UHMW vs PTFE: Differences in Strength, Friction, Wear & Industrial Applications

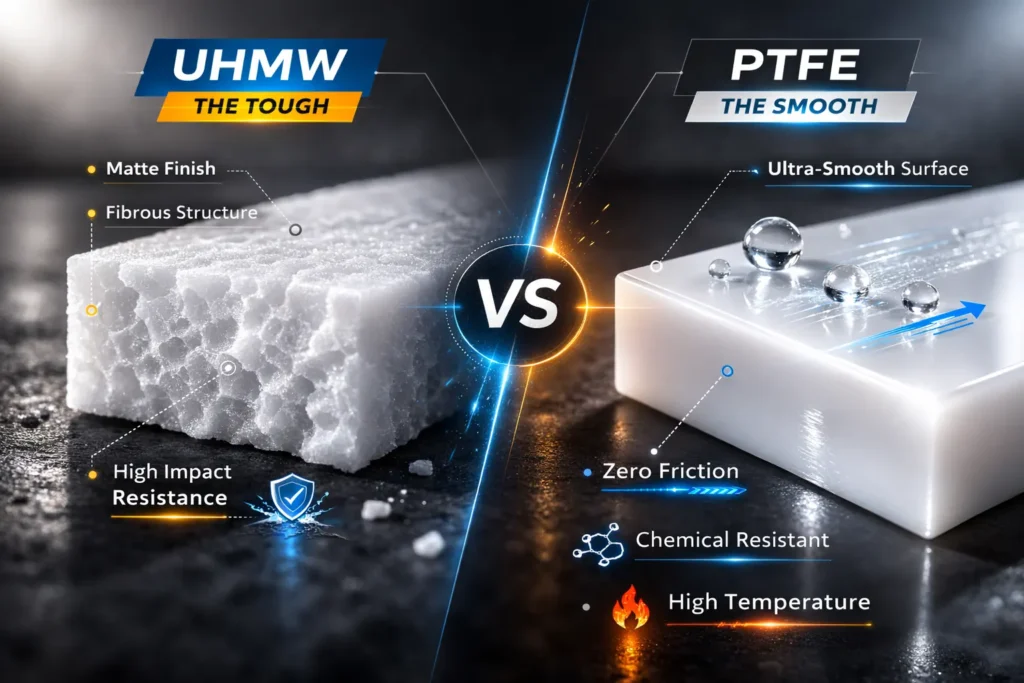

UHMW and PTFE are two high-performance engineering plastics used in low-friction, wear-resistant, and chemical-exposure environments. While both materials offer excellent durability and self-lubricating properties, they perform very differently under heat, load, and abrasive conditions.

UHMW (Ultra-High Molecular Weight Polyethylene) is known for extreme impact strength and abrasion resistance, whereas PTFE (Polytetrafluoroethylene) delivers unmatched chemical inertness and high-temperature stability up to 500°F.

Choosing between UHMW vs PTFE depends on your operating temperature, friction requirements, chemical exposure, and long-term cost considerations.

Quick Comparison Summary (Decision Snapshot)

| Property | UHMW (Polyethylene) | PTFE (Teflon) | Winner |

| Max Operating Temp | 180°F (82°C) | 500°F (260°C) | PTFE |

| Coefficient of Friction | 0.15 (Very Low) | 0.05 (Lowest Solid) | PTFE |

| Abrasion Resistance | Highest of all plastics | Low (prone to scarring) | UHMW |

| Impact Strength | Highest (No break) | Moderate | UHMW |

| Chemical Resistance | High (Except Oxidizers) | Universal (Inert) | PTFE |

| Relative Cost | $ (Economical) | $$$ (Premium) | UHMW |

When to Choose UHMW

- High-Impact zones: Use for dock fenders, wear strips, and chute liners.

- Abrasive environments: Use where sand, gravel, or grit will destroy other materials.

- Budget-critical builds: Use for high-volume parts under 180°F.

- Weight-sensitive applications: Use where high buoyancy or low density is required (0.93 g/cm³).

