HTV vs DTF: Which Printing Method Is Better for Durability, Cost, and Production Scale?

When you’re deciding HTV vs DTF, you’re not choosing a trend — you’re choosing a production workflow.

The right transfer method depends on three operational questions:

- How long does it last?

- What does it cost over time?

- How many pieces can you produce without reprints?

This print method comparison breaks down what actually happens on press, what fails in wash tests, and which method scales cleanly.

Quick Verdict — Should You Choose HTV or DTF?

If you run small batches, want specialty textures, and don’t need full-color detail, heat transfer vinyl stays efficient and predictable.

If you produce multi-color designs, small text, or you need volume without weeding, direct to film printing wins fast.

Here’s the real decision filter:

- Use heat transfer vinyl when you need simple shapes, bold opacity, and premium texture

- Use direct-to-film printing when you need fine detail, multiple colors, and repeatable throughput

- Avoid choosing either based on “durability claims” alone as durability depends on adhesive activation, cure control, pressure, and garment compatibility.

Most shops don’t fail because of the print method. They fail because they ignore fabric behavior, heat press pressure, and reprint risk.

When HTV Is the Smarter Choice (Simplicity & Texture)

Heat transfer vinyl works best when you need consistency and control. You can isolate variables and reduce failure rates because the process is simple: cut, weed, press, peel.

HTV makes sense when:

- You print 1–20 pieces per design

- Your design uses 1–2 colors

- You want puff, flock, glitter, reflective, or thick raised finishes

- You control placement manually and can tolerate a slower production workflow

HTV also gives you clean color blocking without worrying about ink bleed, powder errors, or brittle film.

But your output speed depends on one thing: weeding time. That becomes the scaling wall.

When DTF Clearly Outperforms HTV (Detail & Volume)

Direct-to-film printing dominates whenever detail and throughput matter more than texture.

DTF wins when:

- Designs include gradients, photo detail, or fine text

- You produce 20–200 pieces per run

- You want consistent output across different garment colors

- You need fast repeatability with low labor costs

DTF also handles mixed order sets better; you can gang sheet multiple designs and press continuously. That reduces labor time and lowers reprint risk.

But DTF has one strict requirement: process control. If your cure, powder melt, or press settings drift, you’ll get brittle prints, poor stretch recovery, or wash failures.

How HTV and DTF Actually Differ in Real Production

Both are transfer methods, but the real difference is what carries the design.

HTV is a single material layer with adhesive.

DTF is a printed ink layer bonded to adhesive powder on a film.

That difference changes everything: margin of error, failure patterns, and scalability.

Application Process Differences (Pressing, Handling, Margin of Error)

The HTV application is forgiving if you know your press. You can see the vinyl, control alignment, and correct issues before full adhesion.

DTF is less forgiving because the adhesive and ink layer already exist. If you under-press, you get partial bonding. If you over-press, you can crush the film and reduce hand feel and stretch recovery.

Operational difference on press:

- HTV requires accurate cut + clean weed + correct peel timing

- DTF requires consistent heat press pressure + correct dwell + clean post-press

Where HTV often fails is prep and technique. Where DTF fails is temperature control and curing.

To reduce reprint risk:

- For HTV: ensure full adhesive activation and avoid under-pressure edges.

- For DTF: keep press temps stable and avoid over-curing in the shaker/oven

Material Interaction (Film Thickness, Stretch, Fabric Response)

Heat transfer vinyl adds a thicker layer, especially with specialty materials. That affects hand feel and fabric stretch. On athletic garments, thick vinyl can fight stretch recovery and start cracking earlier.

DTF lays down a thinner but more complex layer, ink + adhesive. It can stretch well, but only if cured properly. Poor curing makes the print brittle and leads to early cracking or edge lift.

Fabric response matters:

- HTV performs best on stable cotton and cotton blends

- DTF performs best across cotton, poly, blends, and many performance fabrics, but dye migration can ruin it fast

If your shop prints a wide garment mix, direct-to-film printing often reduces garment compatibility headaches.

Durability Comparison (Which Lasts Longer After Washing)?

