Can You Heat Press Polyester Safely? A Professional Step-by-Step Guide

Polyester can be heat pressed successfully, but it is not as forgiving as natural fabrics.

When handled correctly, it delivers clean, durable results that many professionals rely on daily when handled incorrectly, it can permanently damage the garment within seconds.

This fabric sits in a high reward, high risk category. Its synthetic nature allows excellent transfers and vibrant finishes, yet that same structure reacts quickly to excess heat, pressure, or time.

This guide is written to remove guesswork, replace myths with facts, and help you approach polyester with precision rather than caution or overconfidence.

Quick Answer (Can Polyester Be Heat Pressed Safely)?

Yes, polyester can be heat pressed safely but only when specific limits are respected.

Unlike cotton, polyester has a much lower heat tolerance, which means success depends on controlled temperature, minimal pressure, and choosing the correct application method.

Most professional failures happen not because polyester is unsuitable, but because it’s treated like a standard fabric.

When pressed within a safe temperature range (typically 270–300°F / 130–150°C), using light pressure and the right technique, polyester performs reliably and produces long lasting results.

- Keep temperatures low and strictly controlled

- Use light pressure only, never heavy

- Results vary by method (HTV, sublimation, or alternatives)

Why Polyester Reacts Differently to Heat (Critical to Understand First)

Polyester Fiber Structure

Polyester is not a natural fiber like cotton or linen. It is a plastic-based synthetic material made from polymers, which behave very differently under heat. Instead of tolerating high temperatures, polyester softens as it warms up, much like plastic packaging or synthetic rope. This softening happens well before you see visible damage.

The key difference is melting versus burning. Cotton can scorch or burn when overheated, but polyester doesn’t burn the same way, it melts and reshapes.

Once that happens, the damage is permanent. Shine marks, texture changes, and distortion are not surface issues; they are structural changes caused by heat pushing the fiber past its tolerance limit.

What Happens When Polyester Overheats

- The fabric develops shiny press marks or heat lines, especially in darker colors

- The surface texture becomes flattened or slightly rippled

- The garment may warp, shrink, or lose its original shape

- Colors can shift or bleed due to dye migration

These changes occur because excess heat causes polyester fibers to soften and re-form under pressure. Once the fibers have melted, even slightly they do not return to their original structure after cooling. Unlike surface wrinkles or moisture-related issues, overheating alters the fabric at a molecular level. This is why damage from excessive heat pressing is permanent and cannot be corrected by washing, steaming, or repressing at a lower temperature.

Ideal Heat Press Settings for Polyester (Exact Numbers That Matter)

Settings Chart (100% Poly vs. Blends vs. Recycled Poly)

| Fabric Type | Temperature | Pressure | Time |

| 100% Polyester | 270–300°F (130–150°C) | Light | 8–12 sec |

| Poly–Cotton Blend | 285–305°F (140–152°C) | Light–Medium | 10–12 sec |

| Recycled Polyester | 260–285°F (127–140°C) | Light | 8–10 sec |

Recycled polyester typically has lower heat tolerance due to fiber processing and additives. When in doubt, start at the lowest range and increase cautiously after testing.

Temperature Range for Polyester (°F / °C)

Polyester requires significantly lower temperatures than cotton to avoid surface damage and fiber deformation.

Cotton is often pressed at 320–380°F (160–193°C), but those temperatures are unsafe for most polyester garments.

Polyester fibers begin to soften well below cotton’s working range, which is why applying “standard” heat press settings leads to shine marks, warping, or dye issues.

Safe temperature guidelines for polyester:

- 270–300°F (130–150°C) — safest range for most HTV applications

- Below 285°F (140°C) — preferred for thin or performance polyester

- Above 305°F (150°C) — high risk of surface damage

Staying within this range allows proper adhesion while keeping the fabric structure intact.

Pressure Settings (Why Light Pressure Is Non-Negotiable)

Polyester reacts to pressure the same way it reacts to heat: by softening and reshaping.

Excess pressure compresses the fibers while they are warm, which is why shiny marks and texture changes appear even at safe temperatures.

Light pressure allows the transfer to bond without forcing the fabric to flatten or distort.

Medium pressure is only acceptable when the transfer material explicitly requires it and the temperature is kept at the lower end of the safe range.

Important note: If you can feel the platen aggressively squeezing the fabric, the pressure is already too high for polyester.

Press Time (Seconds That Make or Break Results)

- Polyester typically requires 8–12 seconds per press, depending on the transfer type

- Longer press times increase the risk of fiber softening, even at safe temperatures

- Multiple short presses with cooling pauses are safer than one extended press

- Re-pressing should be done only when necessary and at reduced time

Polyester does not fail instantly, but heat exposure accumulates quickly. Managing time precisely allows proper adhesion while preventing gradual fiber deformation that leads to permanent surface damage.

