ABS Plastic Injection Molding: Process Control, Defects, and Material Decisions

ABS (Acrylonitrile Butadiene Styrene) is the industry standard for components requiring high impact strength, dimensional stability, and a premium surface finish.

Successful high-volume production depends on rigorous moisture control and precise gate geometry to prevent structural failure.

This guide provides the technical thresholds, processing parameters, and troubleshooting protocols required for professional-grade injection molding.

Is ABS Suitable for Injection Molding

Before investing in tooling, evaluate if ABS aligns with your part’s environment and mechanical requirements. Its amorphous structure ensures predictable linear shrinkage, making it one of the most reliable resins for high-precision components.

Why ABS Is Commonly Used in Injection Molded Parts

ABS dominates the market because it balances cost with high-performance physical properties:

- Exceptional Impact Toughness: The butadiene component provides superior energy absorption, preventing brittle failure even at low temperatures.

- Dimensional Stability: Low, uniform shrinkage rates (0.4%−0.7%) allow for tight tolerances in complex geometries.

- Superior Surface Finish: ABS naturally accepts high-gloss polishing, textures, painting, and metal electroplating.

- Rigidity and Strength: The acrylonitrile and styrene components provide the structural stiffness required for load-bearing housings.

- Predictable Processing: Its wide “processing window” reduces scrap rates during startup and long production runs.

When ABS Injection Molding Is a Poor Choice

Despite its versatility, ABS will fail in specific environments. Avoid this material if your application meets the following criteria:

⚠️ WARNING: MATERIAL LIMITATIONS

- Outdoor/UV Exposure: Standard ABS degrades rapidly under sunlight, leading to yellowing, chalking, and severe loss of impact strength.

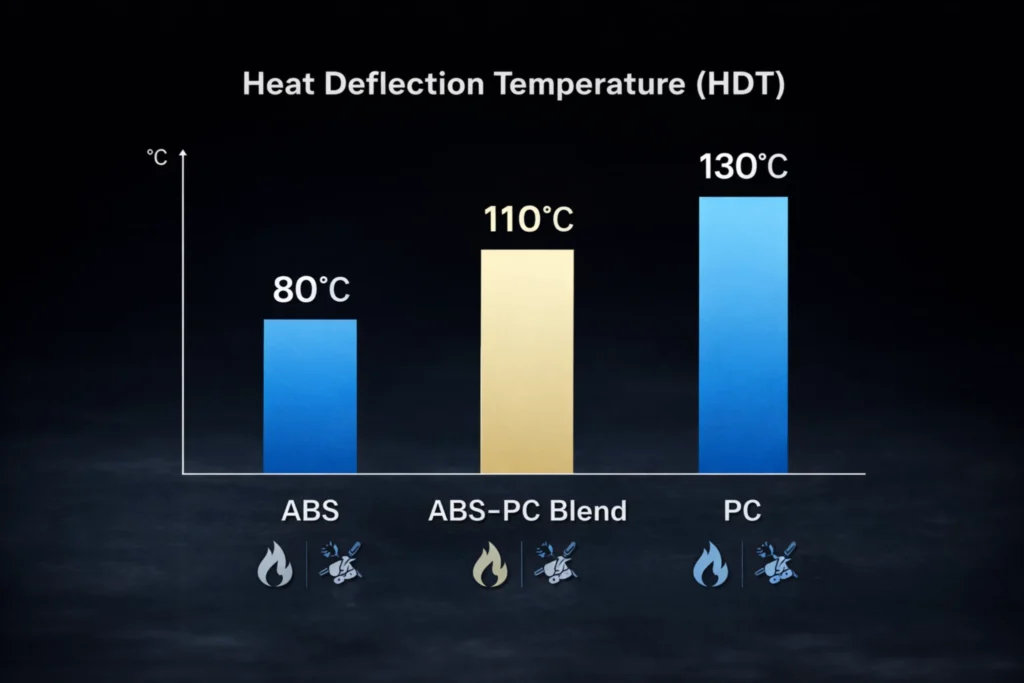

- High-Heat Environments: Part integrity fails as temperatures approach the Heat Deflection Temperature (HDT) of 80°C (176°F).

- Chemical Sensitivity: ABS dissolves or cracks when exposed to acetone, esters, ketones, and strong oxidizing agents.