When to Choose PTFE

- High-Heat environments: Mandatory for applications exceeding 200°F.

- Extreme Chemical Exposure: Use for seals handling aggressive solvents or acids.

- Zero-Slip requirements: Use for precision bearings where “stick-slip” behavior must be eliminated.

- High-Frequency Insulation: Use for high-performance electrical connectors and RF components.

What Is UHMW (Ultra-High Molecular Weight Polyethylene)?

Molecular Structure & Composition

UHMW is defined by its extreme molecular weight, typically ranging from 3.5 to 7.5 million g/mol. Unlike standard high-density polyethylene (HDPE), these massive polymer chains are exceptionally long. This length causes the chains to entangle and overlap extensively, creating a structural “tangle” that transfers load more effectively. This unique architecture is the direct reason for its unmatched impact strength and resistance to fracturing under stress.

Mechanical Properties Overview

- Energy Absorption: UHMW has the highest impact strength of any thermoplastic (Nylon 11, Nylon 66, PC/ABS) currently made. It absorbs shock and vibration instead of cracking, making it ideal for heavy-duty mechanical stops.

- Self-Lubrication: The material naturally sheds surface tension. It mimics the behavior of a lubricated metal without requiring external grease or oil, preventing material buildup in industrial chutes.

- Zero Water Absorption: With a moisture absorption rate of <0.01%, UHMW remains dimensionally stable in submerged or high-humidity environments.

Chemical Resistance Profile

UHMW offers exceptional resistance to a broad spectrum of industrial chemicals. It is chemically inert to most strong alkalis, concentrated acids, and organic solvents. However, it is susceptible to strong oxidizing agents (such as fuming nitric acid) and certain aromatic/halogenated hydrocarbons at elevated temperatures.

- pH Range: Stable across nearly the entire 0–14 pH scale.

- Environmental Stress Cracking: Virtually immune to stress cracking, ensuring integrity in harsh wash-down environments.

- Limitation: Avoid contact with oxidizing acids which can degrade the molecular chains and cause surface embrittlement.

Common Industrial Applications

- Chute & Hopper Liners: Protects metal surfaces from abrasive bulk materials like grain, coal, or gravel.

- Star Wheels & Conveyor Guides: Provides high-speed, low-noise bottle and container handling in packaging lines.

- Dock Fenders: Absorbs the massive kinetic energy of ships docking in marine environments.

- Wear Strips: Acts as a sacrificial, low-friction surface for heavy-duty chain conveyors.

- Snowplow Blades: Offers a durable, non-marking edge that protects road surfaces and equipment.

What Is PTFE (Polytetrafluoroethylene)?

Molecular Structure & Composition

PTFE is a synthetic fluoropolymer composed entirely of carbon and fluorine atoms. Its structure consists of a long carbon backbone completely shielded by a “sheath” of fluorine atoms. This configuration creates the Carbon-Fluorine (C-F) bond, which is the strongest single bond in organic chemistry.

The extreme strength of these bonds makes the molecule nearly impenetrable to chemical attack and thermal degradation, resulting in the material’s signature chemical inertness and 500°F temperature stability.

Mechanical & Thermal Properties

PTFE is the industry standard for extreme temperature stability, maintaining its mechanical integrity from -450°F to +500°F (-268°C to +260°C). Unlike most plastics, it does not become brittle in cryogenic cold or melt into a liquid state at high heat.

- Cold Flow (Creep): A critical mechanical limitation. Under steady loads, PTFE will slowly deform (creep) over time.

- Low Surface Energy: Its extreme “slickness” prevents almost any substance from sticking to it, facilitating instant material release.

Chemical Inertness & Stability

PTFE is universally inert. The dense fluorine shield protects the carbon backbone from nearly all known chemicals, including “aqua regia” and hot fuming acids.

- Resistance: Total immunity to solvents, alcohols, and oxidizing agents.

- Exceptions: Only reactive with molten alkali metals (like sodium) and elemental fluorine at high temperatures and pressures.

