MJF Nylon Engineering Guide (2026): Performance, Costs, and Production Design

MJF Nylon is the primary choice for 2026 production cycles where engineers require thousands of functional components without the lead times of traditional CNC machining.

In current manufacturing environments, Multi Jet Fusion systems deliver repeatable tolerances, high-density nesting, and stable unit economics across serial batches.

The process fuses PA12 and PA12S powders into near-isotropic parts, ensuring that internal ribs and snap-fits survive rigorous real-world duty cycles.

This allows teams to validate designs rapidly and scale immediately using identical material parameters across the entire production lifecycle.

With powder refresh rates now reaching 85% for newer grades, the cost-per-part remains predictable at high volume, making it a viable alternative to molding.

Integration of vapor smoothing further ensures these nylons meet strict cosmetic and hermetic sealing requirements for end-use deployment in demanding industries.

Defining MJF Nylon in Modern Manufacturing

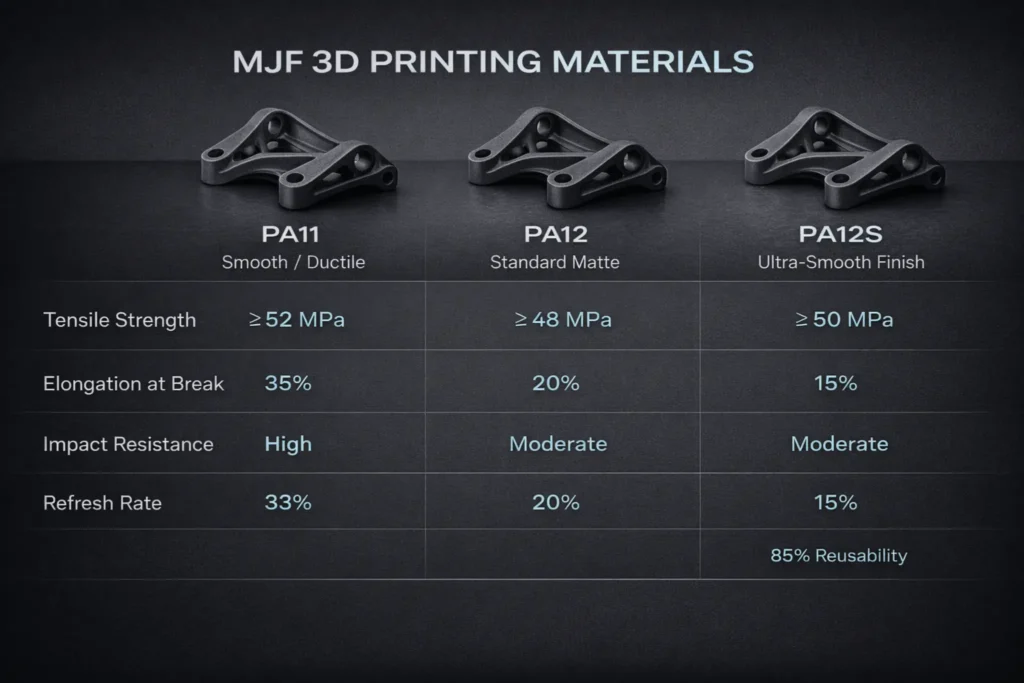

Why MJF Uses Polyamides (PA11, PA12, and PA12S)

Modern MJF Nylon production relies on polyamide powders because they melt within a highly controlled thermal window.

This stability allows for maximum nesting density packing parts within 2mm of each other without the risk of thermal bleed or warping.

PA12 remains the industry baseline for its stiffness-to-cost ratio, maintaining dimensional stability across thin-walled geometries and long structural spans.

For applications requiring high impact resistance, PA11 shifts the failure mode from brittle fracture to ductile deformation.

This bio-based polymer is essential for snap-fit assemblies and living hinges that must endure repetitive operational strain.

The newest 2026 standard, PA12S, reduces surface roughness to improve the consistency of vapor smoothing and reduce manual finishing labor.

Furthermore, the 85% reusability ratio of PA12S dramatically lowers the unit cost for high-volume production runs.

The Material Science: Why Nylon 6 and 6/6 Are Excluded

While Nylon 6 and 6/6 are staples of injection molding, they are functionally incompatible with the Multi Jet Fusion process for several reasons.

First, their melt viscosity is too high; they do not flow or fuse predictably, leading to high porosity and “cake” instability within the build chamber.

Second, these nylons are excessively hygroscopic (moisture-sensitive). During the powder handling phase, moisture absorption causes clumping, which ruins the thin-layer spreading required for MJF precision.

