MJF vs SLS: The 2026 Engineering Guide to Choosing the Right Powder Bed Fusion for Production

The 60-Second Verdict: When to Pick MJF vs SLS

Selecting between MJF vs SLS for industrial production depends on three variables: geometric complexity, mechanical isotropy, and unit volume. While both use powder bed fusion, MJF excels in high-throughput environments requiring uniform structural integrity.

Conversely, SLS remains the definitive choice for specialized, high-performance materials and large-format industrial components that exceed standard build envelopes.

Use the data below to identify the optimal process for your 2026 production requirements.

| Feature | Multi Jet Fusion (MJF) | Selective Laser Sintering (SLS) |

| Heat Source | Infrared Lamps & Fusing Agents | CO2 or Fiber Laser |

| Isotropy (Z-axis) | Superior (Near 95%) | Moderate (Anisotropic) |

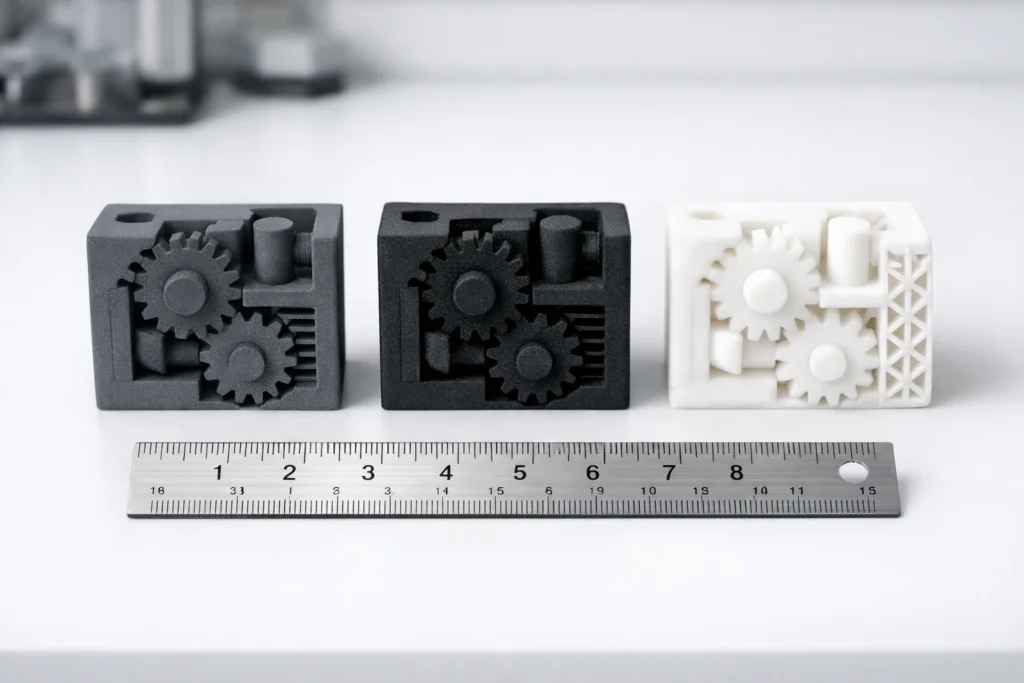

| Surface Finish | Smooth, Matte Charcoal | Grainy, “Sugar-like” White |

| Best For | High-Volume Functional Parts | Specialized Materials & Prototypes |

Key Decision Drivers: Strength, Surface, and Volume

- Isotropic Reliability: MJF parts exhibit uniform mechanical properties in X, Y, and Z planes; SLS often faces Z-axis delamination risks under high stress.

- Surface Aesthetics: MJF produces a denser, smoother surface out of the machine; SLS requires aggressive media blasting to achieve comparable quality.

- Production Velocity: MJF processes entire layers simultaneously, offering a significant lead-time advantage for batches exceeding 50 units.

The “Break-Even” Point: Where MJF Becomes More Profitable Than SLS

For low-volume prototyping (1–5 units), SLS is more cost-effective due to lower setup requirements and wider availability of small-frame machines.

As you scale toward medium-batch production, MJF’s speed becomes the dominant factor. In 2026, the industrial break-even point typically sits at 50 units.

Beyond this, MJF’s ability to utilize 80% recycled powder and faster build cycles drive the cost-per-part significantly lower than point-by-point laser sintering.

Mechanical Performance & The “Isotropy” Advantage

The “Physics of Fusion” creates the primary performance divide between these two technologies. While SLS relies on a point-to-point CO2 laser, MJF utilizes infrared lamps to fuse entire cross-sections of the build bed simultaneously.