Verifying Accuracy with Infrared Thermometers

Heat press displays are not always precise.

Infrared thermometers allow you to verify actual platen temperature before pressing polyester. Measure multiple points across the platen to detect hot spots, which are a common cause of shine marks and warping.

A variance of even 10–15°F (5–8°C) can push polyester beyond its safe limit.

Verifying temperature accuracy is one of the simplest ways to prevent avoidable damage while maintaining consistent results.

Heat Pressing Polyester by Method

Heat Transfer Vinyl (HTV) on Polyester

HTV works well on polyester only when the vinyl is designed for low temperature application.

Standard vinyls that require high heat and firm pressure increase the risk of shine marks, warping, and poor long term results.

The key is matching the vinyl’s activation requirements to polyester’s heat tolerance, not forcing the fabric to meet the vinyl’s needs.

When using HTV on polyester, focus on the following:

- Choose low temperature or “poly safe” vinyl types

- Apply light pressure and stay within the 270–300°F (130–150°C) range

- Use short press times and avoid extended re-pressing

- Allow full cooling before peeling to reduce fiber stress

When compatibility is respected, HTV bonds cleanly without compromising fabric integrity.

Sublimation on Polyester (Best Case Scenario)

Sublimation is often considered the best possible heat press method for polyester because the process is designed around synthetic fibers.

Polyester’s polymer structure allows sublimation inks to penetrate and bond directly with the fabric instead of sitting on the surface like vinyl or ink layers.

Under heat, sublimation ink converts into a gas and chemically bonds with the polyester fibers as they soften slightly.

Once cooled, the ink becomes part of the fabric itself rather than a separate layer. This is why sublimated designs do not crack, peel, or add texture.

The result is exceptional durability. Designs remain breathable, flexible, and resistant to washing and friction.

When correct temperatures and timing are used, sublimation delivers long lasting color with minimal risk of surface damage, making it the most stable option for polyester garments.

Screen Printing vs Heat Press on Polyester

- Screen printing requires curing inks at higher temperatures, which increases the risk of dye migration and fabric distortion on polyester

- Plastisol and similar inks often demand longer heat exposure, making temperature control more difficult

- Heat pressing allows precise control over temperature, pressure, and time, reducing unnecessary heat stress

- Heat press methods are more adaptable to low temperature workflows and short exposure cycles

For beginners and small scale production, heat pressing is generally the safer option.

It offers predictable settings, faster setup, and less cumulative heat exposure compared to traditional screen printing, especially when working with heat sensitive polyester fabrics.

DTF (Direct to Film) Industry Favorite for Synthetics

- DTF has become a preferred method for polyester because it combines lower heat requirements with strong adhesion.

- DTF typically apply within 260–290°F (127–143°C) using light to medium pressure and short press times.

- The adhesive bonds to the fabric surface without forcing the fibers to soften excessively. This reduces the risk of shine marks, warping, and dye migration, especially on dark polyester.

- For modern polyester garments, performance wear, and recycled fabrics, DTF offers a balanced solution between durability, safety, and production efficiency.

Common Heat Press Problems With Polyester (And How to Fix Them)

Shiny Press Marks and Heat Lines

Cause:

Shiny press marks and heat lines occur when polyester fibers soften under heat and are compressed by pressure. This is most visible on dark or smooth fabrics, where flattened fibers reflect light differently after pressing.

Prevention:

Use lower temperatures within the safe range, apply light pressure only, and place a protective sheet or cover fabric between the press and the garment. Avoid over pressing the same area.

Fix:

Once shine appears, it cannot be fully removed. Minor marks may be reduced by gently steaming the fabric or brushing the fibers, but structural shine caused by heat is permanent.

Shrinkage and Warping

Shrinkage and warping in polyester are usually linked to fabric quality and construction rather than a single pressing mistake.

Lower quality polyester uses thinner or uneven fibers that soften faster and lose shape under heat. When exposed to excessive temperature or pressure, these fibers contract or shift, causing distortion.

To prevent this, always stay within the lower end of the safe temperature range and avoid long press times.

Higher quality polyester garments are more heat stable and maintain their shape better, making fabric selection an important factor in consistent results.

Dye Migration and Color Bleeding

Dye migration occurs when heat causes dyes in polyester fabric especially dark or highly saturated colors to gas and move upward into the transfer material. This often results in discoloration, shadowing, or a tinted design that was originally a different color.

Dark fabrics are more prone to this issue because they contain higher dye concentrations.