Finally, the thermal gradients required to stabilize Nylon 6/6 are too narrow, resulting in catastrophic part curl and dimensional drift.

For serial production throughput, refined polyamides like PA11 and PA12 remain the qualified standards for achieving predictable mechanical isotropy and stable economics.

Mechanical & Thermal Performance Limits

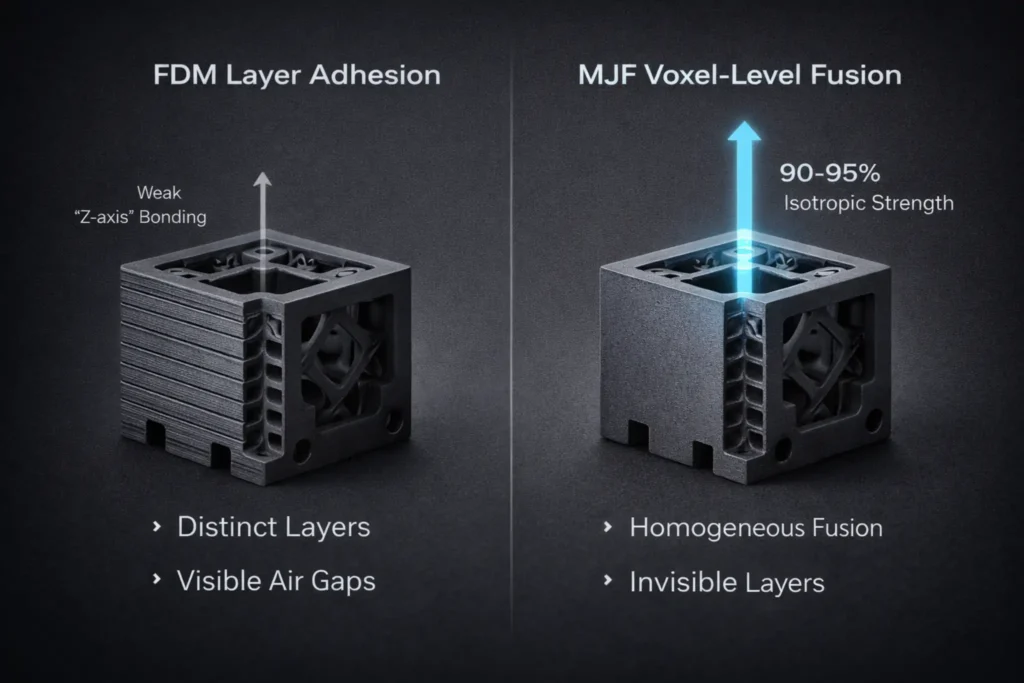

Isotropic Strength: The Z-Axis Advantage

Unlike traditional filament-based 3D printing, MJF Nylon produces parts with near-isotropic mechanical properties.

This advantage stems from the voxel-level fusion process, where the bond between layers is nearly as strong as the material within the layer itself.

In production, this means the typical Z-axis weakness often a 40-50% strength loss in other methods is reduced to a negligible 5-10% delta.

Engineers can design complex, load-bearing ribs and snap arms without fearing delamination when loaded out of plane.

To ensure consistency, you must validate tensile strength and elongation at break across all three axes during the first article inspection.

For high-stakes components, locking a specific nesting density is mandatory, as the thermal history of a dense build can slightly alter the final ductility of the parts.

HDT vs. Service Temperature

A common failure in MJF Nylon application is the conflation of Heat Deflection Temperature (HDT) with long-term service temperature.

HDT is merely a snapshot of stiffness under a specific load (typically 0.45 MPa or 1.82 MPa) and does not account for time-dependent deformation.

While the HDT for PA12 often reaches 175°C, this is not a safe operating window for functional parts.

For continuous use under moderate mechanical stress, you should treat 95°C as the practical ceiling.

Designing beyond this threshold frequently results in “heat sag” or dimensional drift in field conditions.

In 2026, practitioners apply a 50% de-rating factor to published HDT values for any component maintaining a structural load for over 1,000 hours.

Fatigue, Creep, and Moisture Resistance

While MJF Nylon is exceptionally durable, creep remains the primary failure mode in warm, sustained-load environments.

Polyamides are naturally hygroscopic (absorb moisture); as they do, their tensile modulus decreases while their impact resistance increases.

This shift can alter the fit of high-precision assemblies or the sealing effectiveness of vapor-smoothed surfaces.

To mitigate these risks, avoid sharp internal corners that act as stress risers and instead utilize generous fillets (minimum 0.5mm) to distribute fatigue loads.

When using mechanical fasteners, specify threaded metal inserts rather than direct-thread screws to prevent creep-induced loosening over time.