- High-Friction Applications: Poor wear resistance makes it unsuitable for gears or sliding mechanisms without specialized additives.

ABS Material Grades and Blends

Selecting the correct ABS “flavor” is critical. Small variations in the monomer ratio, Acrylonitrile, Butadiene, and Styrene drastically alter the resin’s flow and end-use durability.

Injection-Grade vs General-Purpose ABS

Standard ABS is often too viscous for complex molds. Injection-grade resins are engineered with a higher Melt Flow Index (MFI) to ensure the melt reaches thin-walled sections without premature freezing.

| Feature | General-Purpose ABS | Injection-Grade ABS |

| Melt Flow Index (MFI) | 1–5 g/10 min (Low flow) | 10–40 g/10 min (High flow) |

| Impact Strength | Maximum; prioritized over flow. | Balanced to maintain toughness. |

| Application | Extrusion, thick-walled parts. | Thin walls, complex geometries. |

| Cycle Time | Slower due to cooling needs. | Faster; optimized for high-volume. |

ABS-PC Blends: Solving the Strength and Heat Gap

Standard ABS fails when continuous operating temperatures exceed 80°C. For automotive interiors or high-draw electronics, engineers utilize ABS-PC blends.

By alloying ABS with Polycarbonate, you increase the Heat Deflection Temperature (HDT) to 100°C–120°C. This blend combines the processability of ABS with the high-impact strength and thermal resistance of PC, making it the industry standard for crash-sensitive components.

Virgin vs Recycled ABS in Molding Applications

To reduce costs, manufacturers often mix recycled ABS “regrind” with virgin resin. However, ABS is sensitive to thermal degradation.

- The 20% Rule: Never exceed a 20% regrind-to-virgin ratio.

- The Risk: Every time ABS is melted, the butadiene rubber particles degrade. Exceeding 20% results in a sharp drop in notched izod impact strength and causes unpredictable color shifting, especially in lighter shades.

Key Processing Parameters for ABS Injection Molding

| Parameter | Technical Threshold |

| Drying Temperature | 80°C (175°F) |

| Drying Time | 3–4 Hours (Desiccant dryer preferred) |

| Melt Temperature | 230°C – 270°C |

| Mold Temperature | 50°C – 80°C |

| Injection Pressure | 70 – 120 MPa |

| Shrinkage Rate | 0.4% – 0.7% |

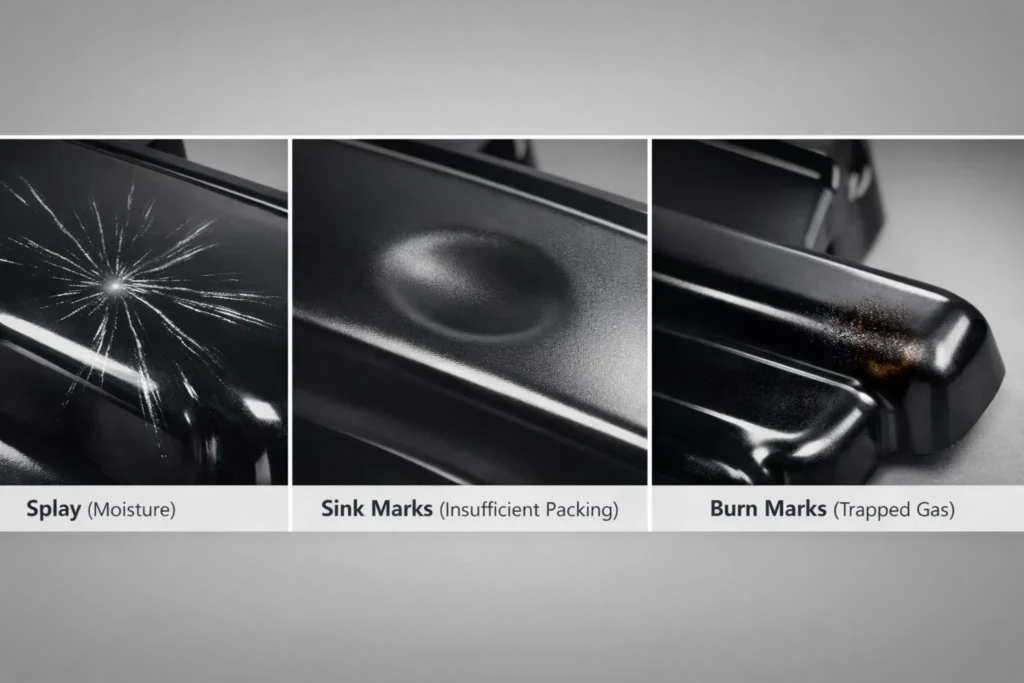

The Critical Role of Pre-Drying: Eliminating Splay and Surface Defects

ABS is hygroscopic, meaning it actively absorbs atmospheric moisture. Processing “wet” resin is the primary cause of cosmetic and structural failure.