- Sterilization: Withstands repeated autoclave and harsh chemical sterilization cycles without degrading.

Common Industrial Applications

- Chemical Processing: Gaskets, valve seats, and pump diaphragms handling highly corrosive fluids.

- Aerospace & Automotive: High-temperature fuel lines, wire insulation, and engine seals.

- Semiconductor Manufacturing: Ultra-pure fluid handling systems where zero contamination is mandatory.

- Medical Devices: Catheters and surgical implants due to its biocompatibility and low friction.

- High-End Cookware: Non-stick coatings for industrial and consumer food preparation.

Environmental & Regulatory Outlook (PFAS & “Forever Chemicals”)

While PTFE is a polymer of low concern (it is non-toxic and non-mobile), it is part of the broader PFAS family currently under global scrutiny.

- EU REACH & US EPA: Regulators are targeting the manufacturing process, specifically the surfactants used to make PTFE.

- Future-Proofing: For 2026 compliance, engineers are verifying that their PTFE supply is PFOA-free and monitoring potential “Polymer of Concern” legislation that could restrict certain fluoropolymer uses in non-essential applications.

UHMW vs PTFE: Side-by-Side Technical Comparison

The table below provides the direct numerical data required for engineering specifications. It contrasts the “Workhorse” (UHMW) against the “Specialist” (PTFE) to identify the superior material for your specific operating environment.

| Performance Metric | UHMW (Polyethylene) | PTFE (Teflon) | Engineering Implication |

| Density (g/cm³) | 0.93 – 0.94 | 2.1 – 2.3 | PTFE is 2x heavier; UHMW floats in water. |

| Max Service Temp | 180°F (82°C) | 500°F (260°C) | UHMW fails in heat; PTFE handles extreme ovens. |

| Min Service Temp | -450°F (-268°C) | -450°F (-268°C) | Both are Cryogenic-safe and impact-resistant. |

| Coeff. of Friction | 0.10 – 0.22 | 0.05 – 0.10 | PTFE is the world’s slickest solid material. |

| Tensile Strength | 3,000 – 5,800 psi | 2,500 – 4,500 psi | UHMW is stronger and resists “stretching” better. |

| Impact Strength | No Break | 3.5 ft-lb/in | UHMW is virtually unbreakable; PTFE is brittle. |

| Water Absorption | <0.01% | <0.01% | Both offer excellent dimensional stability. |

| Chemical Resistance | High (No Acids) | Universal (Inert) | PTFE resists all industrial solvents and acids. |

| Relative Cost | Economical ($) | Premium ($$$) | PTFE costs 3x–5x more per square foot. |

Friction & Sliding Performance Comparison

Stick-Slip Behavior

- The Problem: Many plastics “stick” when they start moving and “slip” once in motion, causing vibration and chatter.

- The PTFE Advantage: PTFE has nearly equal static and dynamic friction. It provides a seamless transition from rest to motion, making it mandatory for precision instruments, telescope mounts, and laboratory sliders.

- The UHMW Reality: While UHMW is highly self-lubricating, it exhibits a higher static “break-out” force. It is better suited for continuous high-speed conveyors rather than micro-adjustments.

Wear Resistance & Load-Bearing Performance

Abrasion Resistance

In abrasive environments, UHMW is the undisputed leader. According to the Sand Slurry Test, the industry standard for measuring volume loss UHMW registers a rating of 10 to 15, while PTFE often exceeds 100 (lower is better).

- The Fact: UHMW outwears carbon steel by a factor of 6 to 1 and outlasts PTFE by more than 8x in gritty conditions.

- The Implication: If your application involves sand, gravel, or sliding contact with rough surfaces (e.g., chute liners or conveyor wear strips), UHMW is the only viable choice. PTFE will scar and erode rapidly under these conditions.

