SLS vs FDM

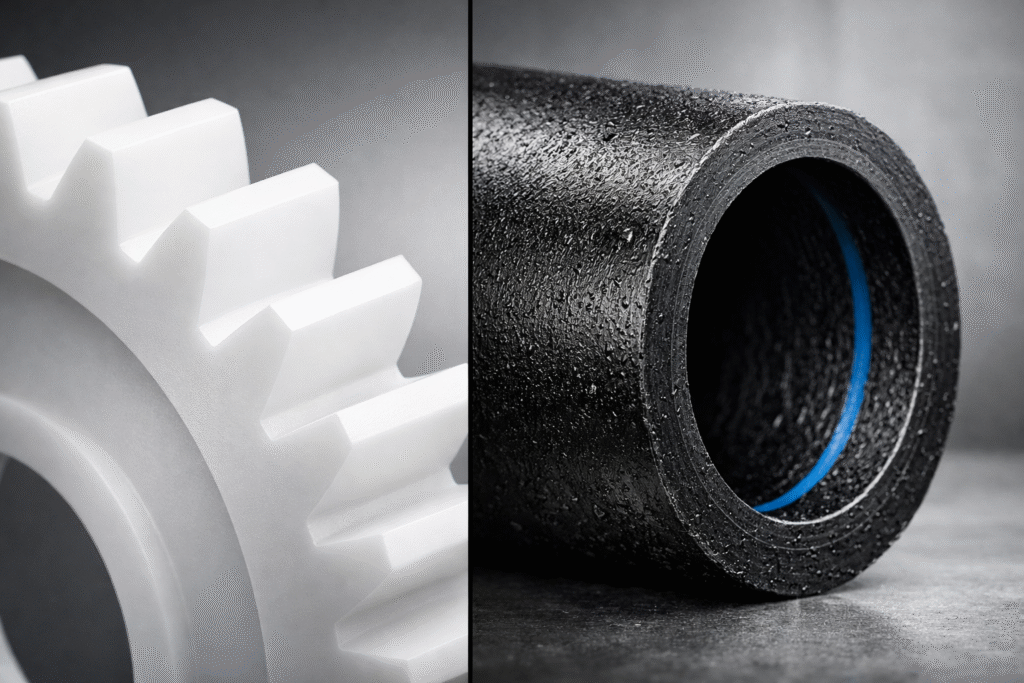

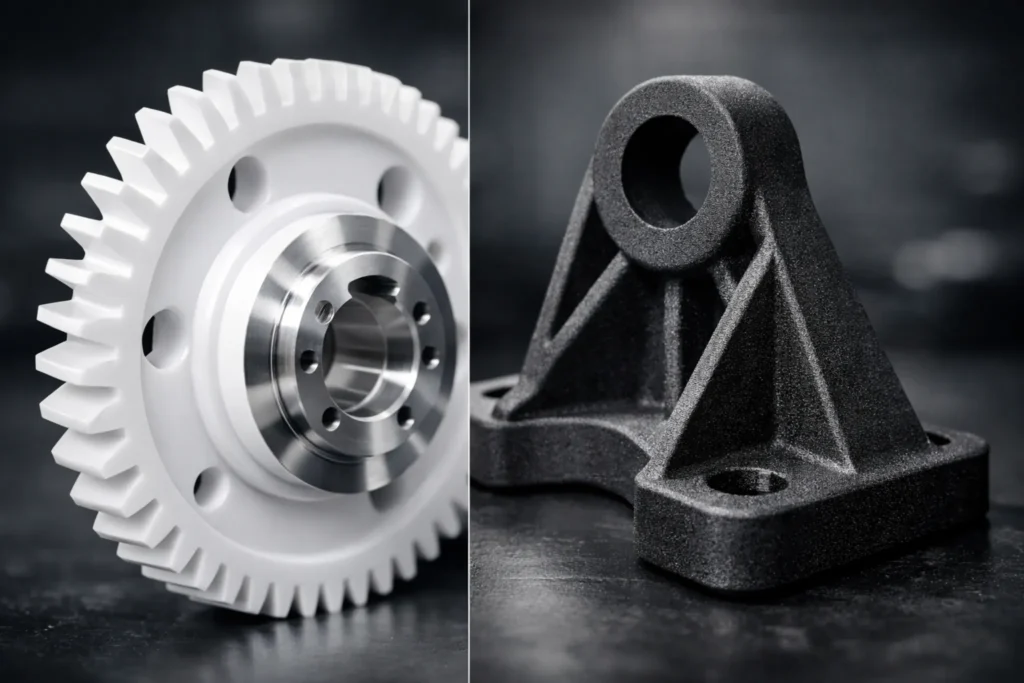

SLS vs FDM: Which 3D Printing Technology Is Right for Your Application? To choose between these technologies, evaluate your requirement for mechanical isotropic strength versus cost-effective scale. FDM (Fused Deposition Modeling) is the industry standard for low-cost, large-scale visual prototyping and simple jigs, while SLS (Selective Laser Sintering) is the superior choice for complex, high-performance functional parts and high-density batch production. In this technical SLS vs FDM comparison, […]