By applying detailing and fusing agents, MJF achieves a more uniform thermal profile across the part. This precision prevents the localized “hot spots” common in laser-based systems, resulting in superior material density and structural reliability.

Tensile Strength & Elongation: PA12 vs PA11 Real-World Data

Engineers must distinguish between (PA12 vs PA11) raw material specifications and “as-printed” results. In 2026, PA12 remains the industry benchmark for stiffness, while PA11 is preferred for impact resistance and elongation.

MJF generally yields higher Ultimate Tensile Strength (UTS) due to the agent-based fusion process creating a more homogenous polymer matrix. SLS parts, while stiff, often exhibit lower elongation at break because of microscopic voids between laser paths.

| Property (PA12) | MJF Result | SLS Result |

| Tensile Strength (XY) | 48–50 MPa | 45–48 MPa |

| Tensile Strength (Z) | 47–49 MPa | 42–44 MPa |

| Elongation at Break | 18–20% | 14–16% |

Understanding Z-Axis Weakness: Why SLS Parts Fail Under Vertical Load

In SLS, the laser fuses the current layer to the one below it through localized heat. This often results in “inter-layer weakness” or anisotropy, where the part is significantly weaker when pulled apart vertically.

Under heavy mechanical stress, SLS parts are prone to delamination, where the layers literally peel apart at the fusion boundary. Conversely, MJF achieves nearly 95% isotropy, meaning strength is nearly identical in all directions.

This makes MJF the superior choice for functional housings, pressure vessels, and load-bearing brackets where the direction of stress cannot always be predicted during the design phase.

Fatigue Resistance and Life-Cycle Durability in Industrial Environments

Long-term part survival depends on how a material handles repeated stress cycles. The consistent thermal environment of the MJF build chamber ensures that parts cool at a uniform rate, significantly reducing residual internal stresses.

In contrast, the rapid heating and cooling cycles of SLS lasers can introduce “micro-stresses” into the polymer structure. Over thousands of cycles, these stresses act as fracture initiation points, leading to premature fatigue failure.

For industrial applications such as automotive ducting or aerospace interior components, MJF’s stable thermal history translates to higher cycle counts and predictable long-term durability in fluctuating temperatures.

Material Realities: Why SLS Still Holds the “Exotic” Crown

While MJF dominates in throughput, SLS remains the undisputed leader for specialized material requirements. The open-platform nature of SLS allows for a broader spectrum of polymer development, catering to niche industrial demands.

If your application requires specific thermal, chemical, or conductive properties beyond standard nylons, the laser-based sintering ecosystem offers a mature catalog of high-performance powders that agent-based systems cannot yet replicate with the same precision.

Engineering-Grade Nylons: PA 12, PA 11, and Glass-Filled Options

- Polyamide 12 (PA 12): The industry standard for both processes, offering high stiffness and excellent chemical resistance to oils and fuels.

- Polyamide 11 (PA 11): A bio-derived polymer preferred for its superior impact resistance and high elongation at break in aerospace and medical sectors.

- Glass-Filled (GF) Composites: Both systems utilize glass-bead reinforcement to increase structural rigidity and minimize warping in large-surface-area parts.

- Mineral-Filled Nylons: Primarily found in SLS, these provide enhanced heat deflection temperatures (HDT) for high-heat environments like engine bays.

Specialty Powders: Carbon Fiber, Alumide, and Flame-Retardant (FR) Grades

The true strength of SLS lies in its ability to process complex composite blends. For aerospace and electronics applications, material certification is non-negotiable. If your part requires UL94 V-0 ratings or metallic-infusion, SLS is the only viable path.

Carbon-filled powders provide a high strength-to-weight ratio that MJF currently struggles to match in sheer stiffness. Furthermore, Alumide (aluminum-filled nylon) allows for the production of parts with a metallic appearance and enhanced thermal conductivity, essential for specialized heat sinks and decorative industrial housings.

TPU and Elastomers: Achieving Shore A Hardness with Powder Bed Fusion

Both MJF and SLS have made significant strides in flexible materials, with Thermoplastic Polyurethane (TPU) being the primary elastomer of choice. These “rubber-like” materials are essential for gaskets, seals, and wearable medical devices.

However, the fusion mechanism matters for performance. MJF TPU is generally more airtight and watertight because the fusing agents create a more continuous solid boundary compared to laser paths.

SLS TPU offers excellent flexibility but may remain slightly porous, making it better for breathable structures or protective lattices where fluid containment is not the primary objective.