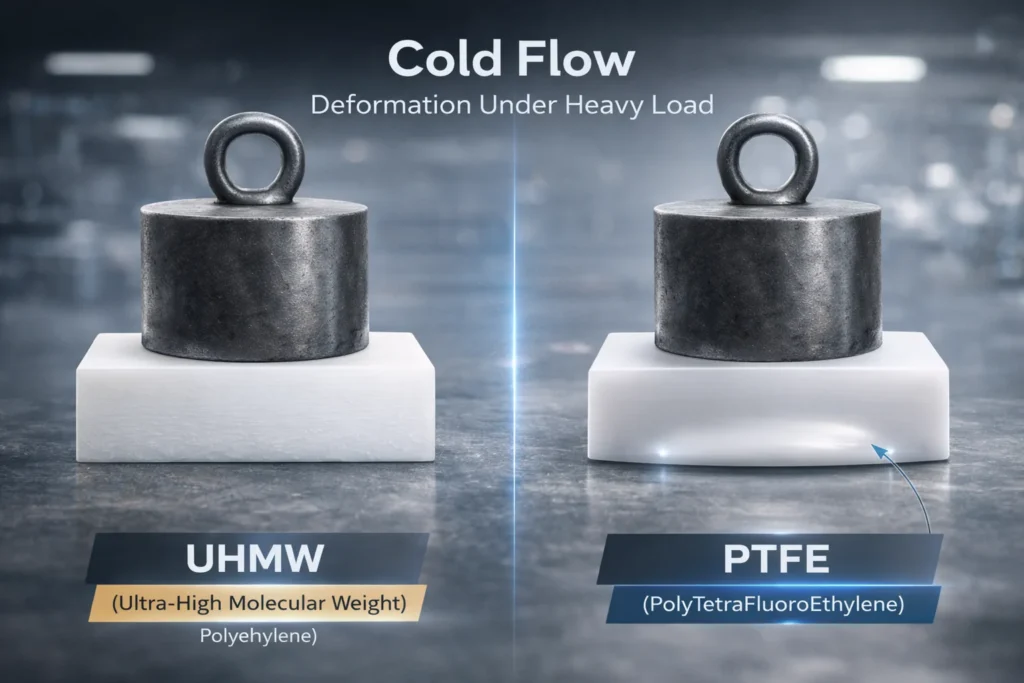

Long-Term Deformation (Creep)

Designers must account for “Cold Flow” when selecting materials for load-bearing seals or supports.

- PTFE Risk: PTFE is a soft, “ductile” plastic. Under a constant steady load, it will creep meaning it slowly deforms and “flows” away from the pressure point. This leads to seal failure and loss of dimensional tolerance.

- UHMW Stability: While not a structural metal, UHMW possesses a much higher compressive strength and resistance to permanent deformation.

- Pro Tip: If your part must hold a heavy load without changing shape over months or years, UHMW is significantly more reliable. If you must use PTFE for heat but need load-bearing capacity, you must use filled grades (e.g., Glass-filled or Carbon-filled PTFE).

Temperature & Chemical Resistance Analysis

Continuous Operating Temperature

Temperature is the primary “Go/No-Go” differentiator for these materials.

- PTFE: Excels in high-heat environments with a stable range up to 500°F (260°C). It does not melt but undergoes a gel transition at 621°F.

- UHMW: Strictly limited to low-temperature applications. It begins to lose structural integrity at 180°F (82°C) and reaches its melting point at 270°F (132°C).

- Key Decision: If your process temperature exceeds 200°F, PTFE is mandatory.

Performance in Extreme Cold

Both materials are industry leaders in cryogenic performance.

- Threshold: Both remain functional and retain impact resistance down to -450°F (-268°C).

- Behavior: Unlike most plastics that shatter in the cold, UHMW and PTFE remain relatively ductile. PTFE is slightly preferred for liquid nitrogen/oxygen seals due to its zero-porosity and chemical safety.

Resistance to Acids, Solvents & Alkalis

- PTFE (The “Universal” Resistant): Chemically inert to almost everything. It is untouched by sulfuric acid, nitric acid, and sodium hydroxide. Only molten alkali metals (e.g., sodium) or elemental fluorine can attack it.