- The Target: Moisture content must be below 0.02% before the material enters the hopper.

- The Risk: Excess moisture turns to steam in the barrel, causing Splay (Silver Streaks) tiny gas bubbles that scar the surface and weaken the molecular bond.

- Protocol: Dry pellets at 80°C for 3–4 hours. Avoid over-drying (>6 hours), which can cause oxidation and yellowing.

Melt Temperature, Mold Temperature, and Cooling Rate

Temperature control determines the balance between aesthetics and cycle time.

- Melt (230°C–270°C): High-heat ABS grades require the upper end of this range. Exceeding 280°C triggers thermal decomposition, releasing hazardous fumes and causing black specks.

- Mold (50°C–80°C): A hot mold improves surface gloss and weld line strength. Cooler molds reduce cycle time but increase internal stress and the risk of warpage.

Injection Pressure, Packing, and Shrinkage Control

ABS has a relatively high viscosity compared to Polypropylene.

- Filling: High injection pressures are necessary to fill thin sections.

- Packing: You must apply high packing pressure (typically 50-70% of injection pressure) to compensate for the 0.4%–0.7% shrinkage.

- The Goal: Proper packing prevents internal voids and ensures the part meets dimensional tolerances.

Common Defects in ABS Injection Molding

| Defect | Likely Primary Cause | Immediate Technical Solution |

| Splay (Silver Streaks) | Residual moisture in resin. | Dry resin at 80°C; target <0.02% moisture. |

| Sink Marks | Insufficient packing in thick zones. | Increase packing pressure/time; check gate seal. |

| Warpage | Non-uniform mold cooling. | Equalize core/cavity temps; extend cooling cycle. |

| Burn Marks | Trapped gas (diesel effect). | Reduce injection speed; clean/enlarge mold vents. |

| Weld Lines | Low melt temperature at flow front. | Increase melt/mold temp; move gate location. |

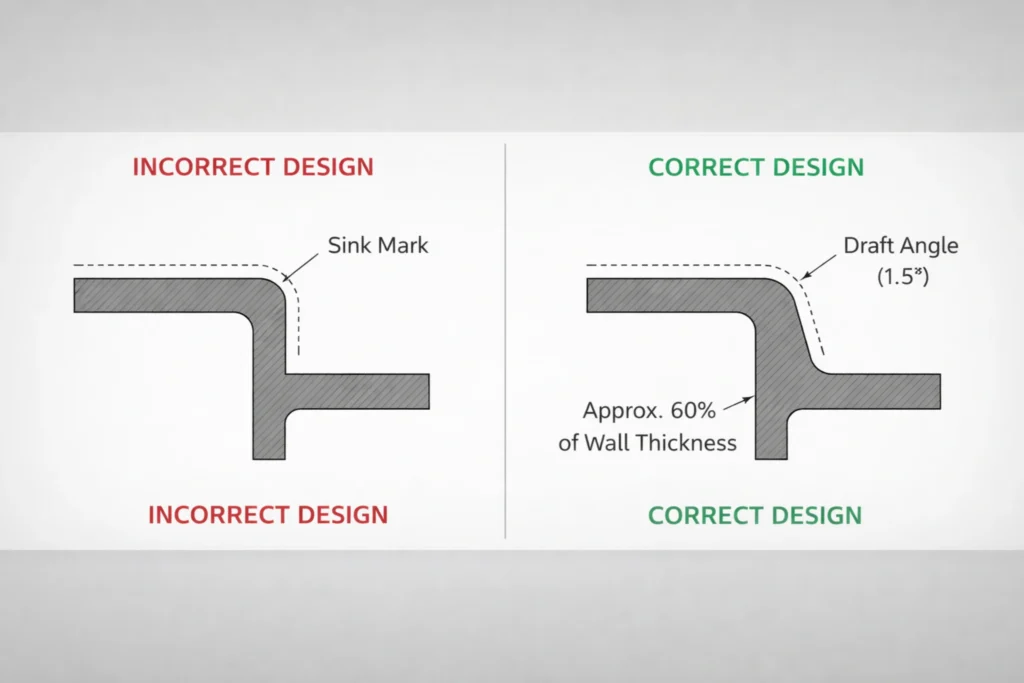

Structural Issues: Sink Marks, Warpage, and Weld Lines

Structural integrity is dictated by the relationship between geometry and pressure.

