Can You Laser Cut Polycarbonate? (The Honest Truth & Best Alternatives)

You can laser cut polycarbonate, but you shouldn’t for most projects. It produces toxic hydrogen cyanide gas, poses a high fire risk, and results in charred, yellowed edges. Only laser cut sheets under 1.5mm. For thicker material, use CNC routing for clean results.

The Direct Answer: Can You Laser Cut It Safely?

Why “Can You” and “Should You” are two different things

Technically, a CO2 laser can penetrate polycarbonate, but the economic cost is high. The heat melts the polymer chain rather than vaporizing it. This creates permanent discoloration and a “gooey” edge that requires hours of manual sanding. You trade machine time for labor costs, usually resulting in a net loss.

The 1mm Exception: When thin films actually work

Thin films (0.1mm to 1mm) are the only exception. Because the material is thin, the laser passes through quickly. Heat does not linger long enough to cause the thermal runaway that chars thicker panels. If your sheet is over 2mm, stop; the quality drops exponentially.

The “Toxic Reality”: Hydrogen Cyanide and Machine Damage

Polycarbonate contains chlorine and carbon structures that, when burned, release Hydrogen Cyanide (HCN) and Carbon Monoxide. HCN is acutely toxic to humans and corrosive to your laser’s hardware. Without a high-capacity industrial fume extractor, you risk respiratory injury and permanent pitting of your motion rails.

The Science of Failure: Why Polycarbonate Rejects Laser Heat

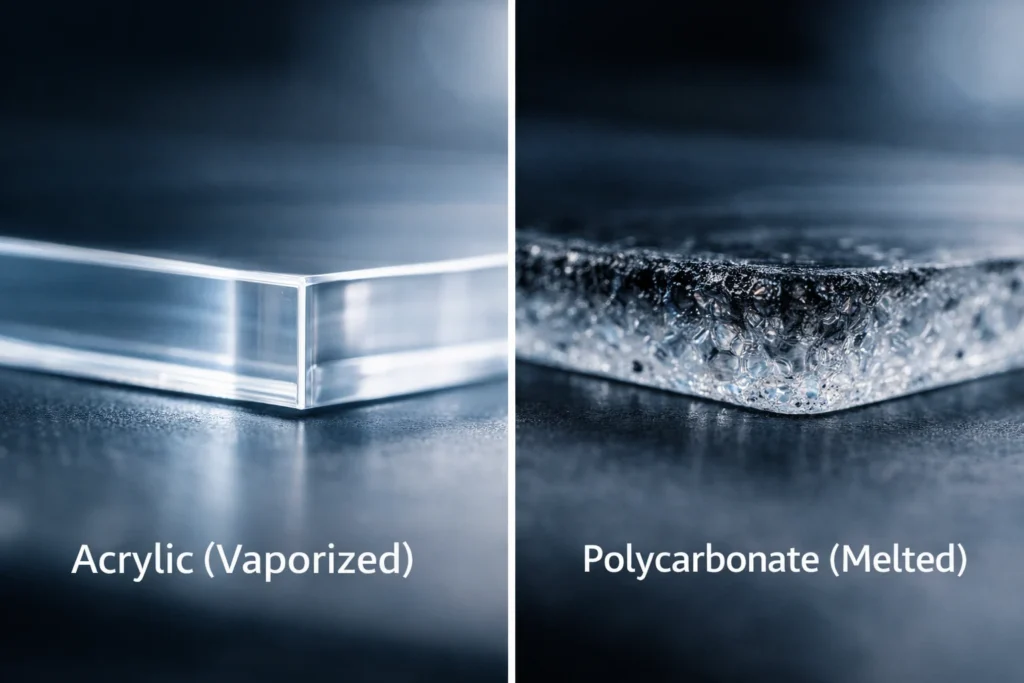

Polycarbonate vs. Acrylic: Why one vaporizes while the other melts

The fundamental failure lies in the material chemistry. Polycarbonate and Acrylic (PMMA) react to infrared energy in polar opposite ways:

- Acrylic (Vaporizes): The laser turns the solid directly into gas. This results in a polished, flame-clear edge with zero residue.

- Polycarbonate (Melts): It transitions into a viscous liquid state. Instead of disappearing, the molten plastic pool

The “Soot Factor”: How yellowing and charring ruin the aesthetic

Polycarbonate has a high carbon content. When the laser’s heat exceeds the material’s thermal threshold, it triggers carbonization. The laser essentially “burns” the plastic like coal rather than cutting it. This produces a fine black soot that chemically welds itself back onto the cut edge. This soot is not just a surface stain; it is embedded in the melt-zone and nearly impossible to clean.