- UHMW (The “Industrial” Resistant): Highly resistant to most common industrial chemicals, including salts and alkalis. However, it degrades when exposed to strong oxidizing acids and aromatic hydrocarbons.

- Risk Note: For concentrated acid pumping or storage, PTFE is the safer choice for long-term containment.

UV & Outdoor Stability

- PTFE: Inherently UV-stable. It does not yellow, embrittle, or degrade under direct sunlight. Ideal for outdoor gaskets and aerospace exteriors.

- UHMW: Standard white/natural UHMW will degrade and turn brittle under long-term UV exposure.

- Requirement: For outdoor use, you must specify “Black/UV-Stabilized” UHMW (Carbon-black filled) to achieve a multi-decade service life.

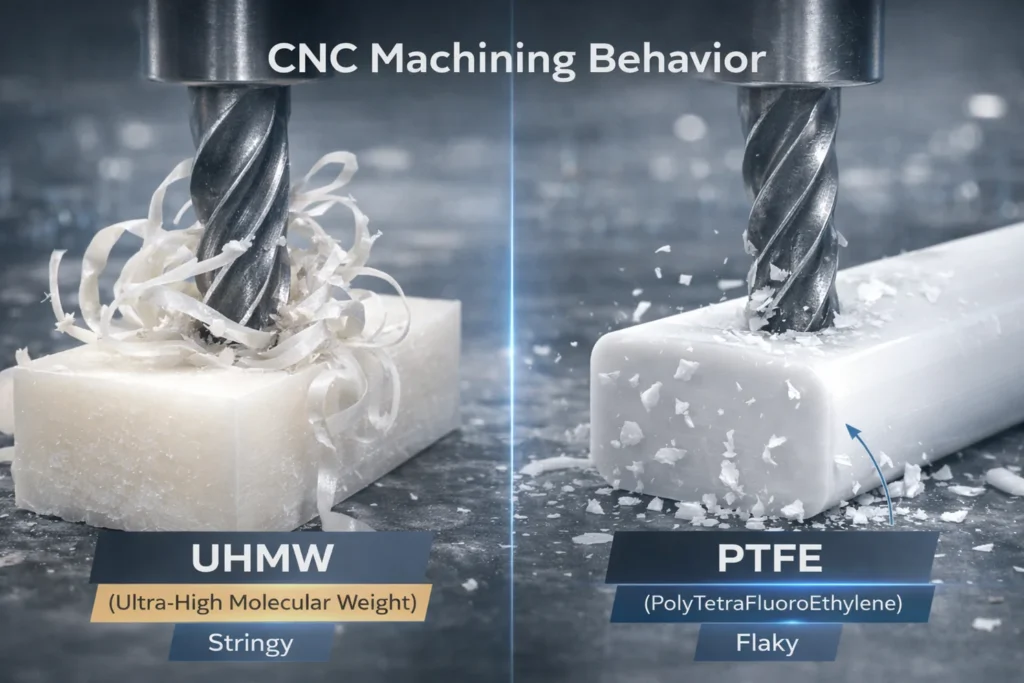

Machining & Fabrication Considerations

CNC Machining Behavior

- UHMW: Machines like soft wood. It is prone to burring and requires extremely sharp high-speed steel (HSS) or carbide tools with high clearance angles. Because it is flexible, parts can “push away” from the tool, making thin-walled sections difficult to hold to tight tolerances.

- PTFE: Known for “gumming” tools. It is very soft and generates heat quickly; if the tool is dull, the material will smear rather than cut. However, it is easier to achieve a high-precision finish than UHMW if proper cooling and sharp geometry are maintained.

Welding & Bonding Challenges

- Welding: UHMW can be hot-gas welded or butt-welded using specialized equipment. PTFE cannot be welded in the traditional sense because it does not melt into a liquid; it must be skived or mechanically fastened.

- Bonding: Both materials have near-zero surface energy, making standard adhesives useless.