- Wall Thickness Rule: To avoid the majority of structural defects, maintain a uniform wall thickness between 1.5mm and 3.5mm.

- Sink Marks: If a wall is too thick, the core stays molten longer than the skin, pulling the surface inward. Limit rib thickness to 50–60% of the nominal wall thickness.

- Warpage: Caused by internal stresses. Ensure your Draft Angles (1.5°–2°) are sufficient to prevent the part from sticking and deforming during ejection.

Aesthetic Issues: Splay, Gloss, and Burn Marks

Cosmetic perfection in ABS is a function of “clean” processing and venting.

- Splay: Almost always caused by improper drying. If splay persists after drying, check for leaking nozzle heaters or excessive back pressure.

- Gloss Variation: Inconsistent surface shine usually indicates fluctuating mold temperatures. Maintain a steady 60°C–80°C to ensure consistent resin-to-steel contact.

- Burn Marks: If black or charred streaks appear at the end of a flow path, the air cannot escape. Reduce injection speed by 10% increments to allow gas to exit the vents.

Tooling and Mold Design Considerations for ABS

Successful ABS production starts with the mold. Because ABS is shear-sensitive and prone to gas entrapment, the tooling must prioritize efficient flow and aggressive venting.

Gate Design, Venting, and Wall Thickness Rules

Proper gate sizing is the difference between a high-yield run and constant part failure.

- Gate Selection: Use Tab or Edge gates for the majority of ABS parts. These gate types minimize shear heat and allow for easier manual or automated degating.

- The 50/60 Rule: To ensure effective packing and prevent premature freeze-off, size your gate at 50% to 60% of the nominal part thickness.

- Venting Requirements: ABS releases significant gas during injection. Design vents with a depth of 0.025mm to 0.05mm. Vents should be placed at the end of every flow path and near weld lines to prevent “dieseling” (burn marks).

- Wall Consistency: Maintain a thickness range of 1.5mm to 3.5mm. Abrupt transitions in thickness lead to internal stress and catastrophic warpage.

Mold Steel Selection and Surface Finish

The hardness and polishability of the mold steel directly impact the longevity and aesthetics of the ABS part.

- Steel Grade:

- P20 Steel: The standard choice for medium-volume production; offers excellent machinability and sufficient hardness.

- H13 Steel: Recommended for high-volume runs or reinforced ABS grades. It provides superior resistance to thermal fatigue and wear.

- Surface Finish: ABS is highly compatible with the SPI-A2 (High Gloss) standard. Its molecular structure allows it to replicate the mold surface with extreme fidelity. If a matte look is required, ABS also responds well to chemical etching (MT-textures) or bead blasting.