To reduce risk, keep temperatures as low as possible and limit press time. Using blocking sheets or dye resistant barriers between the garment and transfer can help prevent dye movement. Once dye migration occurs, it cannot be reversed, making prevention essential when working with polyester.

Advanced Troubleshooting Can You “Reverse” a Scorch Mark?

- In most cases, no, true scorch or heat damage on polyester cannot be reversed. What looks like a scorch mark is usually fiber melting or compression, not surface residue. Once the fibers have softened and reshaped, cooling does not restore their original form.

- In very mild cases, where the issue is pressure related rather than heat related, gentle steaming or brushing may slightly reduce the appearance by lifting the fibers. However, this does not repair structural damage. If shine or texture change remains after cooling, the fabric has already passed its safe heat threshold. Prevention is the only reliable solution.

How to Heat Press Polyester Safely (Step-by-Step Process)

Pre Press Checklist

Before applying any transfer, always check the garment label for fiber content and heat recommendations.

Not all polyester fabrics are identical, and blends or performance materials may require lower settings.

Next, perform a test press on a hidden area or scrap fabric to confirm temperature, pressure, and time.

Finally, ensure the garment is completely dry. Moisture trapped in polyester can turn to steam under heat, increasing the risk of warping or uneven results.

Skipping these steps is one of the most common causes of avoidable damage.

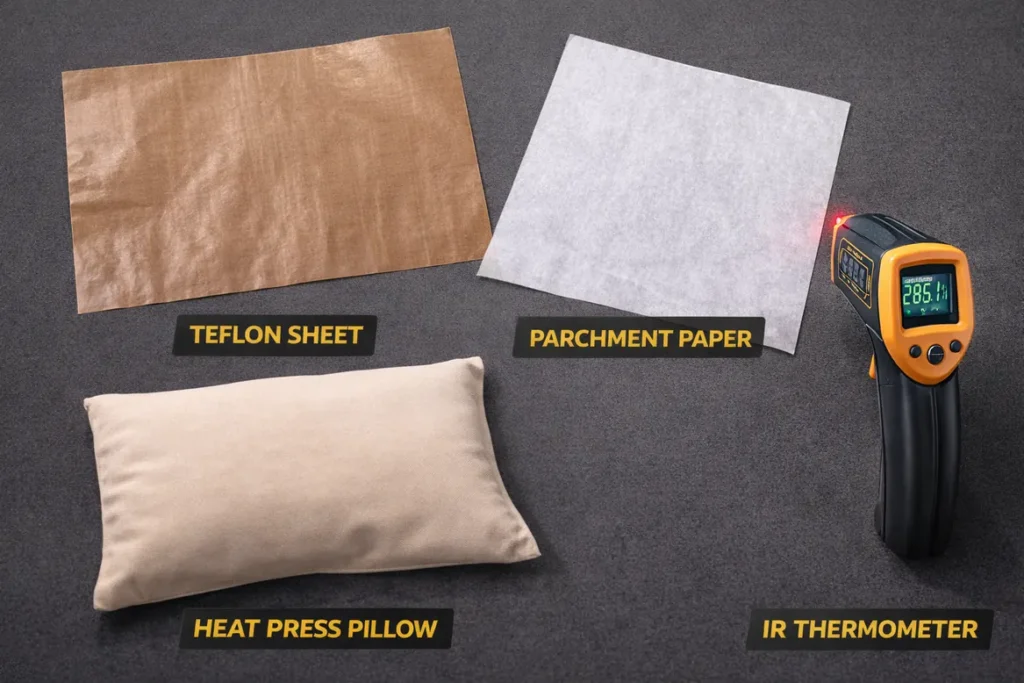

Protective Tools That Prevent Damage

Protective tools create a barrier between heat, pressure, and polyester fibers.

Teflon sheets or parchment paper help distribute heat evenly while preventing direct contact with the platen, reducing shine marks and heat lines.

A heat press pillow is especially useful for garments with seams, zippers, or uneven surfaces, as it absorbs excess pressure and prevents compression damage.

Using these tools does not reduce transfer quality; instead, they allow safer adhesion by controlling how heat and pressure reach the fabric.

Test Pressing Before Final Application

Always perform a test press on a hidden area such as an inside seam, hem, or spare piece of the same fabric.

This step helps verify that your temperature, pressure, and time are safe for the specific polyester garment.

During testing, watch for surface shine, texture changes, color shift, or warping. Also check how the transfer adheres after cooling. If any change appears during the test, adjust settings before proceeding.

A short test press prevents permanent damage on the final design.

The “Two-Press Method” (Tack vs. Final Set)

- The two-press method reduces heat stress by splitting application into controlled stages.