- PTFE: Requires chemical etching (sodium naphthalene) to create a bondable surface.

- UHMW: Requires flame or plasma treatment and specialized epoxy primers for any level of adhesion.

Thermal Expansion Differences

- Fact: Both materials have high coefficients of thermal expansion (CLTE) compared to metals.

- PTFE: Experiences a volume change of ~1% at 66°F (19°C) due to a molecular phase transition. This “jump” makes holding micrometer-level tolerances impossible if the shop temperature isn’t strictly controlled.

- UHMW: Expands linearly but significantly. For long wear strips (over 10 feet), you must use slotted holes to allow the material to “grow” and “shrink” with ambient temperature changes to prevent buckling.

Surface Finish Capabilities

- PTFE: Can achieve a mirror-like, low-friction finish through precision turning. It is ideal for high-sealing surfaces in valves.

- UHMW: Usually results in a matte or slightly fuzzy finish due to the fibrous nature of its long molecular chains. It is functional for industrial wear but not intended for aesthetic or optical applications.

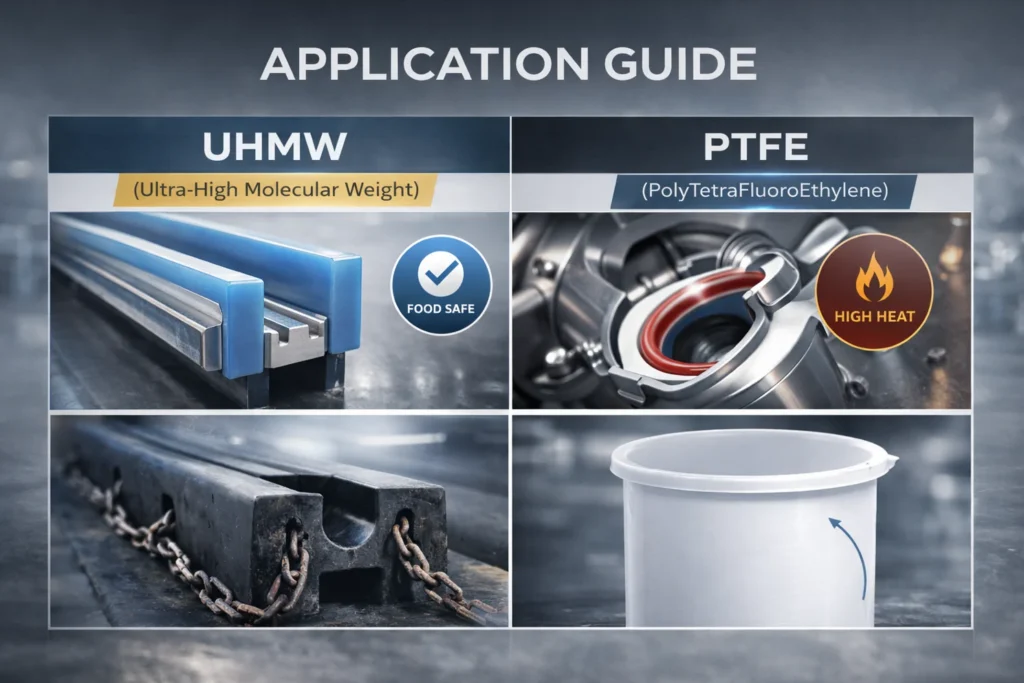

Industry-Specific Application Guide

Food Processing Equipment

Both materials are FDA and USDA compliant, but their roles differ by temperature.

- UHMW: Use for star wheels, deboning tables, and meat processing chutes where high impact and knife-cut resistance are required.

- PTFE: Required for industrial frying, baking seals, and high-heat filler valves where temperatures exceed 200°F.

Chemical Processing Plants

- UHMW: Effective for handling bulk dry chemicals and caustic wash-down environments in water treatment.

- PTFE: The standard for aggressive fluid handling. Used for pump diaphragms and lined piping because it remains unreactive to nearly every industrial acid and solvent.

