Delrin 100 vs. 150: The Engineer’s Guide to Acetal Homopolymer Selection

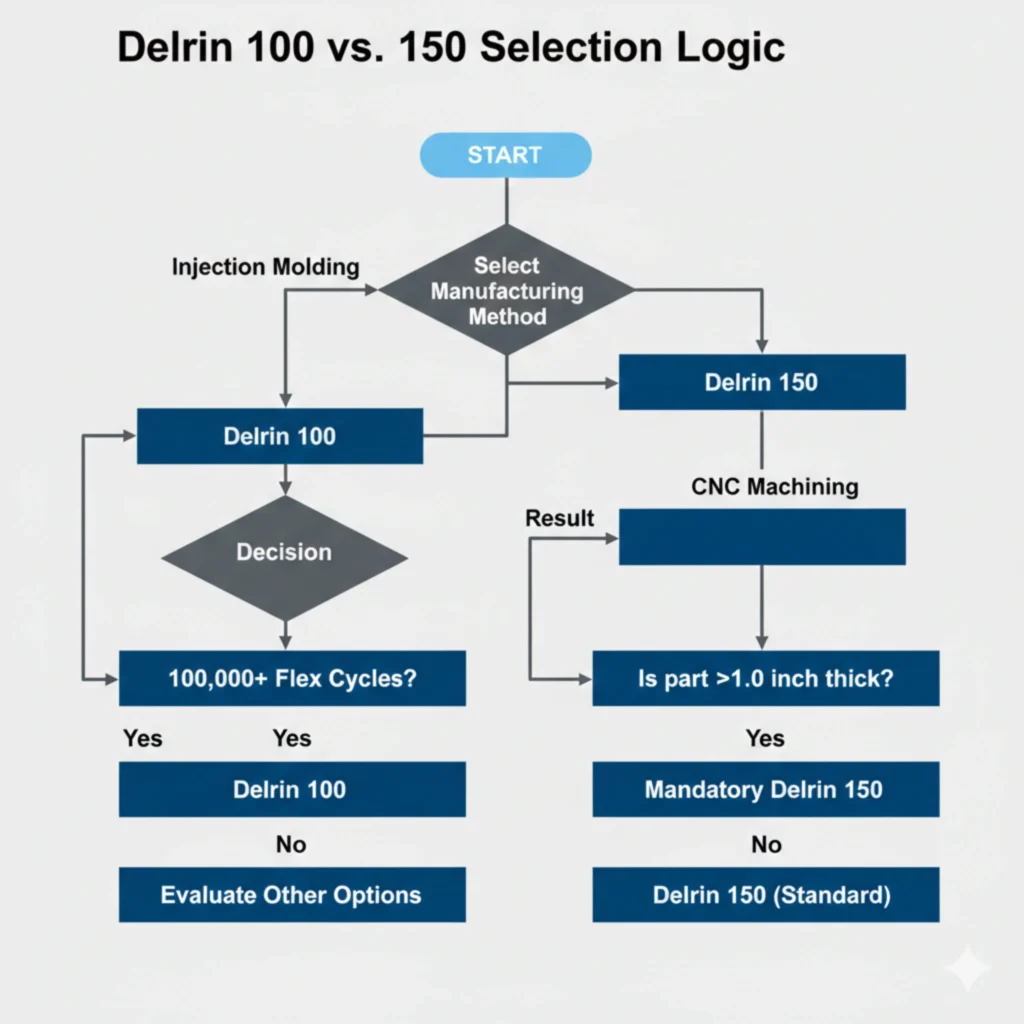

Define your manufacturing process before selecting a resin. Delrin 100 vs 150 is not a cosmetic comparison it is a critical processing decision that dictates part quality, tolerances, and production efficiency.

These two acetal homopolymers share a chemical backbone but serve different realities on the shop floor. Your choice depends on whether you intend to injection mold components at scale or CNC machine them from rod and plate stock.

Specifying the wrong grade risks warping, poor surface finish, and excessive tool wear. This guide clarifies these industrial trade-offs so you can specify based on data, not assumptions.

Executive Summary: Which Grade Should You Specify?

Use Delrin 100 For:

Specify this grade for high-volume injection molding where parts face repetitive stress. It provides the highest fatigue life and chemical resistance for snap-fits and living hinges.

Use Delrin 150 For:

Choose this grade for CNC machining from rods, plates, or tubes. Its formulation reduces internal stress, ensuring parts stay flat and hold dimensions after heavy material removal.

