ABS Plastic Recycling: Process, Challenges, and Industrial Use Cases

Recycling Acrylonitrile Butadiene Styrene (ABS) is a commercially viable strategy that recovers high-value engineering resin while reducing carbon emissions by up to 80% compared to virgin production. As a core pillar of the industrial circular economy, efficient ABS reprocessing diverts complex electronic waste from landfills and provides manufacturers with a cost-effective, high-performance alternative to primary polymers.

Is ABS Plastic Recyclable in Real-World Conditions

ABS is technically 100% recyclable, but its success depends entirely on the purity of the waste stream and the sophistication of the recovery facility. Unlike commodity plastics (PET or HDPE), ABS requires precise industrial handling to maintain its engineering properties.

The #7 Resin Identification Code (RIC) and How to Identify ABS

ABS falls under the “Other” category (Code #7), which often complicates manual sorting. Because Code #7 includes everything from bioplastics (PA 11) to multi-layer resins, professional recyclers use physical verification tests to confirm the material is truly ABS.

| Feature | Specification / Result |

| Recycling Symbol | #7 (Other) |

| Common Labelling | Often marked as >ABS< or >ABS+PC< on internal ribs of molded parts. |

| Sink/Float Test | Sinks in water. ABS has a density of 1.03–1.06 g/cm³, making it heavier than water (1.00 g/cm³). |

| Burn Test (Odor) | Emits a pungent, acrid, yet slightly sweet smell (due to the styrene component). |

| Burn Test (Visual) | Produce a yellow flame with significant amounts of sooty black smoke. |

Critical Note: ABS is frequently mislabeled or confused with Polycarbonate (PC) or High-Impact Polystyrene (HIPS). Using a mislabeled batch can contaminate an entire production run, leading to brittle parts and mechanical failure.

Thermoplastic Nature of ABS and What It Means for Recycling

ABS is a thermoplastic, meaning it responds to heat by softening rather than burning, allowing for multiple lifecycles.

- Reversible Transition: You can melt, mold, and re-solidify ABS repeatedly. Unlike “thermoset” plastics, the polymer chains do not form permanent cross-links that prevent remelting.

- Glass Transition Temperature (Tg): ABS becomes pliable at approximately 105°C (221°F). This relatively low Tg allows for energy-efficient reprocessing compared to high-heat polymers.

- Structural Integrity: Because it is an amorphous polymer, it shrinks less during cooling (0.4%–0.9%) than crystalline plastics (HDPE or Delrin), making recycled ABS (rABS) highly predictable for precision injection molding.

Why ABS Recycling Is Mostly Industrial, Not Household

You cannot typically recycle ABS through curbside “blue bin” programs. Most municipal recycling facilities (MRFs) use Near-Infrared (NIR) sensors to automate sorting. These sensors struggle to “see” or identify Black ABS, the most common color for electronics because the carbon black pigment absorbs the infrared light.

Consequently, ABS recycling is almost exclusively handled by industrial specialists who source material from electronic waste (e-waste) or automotive scrap where the waste stream is consistent and high-volume.

How ABS Plastic Is Recycled Step by Step

Industrial ABS recycling is a rigorous technical process designed to transform contaminated waste into high-purity resin that meets manufacturing tolerances.

Collection, Sorting, and Contamination Control

Efficiency in ABS recovery depends on isolating the polymer from complex assemblies (like laptops or car dashboards) quickly and accurately.

- Primary Disassembly: Technicians or automated systems remove non-plastic components, such as batteries, circuit boards, and wiring.

- Density Separation (Sink-Float): The shredded mix enters water tanks. ABS (density 1.03–1.06 g/cm³) sinks, while lighter plastics like Polypropylene or Polyethylene float, allowing for immediate mass separation.

- Electrostatic Sorting: This critical step separates ABS from HIPS (High-Impact Polystyrene). Since these two plastics have nearly identical densities, sensors use triboelectric charging to give particles a static charge; ABS and HIPS deflect in opposite directions toward charged plates.