Surface Quality & Post-Processing

The aesthetic “out of the machine” differs sharply between these two technologies. SLS parts typically exhibit a grainy, “sugar cube” texture due to the way the laser melts the outer boundary of the powder particles.

Conversely, MJF yields a denser, “matte stone” finish. Because MJF uses liquid agents to define the part boundaries, the surface is naturally more uniform and less porous, providing a more professional baseline for consumer-facing components.

Detailing Agents vs Lasers: Fine Feature Resolution Limits

The primary advantage of MJF is its ability to maintain sharper edges and finer details. While a laser has a fixed beam diameter that can cause “heat bleed,” MJF utilizes a chilling detailing agent around the part’s perimeter.

This agent evaporates and absorbs heat, preventing the fusion of surrounding “unprinted” powder. This thermal control allows for reliable 0.5mm wall thicknesses and crisp vertical features that SLS often struggles to replicate without rounded edges or dimensional blooming.

Vapor Smoothing and Media Blasting: Achieving “Injection Molded” Finishes

To reach consumer-grade standards, post-processing is mandatory. Media blasting is the first step, removing excess powder to reveal the raw finish. However, Vapor Smoothing (chemical polishing) is the gold standard for “injection molded” quality.

This process uses a vaporized solvent to partially melt the part’s surface, sealing pores and creating a glossy, waterproof finish. This is critical for medical components requiring sterilization and consumer electronics where a high-end tactile feel is non-negotiable for market success.

The Color Conflict: Why MJF is Gray/Black while SLS is White/Versatile

The aesthetic versatility of these processes is dictated by their thermal catalysts. MJF parts are natively gray/black because the fusing agent is carbon-based to maximize infrared heat absorption. While parts can be dyed deep black for a sleek, industrial look, they cannot be colored with light or vibrant hues.

In contrast, SLS parts are naturally white, as the laser does not require a dark ink to initiate fusion. This provides a “blank canvas” for post-processing. In 2026, SLS remains the superior choice for branded consumer goods and medical devices that require specific RAL color matching or bright, multi-colored finishes.

Production Economics: Throughput, Speed, and Unit Cost

In 2026, shifting from a “price-per-build” to a “unit cost at scale” mindset is essential for manufacturing profitability. While both processes eliminate expensive tooling, their fiscal profiles diverge as volumes increase.

Procurement officers must evaluate total cost of ownership (TCO), factoring in build density and machine uptime. MJF often provides a lower cost-per-part for serialized production, whereas SLS remains financially viable for low-volume, highly complex geometries where specialized material properties justify a higher price premium.

Batch Efficiency: How MJF’s Linear Fusion Outpaces Point-to-Point Lasers

The fundamental difference in speed lies in the fusion mechanism. Think of SLS as a “Pen”; the laser must physically trace the geometry of every part, meaning as you add more components to the build, the time and cost increases linearly.

MJF operates like a “Scanner.” The print heads move across the entire build bed in a single pass, fusing all parts in that layer simultaneously regardless of their complexity or quantity. Consequently, a full build chamber in MJF takes the same amount of time to print as a single part.

This fixed build time allows for massive throughput advantages. For production runs, MJF can deliver hundreds of functional components in the same window it takes SLS to finish a fraction of that volume, making it the superior engine for bridge-to-manufacturing applications.

Cooling & Turnaround: The Impact of Removable Build Chambers on Lead Times

Total lead time is often bottlenecked by thermal management rather than the print speed itself. Powder bed fusion requires a slow cooling period to prevent warping and internal stress.

MJF systems often utilize removable build units, allowing the printer to begin a new job immediately while the previous batch cools in a separate “Fast Cooling” station. This can shave up to 24 hours off the total production cycle, doubling the machine’s daily output.

Traditional SLS machines often require the part cake to cool inside the printer, leading to significant equipment downtime. For time-sensitive industrial projects, the ability to hot-swap build chambers makes MJF the faster path from CAD file to finished assembly.

Total Cost of Ownership (TCO): Hidden Costs of Fusing Agents vs Laser Power

Calculating the Total Cost of Ownership (TCO) requires looking beyond the raw powder price. SLS systems primarily incur costs from high-wattage CO2 laser consumption and specialized nitrogen environments, but they lack the recurring “consumable” expense of liquid agents.

In contrast, MJF requires a continuous supply of fusing and detailing agents, which can account for up to 25–30% of the part cost. However, MJF offsets this with a significantly lower energy cost per part due to its high-speed throughput.

When evaluating TCO for production, engineers must bold the fact that MJF’s 80% powder recyclability typically outweighs the cost of agents for large batches. Conversely, for sporadic, low-volume runs, the absence of expensive proprietary agents makes SLS the more predictable financial choice.