- The tack press uses lower temperature and shorter time to position and lightly adhere the transfer without fully activating it.This minimizes early fiber softening.

- After cooling, the final press completes adhesion using the minimum required time and pressure.

- This approach limits prolonged heat exposure in a single cycle, which is especially important for polyester. It also allows adjustments before full bonding, reducing mistakes while protecting fabric structure.

Heat Pressing Polyester Blends (What Changes?)

Polyester–Cotton Blends

Polyester–cotton blends are more forgiving than 100% polyester, but they still require adjusted settings. The cotton content increases heat tolerance, while the polyester portion remains sensitive to overheating.

This means standard cotton temperatures may still be too high, especially for blends with a higher polyester ratio.

To achieve consistent results, use moderate temperatures, light pressure, and shorter press times.

Always prioritize the polyester component when choosing settings. These blends are commonly used in everyday apparel, making them suitable for heat pressing when controlled settings are applied and test presses are not skipped.

Polyester–Spandex & Performance Fabrics

Polyester–spandex and performance fabrics require extra caution because elasticity increases heat sensitivity.

Spandex fibers degrade and lose stretch at lower temperatures than polyester, which can lead to permanent stiffness or distortion if overheated.

These fabrics are also thinner and often treated with moisture-wicking finishes that react poorly to excessive heat.

When pressing, use the lowest effective temperature, very light pressure, and short press times.

Avoid re-pressing whenever possible. Test pressing is critical with performance garments, as visual damage may appear minimal while elasticity loss occurs beneath the surface.

When You Should NOT Heat Press Polyester

There are situations where heat pressing polyester is technically possible but not advisable due to high risk of irreversible fabric damage. Recognizing these cases helps prevent costly mistakes and wasted garments.

- Ultra-thin or low-quality polyester that softens or distorts during a test press

- Dark, heavily dyed fabrics with a high risk of dye migration that cannot be blocked effectively

- Garments with special coatings or finishes, such as water-repellent or gloss treatments

- High-spandex performance wear where elasticity is critical to garment function

- Items with heat-sensitive decorations, reflective elements, or bonded seams

- Situations requiring high temperature or long press times beyond polyester’s safe range

In these cases, alternative decoration methods or lower-heat solutions are more reliable. Skipping heat pressing is often the safer professional decision.

Final Verdict (Is Heat Pressing Polyester Worth It?)

Heat pressing polyester is worth it when approached with precision and restraint.

For businesses, it offers consistency, speed, and professional results when settings are controlled and materials are compatible.

For hobbyists, it’s manageable as long as test pressing and protective tools are used.

Polyester is not difficult, but it is unforgiving of shortcuts. When low temperatures, light pressure, and correct methods are respected, heat pressing polyester delivers durable results without compromising fabric quality.

FAQs

Does polyester melt under a heat press?

Yes, polyester can melt under a heat press if temperatures are too high or pressure is excessive. It does not burn like cotton; instead, the fibers soften, flatten, or reshape permanently when overheated.

What is the safest temperature for polyester?

The safest temperature for polyester is generally 270–300°F (130–150°C). Staying within this range minimizes the risk of shine marks, warping, and dye migration while still allowing proper transfer adhesion.

Can you heat press 100% polyester without damage?

Yes, 100% polyester can be heat pressed without damage if low temperatures, light pressure, short press times, and proper protective tools are used. Skipping test presses significantly increases the risk of permanent fabric changes.

What fabric can you not heat press?

Fabrics that should not be heat pressed include nylon, silk, wool, leather, and fabrics with heavy spandex or special coatings. These materials either melt, scorch, shrink, or lose structure under heat, making safe heat pressing unreliable.

Can you heat press polyester cotton blend?

Yes, polyester–cotton blends can be heat pressed safely when using moderate temperatures, light pressure, and shorter press times. Always prioritize the polyester content, perform a test press, and avoid standard cotton heat settings.

Can you heat press polyester bags?

Yes, polyester bags can be heat pressed safely if they are heat-stable and uncoated. Use low temperatures, light pressure, and short press times, and always test first because bag thickness and coatings vary.

Can you heat press polyester sublimation?

Yes, sublimation is ideal for polyester. Sublimation ink bonds directly with polyester fibers under heat, creating permanent, crack-free designs that do not peel or fade when correct temperature and timing are used.

Why is my heat press leaving a square mark on my polyester shirt?

A square mark usually appears when heat and pressure are concentrated at the platen edges.

This happens when pressure is too high, temperature is near the upper limit, or no protective sheet or pillow is used.

Polyester fibers soften and compress unevenly, creating visible press outlines.

Reducing pressure, lowering temperature, and using a Teflon sheet or press pillow typically prevents this issue.