Durability isn’t a brand claim. It’s what happens after 20–50 wash cycles under real use: heat, stretch, detergent, and drying stress.

In a proper print method comparison, you measure durability by:

- edge stability

- cracking resistance

- adhesive fatigue

- stretch recovery after washing

Both methods can last long when pressed correctly. Both can fail fast when rushed.

HTV Failure Patterns (Edge Lift, Cracking, Adhesive Fatigue)

Heat transfer vinyl durability problems usually start at the edges. Edge lift happens when adhesive activation is incomplete or the press pressure is uneven.

Common HTV failures:

- Edge lift after 5–10 washes (usually low pressure or short dwell)

- Cracking on stretch garments (vinyl too thick or wrong vinyl type)

- Adhesive fatigue from repeated heat cycles (dryer use accelerates it)

HTV also fails when operators rely on “warm peel” on vinyl that needs cold peel. That’s an irreversible mistake because it weakens the adhesive bond on the first pull.

Risk threshold: if you see edge lift at the corners after pressing, don’t ship it. Repress or redo.

DTF Failure Patterns (Over-curing, Migration, Brittle Films)

DTF durability failures are usually film-related. If the adhesive powder melts poorly or the ink cures incorrectly, the print becomes a brittle plastic sheet.

Common DTF failures:

- Brittle films that crack with stretch (over-curing or too much adhesive)

- Poor bond that peels in sheets (under-press or cold spots)

- Dye migration creating discoloration (polyester heat reaction)

- Over-pressing that flattens texture and reduces softness

DTF also fails when shops skip post-press or use inconsistent pressure. You can’t compensate later because the transfer already bonded imperfectly.

Risk threshold: if you can scratch the edge with a nail and lift the film, your press settings are wrong.

HTV vs DTF on Polyester, Blends, and Performance Fabrics

This is where most shops lose money. Polyester behaves differently from cotton, and performance fabrics amplify heat-related problems like dye migration.

You can’t choose a transfer method without asking: What fiber is this garment, and what’s the expected use?

HTV on Polyester (Where It Works and Where It Fails)

Heat transfer vinyl can work on polyester when you choose the correct vinyl and run lower press settings. But polyester doesn’t forgive heat mistakes.

HTV works well on polyester for:

- simple logos

- small chest marks

- low-stretch placements

- matte or reflective finishes

HTV fails on polyester when:

- The vinyl is too thick and restricts stretch recovery

- Press temps cause garment shine or scorch

- adhesion is weak due to lower heat and short dwell

Polyester also exposes edge lift because it’s smoother than cotton. If your heat press pressure is inconsistent, the corners start lifting quickly.

Threshold: if your vinyl bond feels “glassy” instead of embedded, you pressed too hot or too long.

DTF on Polyester (Heat Control, Migration, and Seam Risks)

Direct to film printing handles polyester better in terms of print detail and speed, but it introduces a major risk: dye migration.

Migration happens when heat pulls dye from polyester into the ink layer. It shows up as a red, yellow, or gray shift after pressing or after washing.

DTF on polyester works best when you:

- reduce press temperature

- control dwell time

- use a migration-blocking layer or proper ink system

- avoid high heat + long press cycles

DTF also struggles with seams and zipper areas. The film can bridge uneven surfaces and cause partial bonding or air pockets.

Irreversible mistake: pressing DTF across seams without adjusting pressure. You’ll get edge lift or gaps that fail after washing.

Cost, Speed, and Scalability (Which Makes Sense Long-Term)?

Cost isn’t just the material price. It’s how much time and waste your production workflow generates.

Your real cost comes from:

- labor time

- error rates

- reprint risk

- setup overhead

- long-run efficiency

Startup Cost vs. Per-Print Cost

Heat transfer vinyl has a lower startup barrier. A cutter and heat press can get you producing fast.

But HTV per-print cost increases with:

- multiple colors (layering)

- detailed designs (weeding time)

- large prints (material waste)

Direct to film printing often requires:

- DTF printer setup or outsourcing

- curing equipment or outsourced finishing

- consistent consumables

DTF per-print cost drops as volume increases because labor stays low. You don’t weed. You don’t layer. You press and go.