Designing for Powder Bed Fusion (DfAM)

Successful production requires shifting from subtractive mindsets to Design for Additive Manufacturing (DfAM). To minimize unit costs, you must optimize for build density and powder evacuation.

Failure to respect thermal thresholds leads to warping and dimensional inaccuracy. Follow these rigid technical constraints to ensure your parts survive the fusion process without compromising structural integrity or requiring expensive manual rework.

Minimum Wall Thickness & Hole Diameters: MJF vs SLS Specs

Precision is governed by the thermal “bloom” of the heat source. MJF offers tighter tolerances for fine features due to its liquid cooling agents, while SLS provides better stability for larger, thicker geometries. Use these thresholds as your hard design limits.

| Feature | MJF Specification | SLS Specification |

| Min Wall Thickness | 0.50 mm | 0.80 mm |

| Min Hole Diameter | 0.50 mm | 1.00 mm |

| Clearance (Moving Parts) | 0.40 mm | 0.50 mm |

| Tolerance (Standard) | ±0.2 mm or ±0.2% | ±0.3 mm or ±0.3% |

Managing Thermal Stress: Preventing Warping in Flat, Thin Geometries

Thermal management is the primary challenge in powder bed fusion. Large, flat, or thin-walled surfaces are highly susceptible to thermal curling as layers cool and contract. To mitigate this, engineers must avoid placing large footprints parallel to the build plate.

In MJF, the high thermal energy of infrared lamps can cause warping in parts with non-uniform thickness. We recommend maintaining constant wall ratios and using ribbing or gussets to provide structural rigidity.

For SLS, the point-to-point laser heat can create “cold spots,” so parts should be positioned in the center of the build cake where thermal stability is highest to ensure dimensional accuracy.

Hollowing & Nesting Rules for Maximum Build Density

- Internal Hollowing: Convert solid volumes into shells to reduce material consumption. A 2.0 mm to 3.0 mm wall thickness is generally sufficient for structural housings.

- Escape Holes: Every hollow part must include at least two 3.0 mm escape holes to allow un-fused powder to be removed during post-processing.

- Volumetric Nesting: Unlike FDM, these technologies do not require supports. You can “stack” parts in 3D space. Aim for a 10%–12% nesting density for MJF and 8%–10% for SLS to avoid overheating.

- Orientation for Success: Orient large flat surfaces at a 20-degree angle to the build plate to prevent “stair-stepping” and thermal curling.

- Cost Efficiency: Implementing these rules typically results in a 30% reduction in per-unit cost by maximizing the number of parts per build cycle.

Sustainability & Circularity: The Green Manufacturing Mandate

By 2026, industrial procurement is no longer driven solely by cost; ESG (Environmental, Social, and Governance) compliance is now a mandatory metric. Leading manufacturers are transitioning toward “Closed-Loop” additive systems to eliminate the historical waste associated with plastic fabrication.

The shift to powder bed fusion over traditional injection molding allows for Zero-Waste nesting, but the true environmental differentiator lies in the chemical stability of the unused powder. High-performance organizations now prioritize MJF for large-scale production due to its superior material longevity and lower carbon footprint per finished kilogram.

Powder Refresh Ratios: MJF’s 80% Reuse vs SLS’s 50% Baseline

The most significant operational waste in 3D printing is “Powder Aging,” where un-fused material degrades due to prolonged heat exposure. In traditional SLS, the high-intensity laser heat damages surrounding particles, typically requiring a 50/50 mix of new and used powder to maintain part quality.

In contrast, MJF’s controlled infrared fusion is much gentler on the surrounding bed. MJF requires only 20% fresh powder to maintain peak mechanical properties, allowing for an 80% reuse rate. This efficiency drastically reduces landfill contributions and provides a more sustainable pathway for high-volume manufacturing while lowering the long-term material overhead.

Carbon Footprint: Energy Consumption per Kilogram of Finished Part

Quantifying the carbon footprint of additive manufacturing requires an analysis of energy-to-output ratios. MJF systems are recognized for having a lower energy consumption per kilogram of finished parts during high-density builds.

Because MJF fuses entire layers in seconds, the machine’s heaters and lamps run for a shorter total duration compared to the prolonged laser-firing cycles of SLS. When machines are fully “nested” with parts, MJF’s energy efficiency makes it the more eco-conscious choice for industrial production runs, whereas SLS energy costs remain higher due to the extended time required for the laser to trace every individual geometry.