Conveyor Systems

- UHMW: The industry standard for wear strips, chain guides, and rollers. Its high abrasion resistance ensures a long service life under constant mechanical friction.

- PTFE: Rarely used for conveyors due to high cost and low wear resistance, unless the system passes through a high-temperature curing oven.

Marine & Outdoor Applications

- UHMW: Used for dock fenders and boat trailer bunk liners. Note: You must use Black UV-stabilized grades to prevent embrittlement.

- PTFE: Used for specialized outdoor seals and gaskets in aerospace/marine instrumentation due to its inherent UV immunity and zero moisture absorption.

Medical & Pharmaceutical Use

- UHMW: Found in orthopedic implants (hip and knee joints) due to its extreme wear resistance and biocompatibility.

- PTFE: Used for catheters and sterile tubing because its “nothing sticks” surface prevents blood clots and protein buildup.

Consumer Electronics & Gaming (Mouse Skates & EV Components)

- Gaming: Virgin-grade PTFE is the choice for high-end “mouse skates” to achieve the lowest possible glide friction. UHMW is used in budget “long-life” skates for better durability on rougher mousepads.

- EV Components: PTFE provides superior thermal insulation for battery cell separators and high-heat wiring harnesses in electric vehicle motors.

Electrical Insulation Components

- PTFE: A superior dielectric material. Ideal for high-frequency insulation, RF connectors, and insulators in environments where heat would melt standard plastics.

- UHMW: Provides good insulation for low-voltage, high-impact mechanical housings, but lacks the high-frequency performance of PTFE.

Cost & Availability Comparison

The following table breaks down the financial implications of material selection. Use this to justify your procurement strategy based on life-cycle value rather than just initial price.

| Cost Factor | UHMW (Workhorse) | PTFE (Specialist) | Financial Impact |

| Raw Material Price | Economical ($) | Premium ($$$) | PTFE is 300%–500% more expensive per kg. |

| Machining Speed | Fast (High-feed) | Moderate (Slow-feed) | UHMW allows for higher throughput in CNC shops. |

| Fabrication Waste | Low (Recyclable) | High (Expensive Scrap) | PTFE scrap is difficult to reprocess, increasing net cost. |

| Replacement Cycle | Very Long (In Abrasion) | Short (In Abrasion) | UHMW reduces labor costs by minimizing downtime. |

| Maintenance Need | Near-Zero | Variable (Check for Creep) | PTFE requires monitoring for seal deformation. |

Advantages & Disadvantages

UHMW Pros & Cons

- PRO: Highest abrasion resistance of any thermoplastic; outlasts steel.

- PRO: High impact strength; will not crack or shatter under heavy loads.

- PRO: Most cost-effective solution for industrial wear components.

- CON: Low heat threshold (max 180°F); loses all structural integrity in ovens.

- CON: Poor UV resistance unless specified as Carbon-Black filled.

PTFE Pros & Cons

- PRO: Universal chemical resistance; survives the harshest industrial acids.

- PRO: Widest temperature range (-450°F to +500°F); stable where others melt.

- PRO: Absolute lowest friction; eliminates all stick-slip vibration.

- CON: Soft and prone to “creep”; deforms permanently under steady pressure.

- CON: High cost; often overkill for simple low-temp mechanical parts.

Frequently Asked Questions

Is UHMW more durable than PTFE?

In terms of abrasion and impact, yes. In terms of chemical and heat degradation, no.

Which has lower friction, UHMW or PTFE?

PTFE is the slickest solid material known; it has roughly half the friction of UHMW.

Which is better for food-safe applications?

Both are FDA compliant, but PTFE is preferred for high-heat cooking surfaces.

Can UHMW replace PTFE in bearings?

Only if the temperature is low and the load is high. PTFE “creeps” under load, so UHMW is actually better for heavy-duty, low-temp bushings.

Final Verdict

UHMW is the superior choice for mechanical durability and cost-efficiency. PTFE is the essential choice for extreme environments (Heat/Chemicals) where UHMW would physically fail.