Threshold: if weeding takes longer than pressing, you’re already paying the “HTV tax” in labor.

Labor Time, Error Rates, and Reprint Risk

HTV labor is front-loaded. Your operator spends time cutting, weeding, and aligning. That increases error risk when you’re rushing.

DTF labor is press-loaded. Most time is spent on pressing and handling transfers, not preparing them.

Reprint risk pattern:

- HTV reprints happen from alignment errors, poor weeding, and wrong peel timing.

- DTF reprints happen from cure inconsistencies, migration, under-press, or dirty garments

DTF reduces operator fatigue because you remove weeding. That improves consistency when volume increases.

Print Feel, Stretch, and Customer Perception

Customers don’t talk about adhesive activation. They talk about how it feels and how it wears.

Your print method comparison must include hand feel, breathability, and stretch behavior.

Hand-Feel and Breathability Differences

Heat transfer vinyl typically feels thicker. On heavy cotton hoodies that can feel premium. On lightweight tees, it can feel like a patch.

DTF can feel softer, but only when you control ink density and adhesive powder. Heavy ink deposits create a plastic plate feel.

If your customers want lightweight fashion tees, DTF usually delivers better hand feel when applied correctly.

Risk threshold: if DTF feels stiff, your ink coverage or adhesive layer is too heavy.

Stretch Behavior on Activewear and Large Designs

Stretch recovery separates good prints from returns.

HTV can crack if the vinyl isn’t designed for stretch or if the print area is too large. The thicker the film, the worse it handles motion.

DTF can stretch well, but brittle films crack fast when over-cured. It also needs proper post-press to set the bond without crushing elasticity.

For activewear:

- Use HTV only if you use stretch vinyl and keep designs minimal

- Use DTF if your cure process is controlled and you avoid heavy ink builds

Where HTV Still Wins: Specialty Finishes (Puff, Flock, Glitter, Reflective)

This is HTV’s power zone. DTF can simulate effects, but it doesn’t match the tactile impact of true specialty vinyl.

HTV wins when you need:

- puff logos

- flock texture

- glitter blocks

- reflective safety finishes

If your brand sells premium texture, heat transfer vinyl supports that positioning. DTF stays primarily visual.

Common Mistakes When Choosing Between HTV and DTF

Most bad decisions happen because shops choose based on one variable: cost, durability, or “trend.” The correct choice depends on production workflow and garment compatibility.

Choosing HTV for the Wrong Design Types

Heat transfer vinyl fails as a strategy when your design complexity grows.

Avoid choosing HTV for:

- photo prints

- tiny text

- gradients

- multi-color artwork

Those designs explode weeding time and increase error rates. Layering multiple colors also increases thickness and reduces stretch recovery.

Irreversible mistake: using HTV for full-front multi-color designs at scale. Your labor cost will crush margins.

Choosing DTF Without Understanding Heat & Dye Behavior

DTF looks easy because it presses fast. But if you ignore heat behavior, you’ll ship failures.

Avoid choosing direct-to-film printing when:

- You can’t control press temp consistently

- You print high-poly garments without migration controls

- You use inconsistent pressure across different press zones

DTF also punishes shortcuts. If your curing is wrong, prints fail weeks later, not immediately. That’s the worst type of reprint risk it hits after customers wear it.

Risk threshold: if you see discoloration on poly garments right after pressing, stop and re-test. That’s migration starting.

Final Recommendation (Which Method Should YOU Use?

Choose based on your production workflow, garment mix, and design type. Don’t choose based on what other shops post online.

Heat transfer vinyl remains a strong transfer method when you focus on specialty looks and small runs.

Direct-to-film printing becomes the backbone when you need detail and volume with lower labor.