Finally, ensure all incoming inspections define the “as-conditioned” state to account for the predictable 0.5% to 1.0% dimensional shift that occurs as the material equilibrates with humidity.

MJF Nylon vs. Traditional & Additive Alternatives

MJF vs. Injection Molding: The 2026 “Break-Even” Point

Injection molding remains the gold standard for unit-cost efficiency once tooling is amortized, but MJF Nylon dominates the “Bridge-to-Production” and low-to-mid volume sectors.

In 2026, the economic shift depends on three variables:

The cost of a production-grade mold (typically $15,000–$60,000)

Stable molding unit cost ($1–$6)

The MJF unit cost ($8–$25).

For a typical industrial bracket, the break-even point often lands between 1,500 and 3,500 units.

Beyond simple unit economics, you must value the “cost of delay.” A $50,000 MJF production run allows for 1–5 day build-to-ship cycles and eliminates the risk of expensive mold rework if a design change occurs.

In volatile markets, the ability to execute parallel builds across multiple suppliers without duplicating tooling provides a massive supply chain advantage.

If your project involves high design churn or requires immediate market entry, the zero-tooling nature of Multi Jet Fusion is the most fiscally responsible path.

MJF vs. SLS Nylon: Throughput and Detail

While Selective Laser Sintering (SLS) is a reliable baseline, the decision to use MJF Nylon usually turns on production throughput and surface fidelity.

Multi Jet Fusion utilizes an inkjet array that applies fusing agents across the entire build width, whereas SLS relies on a single or dual laser point.

Consequently, MJF often completes dense builds faster, making it the preferred choice for high-volume serial production.

MJF also holds an edge in feature resolution, consistently producing sharper text and crisper edges in intricate geometries.

Surface quality is the final differentiator. SLS parts often exhibit a porous, “sugary” texture that requires intensive post-processing to seal.

In contrast, MJF parts are denser out of the machine and respond more predictably to vapor smoothing.

When selecting a supplier, demand documented Cp/Cpk data on critical features and a transparent powder reuse policy.

Because MJF supports higher powder refresh rates up to 85% for PA 12S, it provides a more stable long-term price point for recurring orders compared to traditional SLS workflows.

Critical Design Rules for Functional Parts

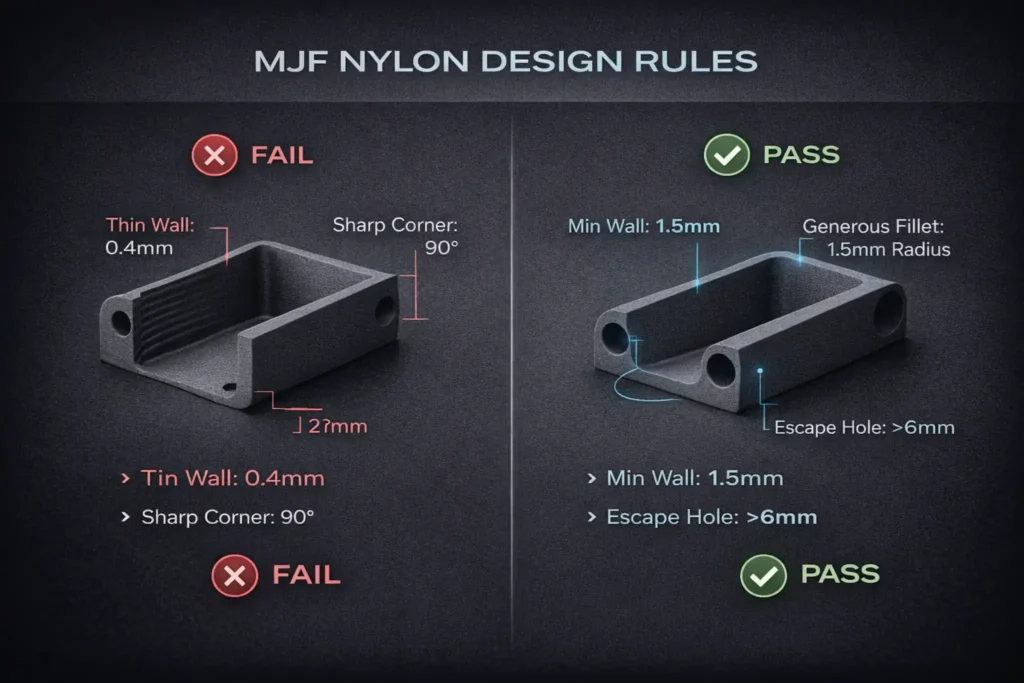

Wall Thickness and Feature Resolution

Successful MJF Nylon design requires an understanding of the build’s thermal mass.

