilities are standard.

- The SLS Ecosystem: A functional SLS setup (e.g., Formlabs Fuse) requires an ecosystem including the printer, a powder recovery station, and a cleaning blast cabinet. This typically costs between $30,000 and $100,000.

- Labor & Facility: SLS requires dedicated space, specialized power, and more intensive safety/PPE protocols than FDM, significantly increasing the initial capital expenditure (CAPEX).

Speed, Throughput & Scalability

In 3D printing, “speed” is measured in two ways: how fast you get one part and how many parts you get per week.

Prototype Turnaround Time

For rapid, single-item iterations, FDM is the fastest technology on the market.

- Zero Warm-up: Most professional FDM printers reach operating temperature in under 5 minutes.

- Print Speed: A simple hand-held prototype can be completed in 2 to 6 hours.

- Immediate Access: Once the print finishes, you can remove the part immediately. Even with support removal, a designer can hold a physical FDM prototype the same morning it was designed.

Batch Production & Manufacturing Scalability

When moving from one prototype to fifty functional units, SLS is significantly more efficient.

- The Height Factor: SLS print time is determined primarily by the total height of the parts in the chamber, not the quantity.

- Massive Throughput: Printing 50 brackets in an SLS chamber takes roughly the same amount of time as printing one bracket of the same height. The laser scans each layer rapidly, regardless of how many parts are nested on that layer.

- FDM Scaling Issues: In FDM, every additional part added to the build plate adds linear time. Printing 50 parts takes nearly 50 times longer than printing one, making it a poor choice for scaling production.

- Cooling Cycles: Note that SLS requires a cool-down period (often equal to the print time) before parts can be extracted. While this delays a single part, the total volume of parts per 24 hours remains much higher than FDM.

Accuracy, Tolerances & Post-Processing

Precision and the labor required to reach a “finished” state are the primary drivers of long-term operational costs. SLS offers higher precision, while FDM varies significantly based on calibration.

Dimensional Accuracy and Repeatability

SLS provides superior dimensional stability, especially for complex, organic geometries.

- SLS Tolerances: Industrial SLS systems typically achieve a dimensional accuracy of ±0.3% (with a lower limit of ±0.3 mm). Because the parts are encased in a temperature-controlled powder bed, they experience less thermal warping than FDM.

- FDM Tolerances: Professional FDM printers generally achieve ±0.5% (with a lower limit of ±0.5 mm). However, FDM accuracy is highly dependent on part orientation and material shrinkage (e.g., ABS plastic shrinks more than PLA).

- Repeatability: SLS is the winner for consistency. A batch of 100 parts in an SLS chamber will have tighter tolerance clusters than 100 parts produced across multiple FDM build plates.

Post-Processing Requirements and Finishing Effort

The “hidden labor” of 3D printing often occurs after the machine stops running.

- FDM Manual Labor: The primary bottleneck for FDM is support removal. This is a manual process that requires pliers, picks, and sanding. It is time-consuming and risks damaging delicate features.

- SLS Depowdering: SLS parts require “excavation” from the powder block. While this can be automated using dedicated bead-blasting or vibrating stations, it is a messy process that requires a controlled environment to manage fine dust.

- Surface Enhancement: Both technologies support Vapor Smoothing. This chemical process melts the outer “skin” of the part to create a glossy, injection-molded look and can make FDM parts water-tight or SLS parts easier to clean.

- Dyeing: SLS parts (typically white or grey) are highly porous and ideal for immersion dyeing, allowing for deep, permanent color saturation that won’t flake off like paint.

Real-World Industrial Use Cases

Choosing between SLS and FDM often comes down to the specific mechanical environment the part must survive. Below are the industry-standard applications for each.

When SLS is the Better Choice

SLS is the primary choice for high-performance engineering and end-use production where part failure is not an option.

- Living Hinges: Due to the high fatigue resistance of Nylon 12, SLS is the only 3D process capable of producing functional living hinges that can cycle thousands of times without snapping.

- Complex Ductwork: SLS is ideal for HVAC and aerospace ducting with complex internal geometries and thin walls that require no internal supports.

- Load-Bearing Brackets: Because SLS parts are isotropic, they can handle multi-directional stress, making them safe for structural mounts and industrial brackets.

- Medical Orthotics: The ability to print custom-fit, biocompatible (PA12) orthotics and prosthetics with complex lattice structures makes SLS a staple in the medical device industry.

When FDM is the Better Choice

FDM excels in rapid iteration and environments requiring specialized, high-performance thermoplastics.

- Concept Models: When you need a physical “hand-held” model to verify ergonomics or scale at the lowest possible cost, FDM is unbeatable.