Comparison Table:

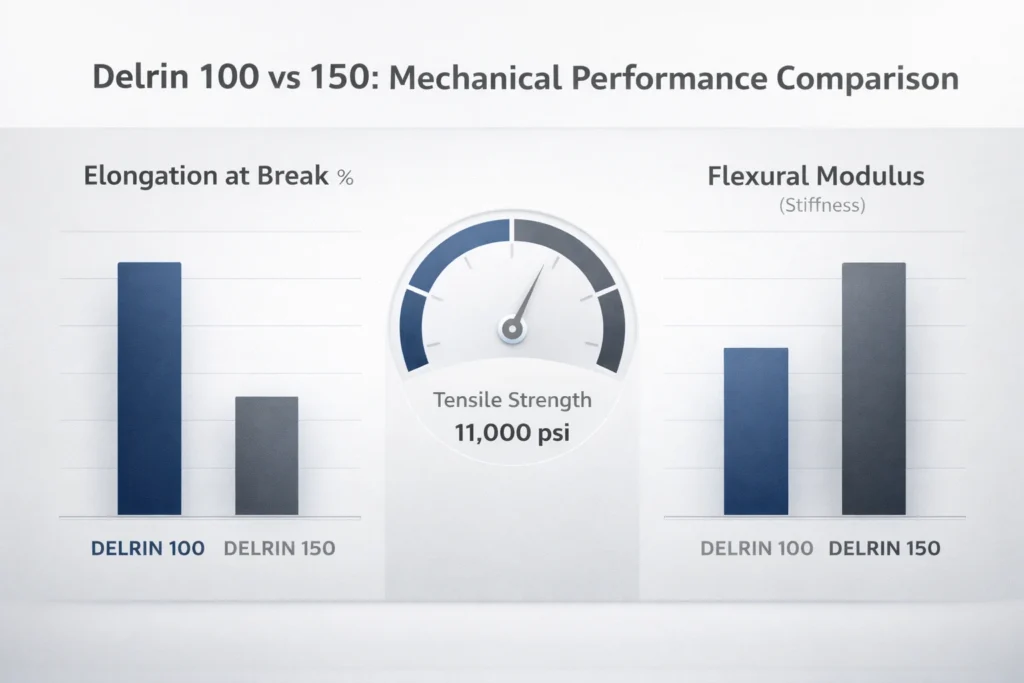

| Property | Delrin 100 (Molding) | Delrin 150 (Extruded) |

| Tensile Strength | 11,000 psi | 11,000 psi |

| Elongation at Break | 35% – 75% | 25% – 40% |

| Flexural Modulus | 420,000 psi | 450,000 psi |

| Water Absorption | 0.22% | 0.22% |

| Primary Format | Pellets | Rod / Sheet / Tube |

Align grade selection with your manufacturing method. While mechanical properties overlap, Delrin 100 is a high-viscosity resin for molding productivity, whereas Delrin 150 is a lower-stress resin tuned for precision cutting.

Selecting the wrong grade based solely on tensile strength ignores the centerline porosity risks inherent in machining molding-grade resins.

The Core Difference: Viscosity and Manufacturing Process

Delrin 100 (The Molding Grade)

Engineered for high-pressure injection molding, Delrin 100 features high melt viscosity and a tight molecular weight distribution. These long polymer chains allow molded parts to retain maximum fatigue resistance and creep performance during the cooling cycle.

The resin resists excessive shear thinning, which ensures uniform crystallinity even in complex geometries. This makes it the standard choice for high-volume gears and load-bearing snap-fits.

However, this high viscosity makes Delrin 100 difficult to extrude into thick stock shapes. Attempting to machine parts from molded 100 often reveals excessive internal stress and dimensional instability.

Delrin 150 (The Extrusion Grade)

Delrin 150 is the industry standard for extruded stock shapes like rods, plates, and tubes. Its formulation is tuned for flow stability through extrusion dies rather than high-pressure mold cavities.

This grade provides a dimensionally consistent material with significantly reduced internal stress. For the CNC shop, this translates into predictable tool engagement and cleaner chip formation.

While Delrin 150 has a slightly lower elongation percentage than 100, it gains the manufacturability required for precision-machined components. It is the default specification for most acetal homopolymer stock shapes.

The Myth of “Premium” vs. “Standard”

Do not categorize Delrin 100 as “premium” and 150 as “standard.” This hierarchy is technically incorrect. Neither resin is superior in isolation; they are process-specific solutions.

Select your grade based on the manufacturing method. Specify Delrin 100 for molded parts and Delrin 150 for machined components. Choosing based on a perceived quality hierarchy often leads to part failure or manufacturing bottlenecks.