- Optical Sorting: High-speed cameras identify and eject off-color flakes or remaining foreign polymers to ensure color consistency in the final batch.

Shredding, Washing, and Reprocessing Methods

Once sorted, the material undergoes mechanical refinement to prepare it for the extruder.

- Precision Shredding: Industrial grinders reduce the plastic into a uniform 10–15mm regrind. Consistent flake size is vital for even melting during extrusion.

- Abrasive Washing: Flakes are washed in a caustic solution to strip away industrial adhesives, labels, and residual oils.

- Mechanical De-dusting: A centrifugal process removes “fines” (plastic dust). Skipping this step causes “black spots” or carbonization in the final molded parts, which ruins aesthetic surfaces.

- Melt Filtration: During extrusion, the molten ABS passes through fine mesh screens (often as small as 100–200 microns) to capture any microscopic metal or wood particles that survived the wash.

Safety and Compliance: Navigating REACH and RoHS Regulations

For manufacturers, the biggest risk in using recycled ABS is “legacy contamination.” Older ABS often contains chemicals that are now illegal under REACH and RoHS standards.

“Red Flag” Additives in Recycled ABS:

- Brominated Flame Retardants (BFRs): Commonly found in ABS from pre-2006 electronics. These are often banned (e.g., OctaBDE) due to toxicity.

- Heavy Metals (Lead & Cadmium): Used as pigments or stabilizers in older automotive parts.

- Phthalates: Often found in secondary coatings or gaskets attached to ABS housings.

Manufacturer Advisory: Always demand a Certificate of Analysis (CoA) and RoHS compliance documentation from your recycler. If your source material is pre-2006 e-waste, professional laboratory testing for Deca-BDE is mandatory to ensure legal market entry in the EU and North America.

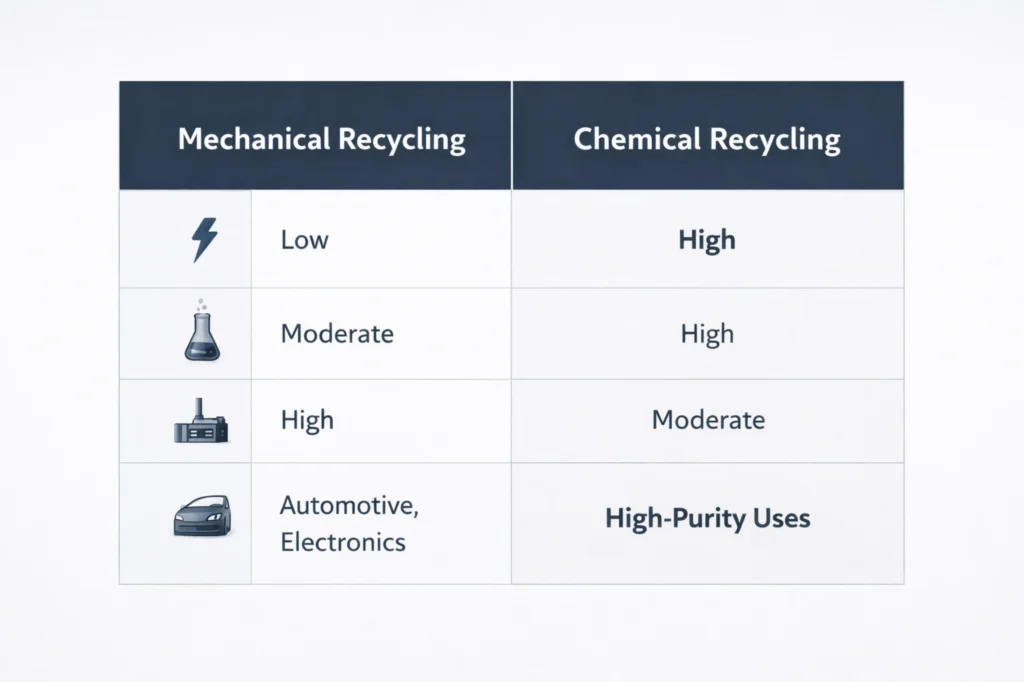

Mechanical vs Chemical Recycling of ABS

Choosing the right recycling method depends on the required end-use purity and the allowable budget. While mechanical recycling dominates the current market, chemical advancements are solving the problem of highly contaminated waste.