While the technology can resolve features as small as 0.5 mm, these thin geometries rarely survive industrial post-processing like bead blasting or mass finishing.

For robust production, you should maintain a minimum wall thickness of 1.0–1.5 mm for non-structural shells.

Increase this to 2.0–3.0 mm for load-bearing housings to prevent failure modes in functional applications.

When designing fastener bosses, ensure the outer diameter is at least 2.5× the screw diameter to prevent hoop stress fractures.

Ribs should be designed at 50–70% of the adjacent wall thickness to avoid localized heat sinks that cause surface sink marks.

Always lock your finishing requirements early; aggressive vapor smoothing will round sharp edges and soften embossed text.

Compensate for this by increasing text stroke widths to at least 0.5 mm to ensure legibility after processing.

Hollowing and Powder Escape Strategies

Hollowing large volumes is a primary strategy for reducing material costs, yet it only provides value when powder removal is 100% predictable.

Trapped, un-fused powder adds unnecessary weight and can eventually leak, leading to field failures and customer complaints.

To ensure reliable evacuation, you must incorporate at least two escape holes per internal cavity, placed on opposite ends to prevent powder bridging.

We recommend a minimum hole diameter of 6–8 mm for effective material flow.

Avoid designing long, serpentine internal tubes that lack direct access for compressed air or vibration tools.

Remember that the manual labor required to clear complex internal voids can quickly erase any material savings; plan your clean-out method before committing to a hollow design.

Snap Fits, Living Hinges, and Tolerances

Snap fits in MJF Nylon perform exceptionally well if the design keeps strain within the material’s elastic zone.

Sharp internal corners at the base of a snap arm are the most common cause of premature fatigue; applying a fillet radius of 0.8–1.5 mm is mandatory to redistribute these stresses.

For living hinges, PA11 is the superior choice over PA12 due to its higher elongation at break.

Regardless of material, you must prototype the hinge in the exact orientation used for final production to ensure consistent performance.

Regarding tolerances, ignore marketing “best-case” numbers and design for real-world capability.

A general production tolerance of ±0.3 mm is a safe baseline for parts up to 100 mm.

For press-fits, provide an initial clearance of 0.1–0.2 mm and tune the geometry after the first article inspection.

Finally, for high-torque applications, always prefer heat-set metal inserts over printed threads to ensure long-term assembly integrity and prevent creep-induced stripping.

Post-Processing & Surface Engineering

Vapor Smoothing for Airtight/Watertight Performance

Vapor smoothing is no longer just a cosmetic luxury in 2026; it is a critical engineering step for functional MJF Nylon components.

By exposing parts to a suspended solvent vapor, the surface “reflows,” effectively sealing micro-porosity inherent in powder-bed fusion.

This process is essential for manifolds, fluid-handling ducts, and airtight enclosures. Beyond sealing, it significantly improves mechanical ductility by eliminating surface crack initiation points, which can increase elongation-at-break performance.

However, engineers must account for the dimensional “rounding” effect. Vapor smoothing typically removes or shifts 0.05mm to 0.1mm of surface material.

This can soften sharp edges and tighten internal diameters. If your application requires high-precision sealing faces, design those features with additional machining stock or plan for post-print reaming.

To ensure a stable manufacturing window, validate your leak-rate targets using parts from the hottest zones of a maximum-density build.

Dyeing and Coating for End-Use Aesthetics

Standard MJF Nylon emerges from the build as a matte grey or charcoal, which may not meet consumer-facing or UV-exposed requirements.

For high-throughput color, deep-immersion dyeing is the most efficient method, but its success depends heavily on the surface openness of the part.

In 2026, practitioners recognize that powder refresh rates such as the 85% reusability of PA 12S, directly impact dye uptake and color consistency across lots.

When your parts face outdoor environments or harsh chemicals, switch from dyes to high-performance coatings like Cerakote or UV-stable polyurethanes.

While dyeing offers no added thickness, coatings can add 0.02mm to 0.05mm, which must be accounted for in your tolerance stack, especially at snap-fit interfaces.

For the best results in 2026, the industry standard is to sequence vapor smoothing before dyeing; this creates a uniform surface energy that results in a professional, injection-molded appearance.

Sustainability and Production Economics

Powder Reusability: The Cost-per-Part Driver

In the 2026 production landscape, powder reusability specifically the “refresh rate” is the single largest driver of MJF Nylon unit economics.

Standard PA12 typically requires a 30% fresh powder infusion per build to maintain mechanical integrity.