Dimensional Distortion: Why your parts won’t fit after cutting

Polycarbonate is sensitive to Heat Affected Zones (HAZ). The intense localized temperature introduces internal thermal stress. As the part cools, it may warp or develop “crazing” (micro-cracks) along the edges. If you later clean these edges with alcohol or solvents, the part may shatter instantly due to this residual stress.

Common Laser Types: CO2, Fiber, and UV Results

Not all lasers interact with polymers the same way. Selecting the wrong wavelength can result in either zero cutting power or catastrophic machine failure.

| Laser Type | Material Interaction | Recommendation |

| CO2 (10.6μm) | High absorption; causes rapid melting and heavy charring. | Use only for thin films (<1.5mm). |

| Fiber (1.06μm) | Beam passes through transparent sheets without cutting. | Avoid. Back-reflections can destroy the laser source. |

| UV (355nm) | “Cold cutting” breaks molecular bonds without heat. | Best for precision and medical-grade thin films. |

Why standard 10.6μm CO2 lasers struggle

The 10.6μm wavelength is too “aggressive” for the chemical bonds of polycarbonate. The material absorbs this energy so rapidly that the Heat Affected Zone (HAZ) spreads laterally before the beam can pierce through. This causes the surrounding area to boil and yellow before the cut is even complete, resulting in the characteristic burnt-toast appearance and structural weakening.

Fiber Lasers: Why transparency is a barrier

Fiber lasers (typically 1.06μm) operate in a spectrum that clear polycarbonate does not recognize as a solid. The beam passes through the sheet like light through a window. This is not just ineffective- it is dangerous. The beam can hit the metal slats of your machine and reflect back into the laser optics, causing catastrophic hardware failure. Never attempt to cut clear polycarbonate with a Fiber laser.

UV Lasers: The only professional “Cold Cutting” solution for thin films

UV lasers (355nm) use photomods, or “cold ablation,” to break molecular bonds rather than using raw heat to melt them. This allows for incredibly intricate cuts on polycarbonate films with zero charring or soot. While UV lasers lack the power to cut thick structural panels, they are the industry standard for high-precision medical and electronic polycarbonate components where optical clarity is non-negotiable.

Safety & Machine Protection (The “Hidden” Costs)

Personal Safety: Why standard ventilation isn’t enough for HCN gases

Cutting polycarbonate releases Hydrogen Cyanide (HCN), a highly toxic gas. Standard charcoal or HEPA filters saturate almost instantly when exposed to these fumes, rendering them useless. For personal safety, you must use high-volume external venting that exhausts directly outside. Never rely on recirculating “smoke eaters” unless they are specifically rated for acid gases.

Machine Maintenance: How “sticky soot” destroys mirrors and lenses

The “sticky soot” produced by polycarbonate is not just messy; it is chemically aggressive.

- Optics: Soot coats mirrors and lenses, absorbing laser heat and causing cracked optics or permanent pitting.

- Mechanicals: Residue settles on rails and bearings, increasing friction and motor wear.

- The Bed: Sticky deposits clog honeycomb cells, reducing vacuum airflow and increasing future fire risks.

Action: If you must cut, perform a full optical cleaning immediately afterward to prevent permanent acid etching.

Fire Risks: Why polycarbonate is a “high-flare” material

While polycarbonate is technically self-extinguishing, it produces dense, oily smoke. This smoke creates a “canopy” that traps heat and can ignite residual debris or dust in your exhaust ducting. Never leave the machine unattended; a polycarbonate flare-up can quickly transition into a contained duct fire.

Best Alternatives to Laser Cutting (The “Pro” Choice)

If your project requires polycarbonate thicker than 1.5mm, abandon the laser. These mechanical methods provide superior results without the toxic risk or material ruin.