| Method | Energy Cost | Purity Level | Scalability | Primary Use Case |

| Mechanical | Low | Moderate (95–98%) | High | Hidden structural parts, pallets, conduits. |

| Chemical | High | Near-Virgin (99.9%) | Emerging | High-gloss housings, medical, food-contact. |

Mechanical Recycling: Feasibility, Cost, and Limits

Mechanical recycling is the industry standard because it is economically efficient and requires minimal infrastructure compared to chemical plants. However, it is governed by the law of diminishing returns known as “Heat History.”

- The Heat History Concept: Every time ABS passes through an extruder, the polymer chains experience thermal stress. This “heat history” causes chain scission, where the molecular weight of the plastic decreases.

- Property Drift: With each cycle, the material becomes more fluid (higher Melt Flow Index) but significantly more brittle.

- Cost Advantage: Mechanical regrind is typically 20%–40% cheaper than virgin resin, making it the first choice for non-critical components.

- The 20% Rule: To maintain structural integrity, manufacturers typically “fortify” mechanical regrind by blending it at a 20:80 ratio (recycled to virgin).

Chemical Recycling: Solvent-Based and Depolymerization Approaches

Chemical recycling breaks the plastic down at the molecular level, effectively “resetting” its heat history. This is the only way to achieve a “closed-loop” for high-end consumer electronics.

- Dissolution (Solvent-Based): This process involves dissolving ABS in specific solvents like Acetone or Methyl Ethyl Ketone (MEK). Once dissolved, the liquid is filtered to remove all pigments and flame retardants, and the ABS is then precipitated back into a pure solid.

- Depolymerization: Unlike Dissolution, this method uses heat or catalysts to break the polymer back into its base monomers: Acrylonitrile, Butadiene, and Styrene. These monomers are then re-polymerized into brand-new ABS.

- The Purity Benefit: Chemical recycling removes legacy additives (like BFRs) that mechanical processes cannot. This makes the resulting resin safe for regulated industries, though the cost currently remains equal to or higher than virgin resin.

Quality and Performance of Recycled ABS

Engineers must treat Recycled ABS (rABS) as a distinct material grade. While its tensile strength often remains comparable to virgin resin, its ability to withstand sudden energy, impact resistance is the first property to degrade.

Strength, Impact Resistance, and Thermal Changes

The mechanical profile of rABS shifts due to the degradation of the butadiene (rubber) component, which is highly sensitive to oxidation during reprocessing.

- Impact Strength Loss: Expect a 10% to 20% reduction in Izod Impact Strength with every heat cycle. The rubber particles that provide toughness harden, making the final part more prone to shattering under stress.

- Tensile Strength Stability: Tensile strength (resistance to being pulled apart) is surprisingly resilient, often retaining 90–95% of virgin values after the first two cycles.

- Melt Flow Index (MFI) Increase: As polymer chains break (chain scission), the material becomes “thinner” when melted. A higher MFI means you may need to adjust injection pressures to avoid “flash” (excess plastic) in the mold.

- Heat Deflection Temperature (HDT): The HDT typically remains stable, but the material becomes more susceptible to environmental stress cracking when exposed to chemicals or UV light.

How Many Recycling Cycles ABS Can Tolerate

The “lifespan” of ABS is not infinite. To maintain industrial safety standards, the industry follows a strict degradation threshold.

- The 3-to-5 Cycle Limit: Research indicates that ABS can withstand 3 to 5 full recycling cycles before the molecular structure collapses. Beyond this point, the material loses its “engineering” status and behaves like a low-grade commodity plastic.

- The Blending Standard: To circumvent degradation, manufacturers use a “Virgin-to-Regrind” ratio. A common industry benchmark is 75% virgin to 25% recycled content. This ratio effectively “dilutes” the heat history and keeps the physical properties within a 5% tolerance of the original spec.