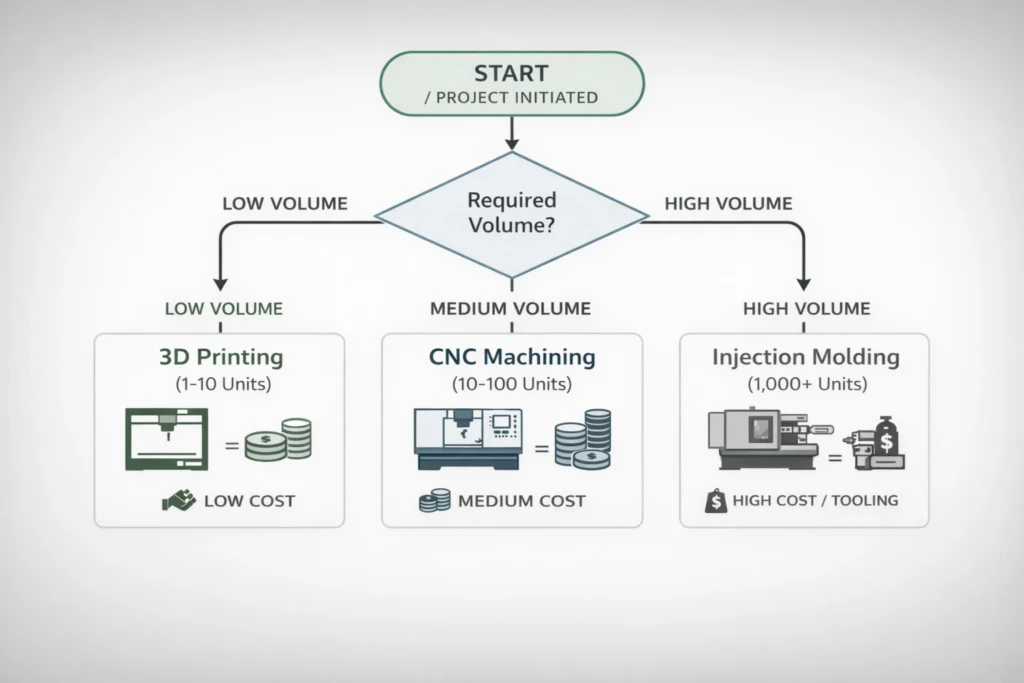

ABS Injection Molding vs Machining and 3D Printing

Selecting a manufacturing process depends on your production volume and budget. While ABS is compatible with multiple methods, the “break-even” point determines when to switch from prototyping to hard tooling.

Cost, Lead Time, and Volume Break-Even Analysis

Injection molding has high upfront costs due to mold fabrication but offers the lowest per-part cost at scale. Use this table to align your process with your volume:

| Feature | 3D Printing (FDM/SLA) | CNC Machining | Injection Molding |

| Optimal Volume | 1 – 10 units | 10 – 100 units | 1,000+ units |

| Setup Cost | Negligible | Moderate (Programming) | High (Tooling) |

| Lead Time | 1–3 Days | 3–10 Days | 4–10 Weeks |

| Material Strength | Lower (Layer adhesion) | High (Isotropic) | Maximum (Isotropic) |

| Unit Cost | Fixed/High | High | Very Low |

Choosing the Right Process for Part Geometry

Geometry often dictates the process regardless of volume.

- Design for Manufacturing (DFM): Injection molding requires Draft Angles of 0.5° to 2° on all vertical walls to allow part ejection. Machining ABS and 3D printing do not require drafts, making them better for straight-walled prototypes.

- Internal Cavities: 3D printing can create complex internal lattices that are impossible to mold.

- Surface Consistency: Molding is the only process that provides identical surface finish across thousands of parts without secondary manual labor.

Mechanical and Thermal Performance of Molded ABS

Impact Strength, Heat Resistance, and Creep

The defining characteristic of ABS is its notched Izod impact strength, typically ranging from 200 to 400 J/m. This resilience is due to the polybutadiene rubber particles dispersed within the rigid SAN matrix, which stop cracks from propagating.

- Heat Resistance: Standard ABS maintains structural integrity up to a Heat Deflection Temperature (HDT) of 80°C–90°C. Beyond this, the material softens rapidly.

- Creep Resistance: ABS exhibits excellent resistance to creep, the tendency of a solid material to move slowly or deform permanently under mechanical stresses. This makes it superior to Polypropylene for parts that must hold a screw or remain under tension.

Dimensional Stability and Long-Term Performance

Precision engineers favor ABS because it is dimensionally stable.

- Low Moisture Sensitivity: While it requires drying before molding, once a part is cured, it absorbs very little water (<0.7%), preventing the swelling or “growth” common in Nylon (PA 66).

- Load Bearing: Under constant load, ABS resists deformation. It does not “flow” over time, ensuring that snap-fits and enclosures remain tight throughout the product’s lifecycle.

- Predictable Shrinkage: Because it is amorphous, it shrinks uniformly in all directions. This allows for the production of high-tolerance parts that fit perfectly with other components in an assembly.

Applications of ABS Injection Molded Parts

Consumer Products, Housings, and Enclosures

In the consumer market, ABS is valued for its “premium” feel and vibrant colorability.

- Toys: LEGO bricks are the gold standard for ABS molding, utilizing the material’s dimensional stability for a perfect “clutch power” fit.

- Power Tools: Housings for drills and saws use ABS for its ability to absorb vibration and survive high-velocity drops.