Bio-Based Feedstocks: The Rise of Castor-Oil Derived PA11

As petroleum-based plastics face increased regulation, Polyamide 11 (PA11) has emerged as the sustainable “gold standard.” Unlike PA12, which is oil-derived, PA11 is a 100% bio-based polymer sourced from castor oil beans.

This renewable feedstock offers a significantly lower carbon footprint and is compatible with both MJF and SLS systems. Beyond its green credentials, PA11 provides superior ductility and impact resistance, proving that sustainable material choices do not require a sacrifice in mechanical performance for aerospace or medical applications.

Industry Use Cases: Choosing by Application

Selecting between these technologies requires matching the process to the specific regulatory and mechanical environment. While MJF dominates in serialized production, SLS remains the anchor for certified aerospace materials and specialized industrial hardware. Use these sector-specific directives to align your technology choice with industry standards.

Automotive & Aerospace: Durable Connectors and Lightweight Ducts

- Under-the-Hood Components: We recommend MJF for fluid manifolds and electrical connectors due to its superior airtightness and resistance to engine vibrations.

- Ducting & Air Handling: MJF is the standard for HVAC ducting, providing the high-pressure seals and thin-wall durability required for lightweight automotive assemblies.

- Specialized Aerospace Brackets: SLS is preferred for load-bearing aerospace hardware when using Carbon-Filled or Flame-Retardant (FR) nylons to meet strict FAA “Fire, Smoke, and Toxicity” (FST) regulations.

- Weight Reduction: Both technologies enable topology optimization, allowing engineers to replace heavy aluminum castings with high-strength, glass-filled polymer lattices.

Medical & Healthcare: Orthotics, Prosthetics, and Skin-Safe Parts

- Custom Orthotics: MJF is the leading choice for orthotic insoles and braces because its isotropic strength handles the multi-directional stresses of human gait without failing.

- Prosthetic Limbs: Engineers utilize PA11 for its exceptional impact resistance and durability in high-wear prosthetic sockets.

- Biocompatibility: Both systems utilize PA11 and PA12, which are certified for long-term skin contact and comply with ISO 10993 standards.

- Surgical Guides: SLS is often favored for sterilizable surgical guides due to its material stability during high-temperature autoclave cycles.

Consumer Electronics: Enclosures and Personalized Gear

- Protective Enclosures: We recommend MJF for smartphone cases and laptop housings due to its superior impact resistance and tighter dimensional tolerances for snap-fit assemblies.

- Wearable Technology: MJF’s ability to print TPU structures makes it the standard for fitness tracker bands.

- Custom Aesthetics: SLS is the preferred choice for personalized gaming peripherals and designer headphones where vibrant color-matching or pure white finishes are required for market appeal.

- Tactile Quality: For high-touch surfaces, MJF combined with vapor smoothing provides a premium, non-porous feel that mimics the quality of mass-produced injection-molded consumer goods.

Conclusion: Making Your Final Selection

Choosing between MJF vs SLS requires an objective evaluation of your part’s final environment. Before finalizing your procurement order, run your project through this technical checklist to ensure the technology matches your operational goals:

- Is the part load-bearing? If you require uniform strength in the Z-axis to prevent delamination, select MJF.

- Are you printing more than 50 units? If throughput and lower unit costs are the priority, select MJF.

- Does the part require a specific color? If you need anything other than black or gray, select SLS.

- Do you need specialty materials? For carbon-fiber reinforcement or UL94 V-0 flame retardancy, select SLS.

- Is sustainability a KPI? If maximizing powder recyclability (up to 80%) is required for ESG compliance, select MJF.

FAQs

Which is stronger: MJF or SLS?

While both have similar peak tensile strengths (~48 MPa for PA12), MJF is stronger in the Z-axis (up to 95% of XY strength), whereas SLS often suffers from Z-axis weakness.

Is MJF cheaper than SLS for large production runs?

Yes. For batches exceeding 50–100 units, MJF is typically 15–30% more cost-effective due to its ability to print entire layers at once and its 80% powder recyclability compared to SLS’s 30–50%.

What is the minimum wall thickness for MJF vs SLS?

The standard recommendation is 0.5mm for MJF and 0.8mm for SLS, though structural features should ideally maintain 1.0mm–2.0mm for reliability.

Can SLS parts be dyed any color?

Yes, because SLS parts are naturally white, they can be dyed almost any color. MJF parts are naturally gray/black and can only be dyed darker colors or black.

Is MJF or SLS better for medical-grade parts?

Both are viable, but MJF PA12 is frequently highlighted for its ISO 10993 and USP Class I-IV certifications, making it a leader for skin-safe orthotics and prosthetics.