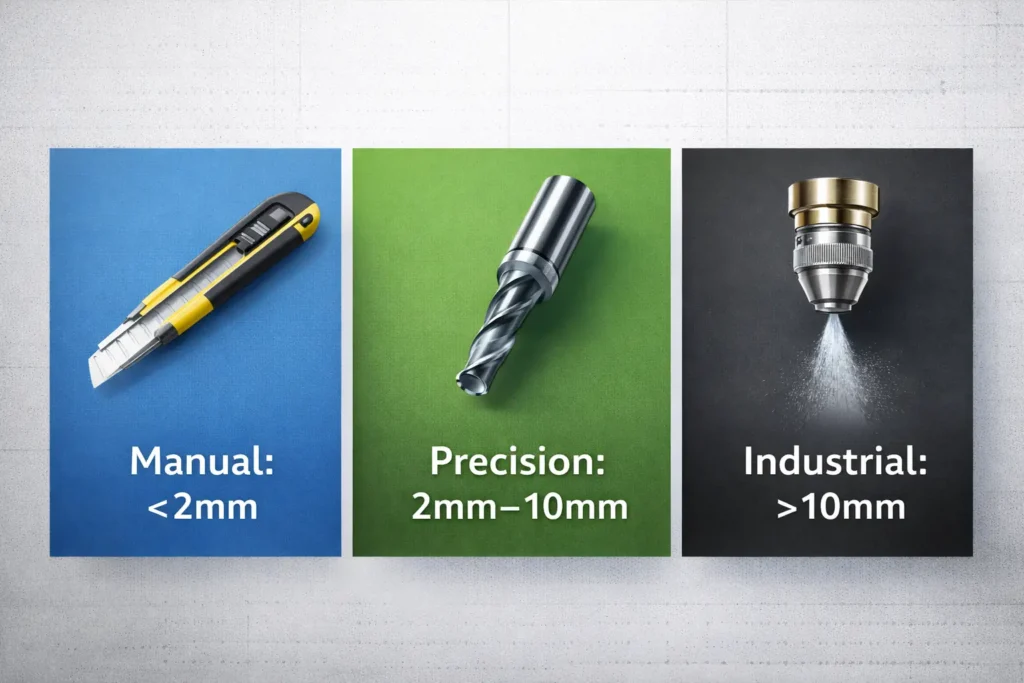

CNC Routing: Why this is the #1 choice for thick polycarbonate

For precision parts and complex geometries, CNC Routing is the undisputed winner. Because it uses a physical spinning bit, it removes material without heat. This results in flawless, clear edges and maintains the material’s structural integrity. It is the only way to achieve tight tolerances on thick panels.

Waterjet Cutting: Best for heat-sensitive and industrial parts

When working with sheets over 6mm, use Waterjet Cutting. By using a high-pressure stream of water and abrasive, this method eliminates the Heat Affected Zone (HAZ) entirely. There is zero yellowing, zero charring, and no risk of fire, making it ideal for industrial safety shields.

Scoring and Snapping: A low-cost method for straight lines

For simple, straight cuts, avoid expensive machinery. Use a carbide scoring tool or a heavy-duty utility knife. Score the sheet deeply (about 30% of the thickness) and snap it over a sharp edge. It is faster, safer, and cleaner than any laser for basic rectangular shapes.

Quick-Reference Guide: Material Selection Table

Choosing the right plastic prevents project failure. If your design requires a laser but needs more strength than acrylic, PETG is often the superior middle ground.

| Feature | Acrylic (PMMA) | Polycarbonate (PC) | PETG |

| Impact Resistance | Low (Brittle) | Extreme (Bulletproof) | High (Durable) |

| Laser Edge Quality | Flame-Polished | Charred/Yellow | Clean/Slight Burr |

| Ease of Cutting | Excellent | Poor (Over 1.5mm) | Good |

Value Add: Use Acrylic for aesthetics, Polycarbonate for high-impact industrial use, and PETG for a balance of laser-ability and toughness.

Final Verdict: When to Say “Yes” and When to Say “No”

The “Thickness Rule”: The 3mm cut-off point

- IF <1.5mm: Maybe. Proceed with high speed and low power to minimize charring.

- IF >1.5mm: No. The heat accumulation will result in melted, yellowed edges and toxic smoke. Use a CNC router instead.

Final checklist before you hit “Start” on your laser

Before you hit “Start,” confirm these three critical safety and quality conditions:

- Is your ventilation external? Never cut without direct-to-outside exhaust.

- Is edge quality a priority? If you need a clear finish, the laser will fail you.

- Is your air assist at max? High-pressure air is mandatory to blow away molten residue and prevent lens clouding.

FAQs

What is the best laser for cutting Polycarbonate?

9.3μm CO2 laser is the professional standard for cutting polycarbonate. Standard 10.6μm CO2 lasers are absorbed too aggressively, leading to excessive charring. For ultra-thin films (under 0.5mm) where optical clarity is critical, a UV laser (355nm) is the best choice as it uses “cold cutting” to break molecular bonds without melting the material.

What’s the best way to cut polycarbonate?

For sheets thicker than 1.5mm, CNC Routing is the best method because it produces clean, chip-free edges with zero heat damage or toxic fumes. For simple straight lines, the most cost-effective way is Scoring and Snapping using a utility knife. If you require industrial precision for thick panels (over 6mm), Waterjet Cutting is the superior cold-cutting alternative.

Are there different types of polycarbonate?

Yes. Beyond standard clear sheets (like Lexan or Makrolon), there are specialized grades:

- Machine Grade: Optimized for CNC machining with higher dimensional stability.

- UV-Stabilized: Coated to prevent yellowing in outdoor applications.

- Abrasion-Resistant: Features a hard coat to prevent surface scratches.

- Multiwall: A lightweight, cellular structure used for roofing (not suitable for laser cutting).

- Bullet-Resistant: Layered, thick panels designed for high-velocity impact.