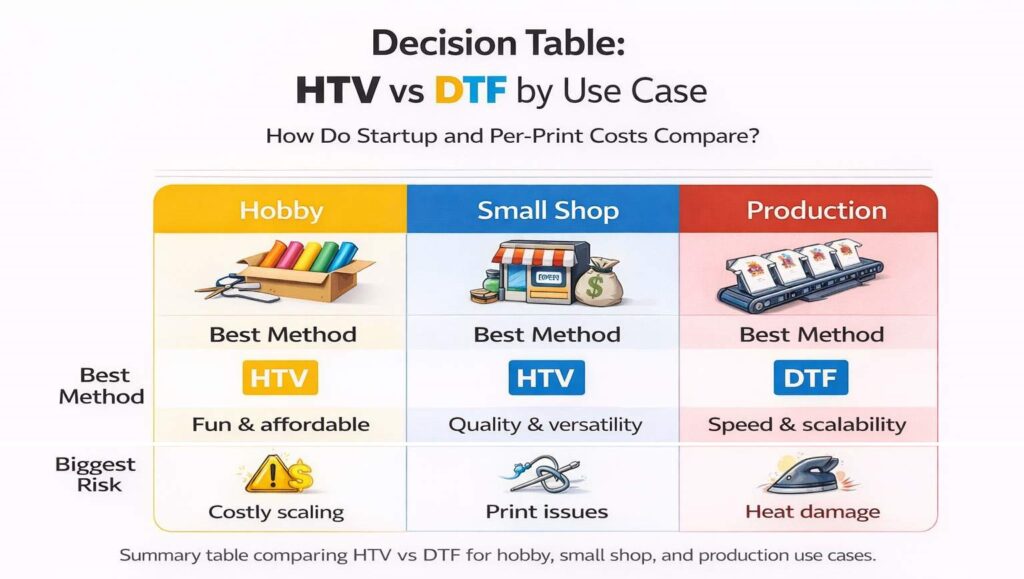

Decision Table by Use Case (Hobby, Small Shop, Production)

Use heat transfer vinyl when:

- You print small runs

- Designs are simple

- You sell specialty finishes

- You want a low startup cost

Use direct-to-film printing when:

- You print medium-to-high volume

- Designs include detail, gradients, or photos

- You need fast repeatability

- You want consistent output across many garment types

Hybrid workflow: combine both when each does a different job better.

Hybrid Workflow Approach: When to Mix HTV Neck Labels with DTF Chest Prints

This hybrid is practical and profitable.

Use heat transfer vinyl for:

- inside neck labels

- small one-color marks

- specialty branding touches

Use direct-to-film printing for:

- chest prints

- full-color artwork

- detailed back prints

This setup keeps your premium details where customers notice them while keeping production fast on high-impact placements.

Key Takeaways (Decision Summary)

- HTV vs DTF is a workflow decision, not a trend decision.

- Heat transfer vinyl wins on simplicity, texture, and specialty finishes.

- Direct to film printing wins on detail, volume, and multi-color speed.

- Durability depends more on heat press pressure, cure control, and garment compatibility than on the method itself.

- Polyester introduces the biggest risks: dye migration, heat damage, and seam press issues.

FAQs

What lasts longer, HTV or DTF?

DTF usually lasts longer when cured and pressed correctly, especially on blends and performance fabrics.

HTV can last just as long on cotton, but it’s more likely to fail by edge lift or cracking on stretch garments.

Is Heat Transfer the same as DTF?

No. DTF is a type of heat transfer, but not all heat transfer is DTF. Heat transfer includes methods like heat transfer vinyl and printed transfers, while direct to film printing specifically uses printed film + adhesive powder that gets heat-pressed onto the garment.

Can I put DTF over HTV?

Yes, but it’s high-risk and usually not recommended. DTF can bond over HTV only if the vinyl surface allows adhesion, but most HTV finishes reduce bonding and increase peel risk.

If you must layer, use DTF first and HTV second never rely on DTF as a top layer for long-term durability.

Is vinyl or DTF cheaper?

Vinyl (HTV) is cheaper to start, but DTF is usually cheaper per print at scale. HTV costs more in labor because of cutting, weeding, and layering, while direct to film printing lowers labor time and reduces reprint risk on detailed or multi-color designs.