- The “Yellowing” Indicator: Visual degradation often precedes mechanical failure. As the Styrene component oxidizes, the plastic develops a yellow or brownish tint, which is why recycled ABS is usually dyed black or dark grey to mask the quality shift.

Common Challenges in ABS Plastic Recycling

Recycling ABS is not a “plug-and-play” process. Manufacturers face significant chemical and aesthetic hurdles that can compromise the final product’s marketability and safety.

Flame Retardants, Additives, and Color Issues

The primary challenge in secondary ABS markets is managing the complex “chemical cocktail” added during the material’s first life.

- The Yellowing Problem: Thermal oxidation causes the Styrene molecules to form chromophores, resulting in a distinct yellow or brown tint. In light-colored applications, recyclers must use Titanium Dioxide (TiO2) as an opacifier to mask this yellowing, though this can increase the material’s abrasiveness on molding equipment.

- Contamination by BFRs: Flame retardants (Brominated Flame Retardants) do not disappear during melting. If a batch of recycled ABS contains unregulated BFRs from older electronics, it cannot be used for modern consumer goods due to strict environmental safety laws.

- Color Contamination: Because ABS is often dyed at the molecular level, it is nearly impossible to turn a “Mixed Color” regrind back into white or clear plastic. Consequently, 85% of recycled ABS is sold as Black, as it is the only color that can reliably cover inconsistencies.

Degradation, Odor, and Property Variability

Beyond visual defects, the chemical breakdown of the polymer during reprocessing creates functional issues that require specialized venting and testing.

- VOC Emissions & Odor: During the second or third melt, ABS releases Volatile Organic Compounds (VOCs). This results in a “burnt plastic” or acrid odor that can persist in the finished part. For interior automotive applications, high-grade vacuum degassing during extrusion is required to strip these odors.

- Butadiene Cross-linking: While some polymer chains break, the Butadiene (rubber) component can also “cross-link” or gel. These microscopic gels create “seeds” or surface imperfections, making it impossible to achieve a “Class A” high-gloss finish.

- Batch-to-Batch Variability: Unlike virgin resin, which has a fixed data sheet, rABS properties vary based on the feedstock. This variability in Melt Flow Index (MFI) forces injection molders to constantly recalibrate their machines, which increases scrap rates and downtime.

Uses of Recycled ABS in Manufacturing

The application of recycled ABS (rABS) is a strategic balance between sustainability goals and mechanical reality. While it is rarely used for primary structural shells in premium electronics, it is the industry standard for secondary components where cost-efficiency is the priority.

Injection Molding Applications and Part Limitations

In high-volume manufacturing, rABS is favored for its high flowability and low cost per unit. However, designers must account for its slightly higher brittleness.

- Primary Use Cases:

- Construction: Electrical conduits, junction boxes, and piping connectors.

- Logistics: Heavy-duty transport pallets and storage crates.

- Automotive: Hidden interior components such as seat belt housings, bracketry, and dashboard substructures.

- Consumer Goods: Vacuum cleaner internal motor housings and base plates.

- Design Limitations:

- Snap-fits: Avoid complex snap-fit designs with rABS. The reduced impact resistance makes these features prone to “crazing” or snapping during assembly.

- Surface Finish: Do not specify high-gloss or “piano black” finishes for 100% recycled content. Use a textured or matte mold surface to hide the “seeds” or gel particles common in regrind.

3D Printing: DIY Shredding vs. Professional Filament Quality

The 3D printing community is a major driver of ABS recycling, but there is a massive performance gap between “homemade” and “industrial” recycled filament.

- The DIY Challenge: Many hobbyists use desktop extruders to turn failed prints into new filament. The primary risk here is Diameter Consistency. Without a professional laser-controlled puller, variations in filament thickness (e.g., 1.75mm vs 1.85mm) will lead to extruder jams or under-extrusion.

- Professional rABS Filament: Industrial-grade recycled filament (like those from FormFutura or Reflow) undergoes a “melt filtration” step that DIY setups cannot replicate. This removes microscopic debris that would otherwise clog a 0.4mm nozzle.