Machinability and Performance in the Shop

Centerline Porosity: Why Delrin 150 is Mandatory for Large Parts

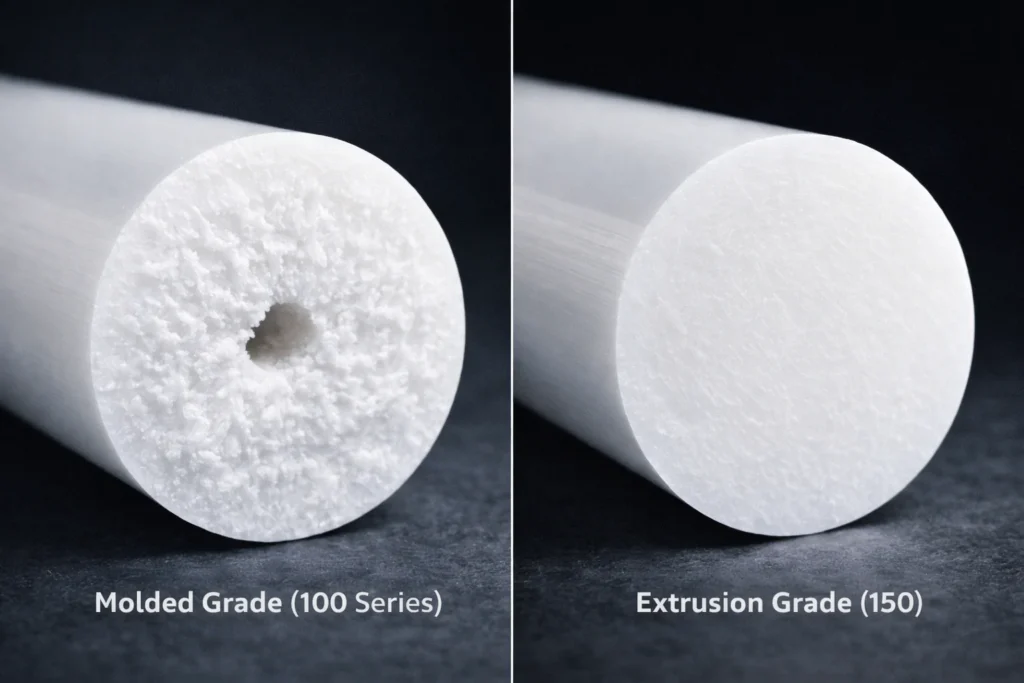

Centerline porosity is the most overlooked risk in acetal machining. During extrusion, material cools from the outside in, often creating a porous “pith” or void at the core.

Delrin 150 is specifically engineered to prevent this. Its melt index promotes uniform solidification, ensuring a dense, structurally sound core in rods and thick plates.

Molding-grade resins (like Delrin 100) are far more prone to these internal voids when extruded. This creates a hidden weakness that often results in structural failure only after the tool reaches the part’s center.

Maintaining Tight Tolerances and Dimensional Stability

Precision during machining depends on managing internal residual stress. Delrin 150 contains significantly lower stress levels than stock shapes forced from high-viscosity molding grades.

This stability is vital during heavy milling or deep drilling where stress relief causes parts to warp mid-operation. Delrin 150 remains stable as material is removed, allowing for tighter tolerances.

While Delrin 100 machines accurately in thin sections, the distortion risk increases exponentially as cross-sectional thickness and material removal rates rise.

Surface Finish and Texture Uniformity

Achieving a “mirror-like” finish requires material consistency. Delrin 150 cuts uniformly across the entire cross-section, ensuring a smooth finish without sudden texture changes as the tool moves inward.

In contrast, the density variations in Delrin 100 often lead to vibration or chatter when machining toward the core of thick stock.

For components where finish uniformity is a requirement, specify Delrin 150 to ensure predictable results and reduced secondary polishing time.

Mechanical Strength and Long-Term Durability

Fatigue Resistance: The Benchmark for Cyclic Loading

Fatigue resistance determines how a material survives millions of load cycles. Delrin 100 remains the industry reference for fatigue performance and is the default choice for snap-fits, living hinges, and high-cycle gears.

In rigorous environments, molded Delrin 100 parts endure millions of stress cycles without crack initiation. This mechanical stamina allows components to flex repeatedly while maintaining structural integrity.

While Delrin 150 performs reliably under moderate loads, do not specify it for designs where continuous flexing is the primary failure mode.

Impact Strength and Toughness: Absorbing Dynamic Energy

Toughness determines if a part absorbs energy or fractures under sudden shock. Delrin 100 exhibits superior impact tolerance, deforming slightly under dynamic loads rather than shattering.

This resilience improves survivability in assemblies exposed to vibration or abrupt load changes. It provides a safety margin in high-stress dynamic assemblies.

Delrin 150 behaves more rigidly, prioritizing stiffness and stability over energy absorption. This trade-off is ideal for rigid machined frames but less effective for impact-prone components.

Creep Resistance and Shape Retention Under Load

Specify Delrin 100 for components under sustained pressure or weight. Its high molecular weight ensures the material resists permanent deformation when stressed near its design limits for years.