- Simple Jigs & Fixtures: For factory floor aids, such as drill guides or assembly nests with simple geometries, FDM provides a fast, “good-enough” solution.

- Aerospace & High-Temp Filaments: FDM has a unique advantage in its ability to print “Super Polymers” like PEEK, PEKK, and ULTEM™. These materials are used in aerospace for their extreme heat resistance and flame-retardant properties, which current SLS powders cannot match.

- Massive Visual Mockups: For architectural models or full-scale automotive body panels, the massive build volume of industrial FDM machines is the only practical solution.

Limitations & Risk Factors

Every manufacturing process has failure thresholds. Understanding these risks is essential for maintaining production uptime and ensuring operator safety.

Common Failure Modes and Design Constraints

Even with optimized settings, SLS and FDM are susceptible to specific thermal and mechanical failures.

- FDM Warping and Lifting: This is the most common FDM failure. As thermoplastics cool, they contract. If the bed adhesion is insufficient or the chamber temperature fluctuates, the corners of the part will curl or lift off the build plate, ruining the dimensional accuracy of the base.

- SLS Shrinkage and Thermal Drift: While SLS avoids the “lifting” seen in FDM, it faces non-uniform shrinkage. If parts are not cooled slowly within the powder “cake,” they can warp. Large, flat surfaces in SLS are particularly prone to “bowing” due to thermal gradients within the build chamber.

- FDM Delamination: Under mechanical load, FDM parts often fail through layer separation. If the extrusion temperature is too low, the layers do not fuse properly, causing the part to split like wood grain.

Operational Risks: Safety, Ventilation, and Maintenance

The environmental requirements for these machines differ significantly, impacting where you can safely install them.

- SLS Powder Risks: SLS utilizes fine polymer powders (Nylon 11, Nylon 12) (50–100 microns). These pose a respiratory hazard and, in certain concentrations, an explosion risk (combustible dust). Operators must use HEPA-filtered vacuums, wear N95 masks, and operate in a dedicated “grey room” environment.

- FDM VOC Emissions: Printing with materials like ABS or ASA releases Volatile Organic Compounds (VOCs) and Ultra-Fine Particles (UFPs). Without proper HEPA and carbon filtration, these emissions can cause respiratory irritation in office environments.

- Maintenance Overhead: FDM requires frequent nozzle cleaning and bed leveling. SLS maintenance is more complex, involving the cleaning of optical lenses, laser windows, and powder delivery seals; failure to maintain these leads to immediate and expensive print failures.

Final Selection Guide (The actionable takeaway)

To finalize your decision, use the following checklists. These criteria represent the “tipping points” where one technology becomes objectively more profitable and functional than the other.

Choose SLS If These Conditions Apply

Selective Laser Sintering is your best path when quality and volume outweigh the initial machine cost.

- Batch Production: You need to produce 20 to 200+ parts in a single unattended build cycle.

- Complex Geometry: Your design includes internal channels, lattices, or interlocking assemblies.

- Mechanical Isotropy: The part will face stress from multiple directions and cannot have a “weak axis.”

- Support-Free Requirements: You want to avoid the labor and surface scarring associated with manual support removal.

- Functional End-Use: The part must be airtight, watertight, or chemically resistant (e.g., fuel tanks or manifolds).

Choose FDM If These Conditions Apply

Fused Deposition Modeling is your best path for rapid visual feedback and specialized material needs.

- Strict Budget: You need a functional 3D printing setup for under $1,000 to $5,000.

- Large Scale: You need to print single components larger than 300mm to 500mm in any dimension.

- Material Specificity: You require a specific color, high-temp PEEK/ULTEM, or a flexible TPU filament.

- Office Compatibility: You need a “plug-and-play” machine that can sit on a desk without heavy dust-management infrastructure.

- Rapid One-Offs: You need a single physical model in hand within 3 to 5 hours of finishing the CAD file.

Frequently Asked Questions

Is SLS stronger than FDM?

Yes. SLS parts feature isotropic molecular bonding, meaning they have uniform strength in all directions. Unlike FDM, which is weak between layers, SLS sintered parts behave like solid, injection-molded plastic.

Can I use an SLS printer at home?

Rarely. SLS requires specialized 220V power, industrial ventilation, and strict safety gear to manage combustible dust. Most home environments lack the explosion-proof vacuum systems and “grey room” infrastructure necessary for safe operation.

Which technology offers better value for money?

It depends entirely on production volume. FDM is the most cost-effective for one-off prototypes, whereas SLS provides a better ROI for small-batch manufacturing due to its ability to print dozens of parts simultaneously via nesting.