- Hygroscopy Warning: Recycled ABS is more hygroscopic (moisture-absorbent) than virgin ABS due to the presence of micro-voids and degraded polymer chains.

- Fact: Printing with “wet” rABS causes steam bubbles in the layer lines, reducing inter-layer adhesion by up to 30%.

- Threshold: Always dry rABS filament at 80°C for at least 4 hours before use.

Recycled ABS vs Virgin ABS

For procurement officers and engineers, the choice between virgin and recycled ABS is rarely a simple binary. It is a trade-off between raw material savings and increased quality-control overhead.

Cost, Availability, and Supply Chain Differences

The economic profile of recycled ABS (rABS) differs significantly from virgin resin, primarily due to the volatility of plastic scrap markets and the necessity of rigorous validation.

- Price Advantage: On a per-ton basis, rABS typically costs 20% to 30% less than virgin ABS. However, this “savings” can be misleading if the manufacturer does not account for higher scrap rates during the molding process.

- The “Testing Tax”: Unlike virgin resin, which comes with a guaranteed Technical Data Sheet (TDS), rABS requires lot-by-lot testing. Manufacturers must budget for Melt Flow Index (MFI) and Izod Impact testing for every new shipment to ensure consistency.

- Supply Chain Resilience: Virgin ABS is tied to global oil and styrene prices. Recycled ABS is tied to local waste collection infrastructure. Utilizing rABS can insulate manufacturers from global energy price spikes but leaves them vulnerable to regional e-waste shortages.

When Recycled ABS Is a Bad Engineering Choice

Despite its sustainability benefits, there are specific “No-Go” zones where the degradation of polymer chains presents an unacceptable safety or commercial risk.

Avoid 100% Recycled ABS in the following applications:

- Medical Devices: rABS cannot guarantee the biocompatibility required for skin contact or surgical environments due to potential legacy contamination (BFRs/heavy metals).

- High-Pressure Valves & Fittings: The micro-voids and “gel” particles in rABS act as stress concentrators, making the material prone to catastrophic failure under hydraulic pressure.

- High-Gloss Consumer Electronics: If your product requires a “Piano Black” or mirror finish, rABS will fail. The impurities will cause “silver streaks” and surface pitting that no amount of mold polishing can fix.

- Structural Safety Components: Parts that must withstand a single, high-energy impact (e.g., helmet shells or car seat mounts) should never use unverified recycled content. The 15-20% drop in impact toughness is too high a liability.

- UV-Exposed Outdoor Parts: Recycled ABS has already undergone thermal oxidation; its UV resistance is significantly lower than virgin material, leading to rapid chalking and cracking if not heavily loaded with stabilizers.

Environmental and Economic Impact of ABS Recycling

Adopting recycled ABS (rABS) is no longer just an “eco-friendly” gesture; it is a strategic response to a changing global regulatory landscape and a volatile energy market.

Carbon Footprint Reduction and Waste Diversion

The environmental benefits of ABS recycling are measurable and provide significant leverage for companies aiming to meet ESG (Environmental, Social, and Governance) targets.

- Carbon Emissions Savings: Producing virgin ABS is energy-intensive, requiring significant petroleum extraction and chemical synthesis. Transitioning to rABS saves approximately 2kg of CO2 for every 1kg of plastic produced. This represents an 80% reduction in the carbon footprint compared to primary production.

- Energy Conservation: The energy required to mechanically re-process ABS is 60% to 85% lower than the energy needed to synthesize the three base monomers (Acrylonitrile, Butadiene, and Styrene) from scratch.

- Waste Diversion: ABS makes up a massive portion of the 50 million tons of e-waste generated annually. By creating a closed-loop system, manufacturers prevent high-value engineering resins from leaching toxic chemicals into groundwater in landfill environments.

Regulatory Pressure and OEM Sustainability Goals

Original Equipment Manufacturers (OEMs) in the automotive and electronics sectors are facing unprecedented legal requirements to incorporate recycled content.