This resilience makes it the standard for continuously loaded springs and structural clips. It maintains its original geometry effectively, preventing the part “set” common in lower-grade acetals.

Use Delrin 150 for rigid structural parts where loads remain within conservative ranges. While it offers stable performance, its priority is dimensional predictability during the machining process rather than maximum long-term resilience.

Environmental and Chemical Factors

Moisture Absorption: Dimensional Stability in High Humidity

Delrin homopolymers reach moisture saturation at 0.22% by weight. This is significantly lower than Nylon, which absorbs 2–8% depending on the grade and environment.

This minimal uptake ensures that Delrin retains its shape where Nylon softens and drifts out of tolerance. While both grades absorb moisture at the same rate, Delrin 150 exhibits more uniform swelling.

Its denser, more homogeneous core prevents the uneven growth often seen in lower-quality extrusions. In submerged applications, even 0.22% growth can cause binding, so engineer your clearances accordingly.

Temperature Limits: Performance in Extreme Thermal Cycles

Specify both grades for continuous service temperatures up to 180°F to 185°F. Thermal expansion remains predictable within this range, supporting stability during operation.

Choose Delrin 150 for machined housings requiring high heat deflection stability. Its lower internal stress improves tolerance retention during intermittent thermal exposure.

While the Heat Deflection Temperature (HDT) is nearly identical for both, the reduced stress in 150 prevents the warping that can occur when 100-grade parts are heated.

Chemical Resistance: Fuels, Solvents, and Bases

Both Delrin 100 and 150 are virtually immune to common industrial solvents, lubricants, and fuels. This makes them ideal for automotive and fuel-system components.

Do not expose these materials to strong acids (pH < 4) or oxidizing agents. These chemicals trigger rapid depolymerization, leading to irreversible material failure.

Cost Analysis and Sourcing Reality in 2026

Raw Material vs. Stock Shape Pricing

Direct cost comparisons only apply when considering the supply form. Delrin 100 is priced for high-volume pellet purchases aimed at injection molding operations.

In these applications, efficiency is driven by throughput and cycle time. Delrin 150 is rarely purchased as raw resin; it carries a processing premium as finished rod or plate stock.

This premium covers the cost of stress-relieving and centerless grinding. The higher price per kilogram reflects these essential downstream manufacturing savings rather than a difference in base chemistry.

Lead Times and Availability:

Current market behavior is predictable. Local and regional distributors almost exclusively stock Delrin 150 for sheet and rod because it meets machinist expectations for reliability.

While Delrin 100 pellets are widely available, sourcing Delrin 100 in rod form is often a “special order” with longer lead times and inconsistent quality.

Avoid these special orders for precision work. They often lack the centerline porosity controls found in 150, which introduces unnecessary risk for your CNC department.

Expert Recommendation: A Decision Matrix for Designers

When to Swap: Practical Specification Thresholds

Use these technical thresholds as a directive specification filter rather than a theoretical comparison of data sheets.

If your part thickness exceeds 1.0 inch, default to Delrin 150. This avoids the structural risk of centerline porosity and mid-operation warping common in molding-grade extrusions.

Specify Delrin 100 if the application requires 100,000+ flex cycles. Its superior molecular weight provides the mechanical stamina needed for high-stress snap-fits and living hinges.

For high-volume injection molding, utilize Delrin 100 for its fatigue life. For CNC machining from stock shapes, rely on Delrin 150 for predictable tolerance holding.

Specialized Alternatives: Beyond the 100 Series

When neither grade satisfies your design constraints, evaluate specialized alternatives rather than forcing a material compromise.

If your design requires lower friction, specify Delrin 100AF, which includes PTFE fibers. For higher stiffness at the cost of toughness, consider glass-filled acetals.

Nylon may reduce upfront material costs, but its moisture-driven dimensional change introduces a high risk of field failure. Match your material to the primary failure mode first.

Frequently Asked Questions (FAQ)

Is Delrin 150 stronger than 100?

No. Both grades share an identical tensile strength of approximately 11,000 psi. The difference lies in physical behavior: Delrin 100 is tougher and more fatigue-resistant, while Delrin 150 is stiffer and more dimensionally stable during machining.

Is Delrin 100 food safe?

Yes. Both Delrin 100 and 150 are available in formulations that comply with FDA, NSF, and USDA standards for food contact. Always verify with your supplier that the specific batch of resin or stock shape carries the necessary compliance certification for food-processing equipment.

Why is Delrin 150 the standard for plastic rod and sheet?

Delrin 150 is the extrusion standard because it minimizes centerline porosity the internal voids often found in other acetal homopolymers. Its lower internal stress allows it to stay flat and hold tight tolerances during CNC machining, making it the more reliable choice for stock shapes.