However, the introduction of PA 12S has shifted this baseline, allowing for an 85% reusability ratio.

For high-volume production, this 15% refresh requirement slashes material overhead and reduces “cost-per-part” volatility.

To optimize your budget, you must design for high nesting density; a loosely packed build increases the volume of “overflow” powder subjected to thermal aging.

Professionals now manage MJF builds by tracking “grams per cubic centimeter” of the build volume to ensure the highest possible yield from every kilogram of feedstock.

Bio-Based PA11: Low-Carbon Production

For organizations prioritizing carbon-neutral supply chains, PA11 serves as the primary technical alternative to petroleum-based polymers.

Derived entirely from renewable castor oil, PA11 offers a significantly lower carbon footprint than traditional Nylon 6 or PA12.

In 2026, this material is a strategic requirement for automotive and consumer-facing brands fulfilling “green manufacturing” mandates.

While PA11 carries a slightly higher raw material cost, its superior impact resistance and ductility often allow for thinner wall designs, which can offset the price premium.

When selecting PA11, ensure your supplier provides a certified mass-balance report to validate the bio-content, as this documentation is now standard for enterprise-level sustainability auditing.

Final Decision Matrix: Is MJF Nylon Right for You?

The “Go/No-Go” Engineering Checklist

Before committing to a high-volume production run in 2026, evaluate your project against these operational requirements.

MJF Nylon is the optimal choice if your application satisfies at least four of the following criteria:

- Quantity: Your production volume falls between 50 and 2,500 units, making the $30,000+ cost of an injection mold difficult to justify.

- Isotropy: The part requires structural integrity in the Z-axis (vertical) to survive out-of-plane loading or snap-fit assemblies.

- Lead Time: You require end-use, “serial quality” parts delivered in under 10 business days to meet critical market windows.

- Geometry: The design features internal lattices, complex fluid channels, or topology-optimized shapes that are impossible to machine or mold.

- Material Performance: The application demands the specific chemical resistance and 85°C–95°C continuous-use temperature profile of Polyamide 12.

- Sustainability: Your ESG mandates require a bio-based feedstock (PA11) or a low-waste process with high (85%) powder reusability.

Risk Assessment: When to Avoid MJF

While versatile, MJF Nylon is not a universal solution. Engineers should pivot to traditional manufacturing or alternative 3D processes when the following risks are present:

First, avoid MJF for large, flat, thin-walled plates. Large surface areas are prone to thermal warping during the cooling phase, especially in high-density builds.

If your part exceeds 300mm in a single flat dimension, CNC machining or reinforced SLS may offer better flatness control.

Second, do not specify MJF for high-load continuous service above 120°C.

Despite the high HDT ratings, the material will eventually succumb to creep and dimensional sag under sustained thermal stress.

Finally, if your unit volume exceeds 10,000 pieces, the “per-part” cost of MJF will lose its competitive edge against high-cavity injection molding.

Use MJF as a “bridge-to-production” strategy in these cases, but ensure your design is optimized for molding from day one to avoid expensive redesigns later.

FAQs

Is MJF Nylon 100% waterproof for industrial use?

Yes, MJF Nylon (PA12) parts can achieve IP66 and IP67 waterproof ratings without additional post-processing. Because MJF parts are denser and less porous than SLS alternatives, they are suitable for high-pressure fluid manifolds and watertight enclosures, provided a minimum wall thickness of 1mm to 2mm is maintained.

What is the difference between MJF PA12 and PA12S?

PA12S is an updated 2026 material standard that offers a smoother surface finish and higher powder reusability (up to 85%) compared to standard PA12. While mechanical properties remain similar, PA12S significantly reduces post-processing labor and unit costs for high-volume serial production.

Can MJF Nylon replace injection molding for production parts?

MJF Nylon typically becomes more cost-effective than injection molding for production volumes between 1,500 and 3,500 units. Beyond this “break-even point,” the high speed of MJF fusing entire layers at once allows for “bridge-to-production” without the $15,000–$60,000 upfront cost of traditional steel tooling.

Is MJF Nylon considered isotropic?

Yes, MJF Nylon is nearly isotropic, meaning it exhibits consistent mechanical strength in the X, Y, and Z directions. Unlike FDM or SLS, which can suffer a 40-50% strength loss in the Z-axis, MJF parts typically show only a negligible 5-10% delta, making them reliable for complex, multi-directional load-bearing applications.

When should I choose PA11 over PA12 in MJF?

Choose PA11 for applications requiring superior impact resistance, ductility, and flexibility, such as living hinges or snap-fit assemblies. PA11 is also the preferred “green” choice as it is a bio-based polymer derived from renewable castor oil.