- EU Circular Economy Action Plan: New directives are moving toward mandating a minimum percentage of post-consumer recycled (PCR) content in all new electronic housings by 2030.

- Extended Producer Responsibility (EPR): Governments are increasingly shifting the cost of waste management onto the producers. Companies that design for “Recyclability” (using pure ABS instead of complex blends) significantly lower their EPR tax liabilities.

- Consumer Sentiment: Market data shows that 60% of B2B buyers now prioritize suppliers with documented sustainability credentials. Using rABS allows manufacturers to market products as “Circular,” providing a competitive edge in government and enterprise tenders.

Is ABS Plastic Recycling Worth It for Manufacturers

To conclude, the “worth” of ABS recycling depends on the alignment between your part’s performance requirements and your brand’s sustainability commitments.

Decision Checklist Based on Part Requirements

| Requirement | Use Recycled ABS? | Recommendation |

| High Gloss / Aesthetic Finish | No | Use virgin or a 10% rABS blend. |

| Hidden Internal Bracket / Support | Yes | 100% rABS is highly cost-effective here. |

| High Impact / Safety Critical | No | Use Virgin; risk of brittle failure is too high. |

| Cost Reduction Target >15% | Yes | rABS is the most effective lever for cost-downs. |

| RoHS / REACH Compliance Needed | Caution | Only use certified, tested PCR batches. |

When to Consider Alternative Recyclable Plastics

If ABS recycling does not meet your technical or economic needs, consider these alternatives:

- rPET (Recycled Polyethylene Terephthalate): Better for food-contact or high-transparency needs.

- rPP (Recycled Polypropylene): Better for “living hinges” and parts requiring high chemical resistance at a lower price point than ABS.

- ABS/PC Blends: If you need the recycled benefits of ABS but require the superior heat resistance of Polycarbonate.

Final Takeaway for the Reader

ABS plastic recycling is an engineered solution, not a waste-management byproduct. For non-structural, non-aesthetic, and cost-sensitive industrial parts, it is the most efficient material choice available in the modern circular economy.

FAQs

Why is ABS plastic rarely accepted in curbside recycling?

Curbside programs primarily target commodity plastics like PET (#1) and HDPE (#2). ABS is a Resin Code #7 (Other) material. Furthermore, municipal Near-Infrared (NIR) sensors cannot detect Black ABS, the most common color for electronics causing it to be rejected as “residue” and sent to landfills.

How does recycling affect the mechanical properties of ABS?

The primary impact is on Izod Impact Strength, which typically drops by 10% to 20% per heat cycle due to the oxidation of the butadiene (rubber) component. Tensile strength remains relatively stable (retaining 90–95% of virgin values), but the material becomes significantly more brittle.

Can recycled ABS be used for food-contact applications?

Generally, no. ABS is not inherently food-safe, and recycled ABS (rABS) carries a high risk of legacy contamination from Brominated Flame Retardants (BFRs) or heavy metals found in e-waste. For food-grade requirements, rPET or virgin Polypropylene are the industry standards.

What is the “20:80 Rule” in ABS manufacturing?

The 20:80 rule is an engineering benchmark where manufacturers blend 20% recycled regrind with 80% virgin resin. This ratio “dilutes” the heat history of the recycled polymer, allowing the final part to maintain mechanical tolerances within 5% of virgin specifications.

How can I tell if a batch of recycled ABS is contaminated?

Beyond laboratory testing for RoHS compliance, practitioners use the Burn Test. Contaminated ABS or blends (like ABS/PVC) will produce different smoke densities and odors. Additionally, look for “Silver Streaking” or “Pitting” on the surface of molded parts, which indicates moisture or foreign polymer contamination.

Does recycled ABS require different processing temperatures?

Yes. Because the Melt Flow Index (MFI) increases as polymer chains break during recycling, rABS is “thinner” when molten. To prevent mold flash, engineers often lower the injection temperature by 5°C to 10°C or decrease the injection pressure compared to virgin settings.