- Electronics: Computer keyboards, remote controls, and laptop chassis rely on its rigidity and scratch resistance.

- Appliances: Vacuum cleaner bodies and kitchen mixer housings benefit from its glossy finish and chemical resistance to household cleaners.

Automotive and Industrial Component Use

The automotive industry utilizes ABS and ABS-PC blends to reduce vehicle weight without sacrificing passenger safety.

- Interior Trim: Dashboard panels, glove box assemblies, and pillar covers.

- Exterior Parts: Front grilles and mirror housings, often electroplated with chrome for a metallic finish.

- Functional Parts: Center console structural components and air vents that require high-precision movement.

For industrial use, the focus shifts to impact protection and environmental stability.

- Protective Cases: High-impact carrying cases for delicate instruments and equipment.

- Pipe Fittings: Used extensively in drain-waste-vent (DWV) piping systems due to its rigidity and ease of solvent welding.

- Housings: Protective enclosures for industrial sensors, wall outlets, and junction boxes.

Final Decision Checklist for ABS Injection Molding

Before committing to a production run, use this final technical audit to ensure your project is optimized for high-yield manufacturing and long-term part performance.

Design Readiness Checklist

Ensure your CAD data meets these five critical Design for Manufacturing (DFM) thresholds to prevent common molding failures:

- Draft Angles: Are all vertical walls drafted at 1.5° to 2°? Insufficient draft leads to drag marks and part deformation during ejection.

- Wall Thickness: Is the nominal wall between 1.5mm and 3.5mm? Ensure transitions are gradual to prevent internal stress.

- Corner Radii: Have you avoided sharp internal corners? Use a radius of at least 25% of the wall thickness to reduce stress concentration and improve melt flow.

- Rib Design: Are your supporting ribs thickness between 50% and 60% of the main wall? Anything thicker will cause visible sink marks.

- Gate Location: Is the gate positioned in the thickest section of the part? This ensures the melt flows from thick-to-thin, allowing for proper packing.

When to Switch to Nylon, PC, or Blends

If your application requirements exceed the physical limits of ABS, “pivot” to these specialized polymers:

- Need UV Resistance? → Switch to ASA: Acrylonitrile Styrene Acrylate (ASA) is the “weatherable” cousin of ABS. It offers identical mechanical properties but does not yellow or become brittle in direct sunlight.

- Need Extreme Heat? → Switch to Polycarbonate (PC): If operating temperatures exceed 90°C, PC provides the necessary thermal stability and superior clarity.

- Need Chemical Resistance? → Switch to Nylon (PA) injection molding: If the part will be exposed to oils, fuels, or harsh solvents, Nylon offers the chemical resilience that ABS lacks.

- Need Low Cost for Simple Shapes? → Switch to Polypropylene (PP): For non-structural, high-volume consumer goods where impact strength is secondary to cost.

FAQs

Why does ABS plastic require drying before injection molding?

ABS is hygroscopic, meaning it absorbs moisture from the air. If not dried at 80°C for 3–4 hours to a moisture level below 0.02%, that water turns into steam during processing. This results in splay (silver streaks) on the surface and significantly reduces the part’s structural impact strength.

What is the standard shrinkage rate for ABS injection molding?

ABS has a predictable linear shrinkage rate of 0.4% to 0.7%. Because it is an amorphous material, it shrinks uniformly in all directions, making it easier to hold tight tolerances compared to semi-crystalline plastics like Polypropylene or Nylon.

When should I use an ABS-PC blend instead of standard ABS?

You should pivot to an ABS-PC blend when your application requires higher heat resistance or superior impact strength. ABS-PC increases the Heat Deflection Temperature (HDT) to 100°C–120°C, whereas standard ABS begins to lose structural integrity at approximately 80°C.

How can I eliminate sink marks in my ABS molded parts?

Sink marks are typically caused by thick wall sections. To eliminate them, ensure your wall thickness is between 1.5mm and 3.5mm and that any internal ribs are only 50% to 60% of the thickness of the main wall. Additionally, increasing packing pressure and time can help compensate for shrinkage.

Can I use 100% recycled ABS for high-quality parts?

No. To maintain mechanical integrity and color consistency, follow the “20% Regrind Rule.” Exceeding 20% recycled content degrades the polybutadiene rubber particles, leading to a sharp decline in impact resistance and unpredictable surface finishes.