Nylon 11 vs. 12: The Engineer’s Guide to Performance, Cost, and Sustainability

Executive Summary: 10-Second Decision Matrix

Selecting between Nylon 11 and Nylon 12 requires balancing mechanical ductility against long-term dimensional stability. While both polyamides offer excellent chemical resistance, their molecular structures dictate drastically different behaviors in high-moisture environments and sub-zero impact scenarios.

| Property | Nylon 11 (PA11) | Nylon 12 (PA12) |

| Density | 1.03 g/cm³ | 1.01 g/cm³ |

| Melting Point | ~200°C (Higher heat resistance) | ~178°C |

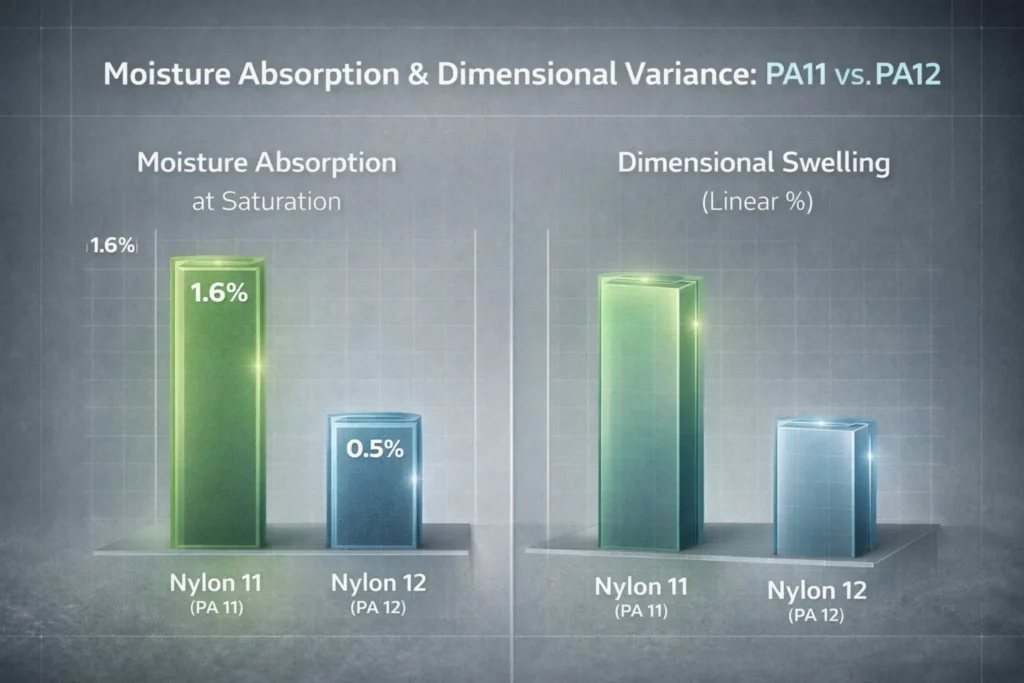

| Moisture Absorption | ~1.6% (Saturation) | ~0.5% (Saturation) |

| Impact Resistance | Superior (No-break at -40°C) | Good (Becomes brittle <0°C) |

| Primary Use Case | Living hinges, fuel lines, impact clips | Precision gears, housings, connectors |

When Nylon 11 Is the Better Choice

Specify PA11 for dynamic components requiring high elastic recovery and fatigue resistance.

Deploy in sub-zero environments where impact strength must be maintained without brittle failure.

Select for high-flex applications like living hinges or snap-fits where elongation at break is a critical KPI.

Utilize in high-vibration systems needing inherent damping properties to prevent stress cracking.

Prioritize for ESG-mandated projects as it is a 100% bio-based polymer derived from castor oil.

When Nylon 12 Makes More Sense

Standardize on PA12 for interlocking assemblies where 0.5% moisture absorption is the maximum allowable limit for fitment.

Choose for high-precision housings where dimensional drift must be minimized across varying humidity levels.

Optimize for high-volume injection molding due to its lower melting point, which reduces energy consumption and cycle times.

Use in dry environment electronics where higher stiffness (Tensile Modulus) is required over ductility.

Leverage for supply chain security as PA12 has a broader global manufacturer base compared to the specialty nature of PA11.

The Science of One Carbon Atom: Why 11 ≠ 12

The performance gap between Nylon 11 and Nylon 12 stems from a single methylene group. While both are long-chain polyamides, the 11-carbon repeat unit in PA11 creates a higher amide group density than PA12’s 12-carbon chain.

This higher density increases the polar sites available for hydrogen bonding. Consequently, PA11 exhibits a higher affinity for water, reaching 1.6% moisture absorption at saturation compared to 0.5% for PA12.

For the designer, this molecular shift represents a fundamental trade-off: PA11 prioritizes ductility and energy absorption, while PA12 prioritize stability and hydrolytic resistance.

Molecular Structure & Density Comparisons

Although both are semi crystalline, chain length dictates packing efficiency. PA11 has a density of 1.03 g/cm³, whereas PA12 averages ~1.01 g/cm³. This tighter packing in PA11 correlates with higher crystallinity, which directly influences its superior impact strength at low temperatures.

Engineering Risk: If your assembly requires interlocking tolerances tighter than ±0.05mm, the lower density and amide concentration of PA12 provide the necessary insurance against moisture-induced swelling that can seize moving parts in PA11.

The Bio-Based Reality: Castor Beans vs. Petroleum

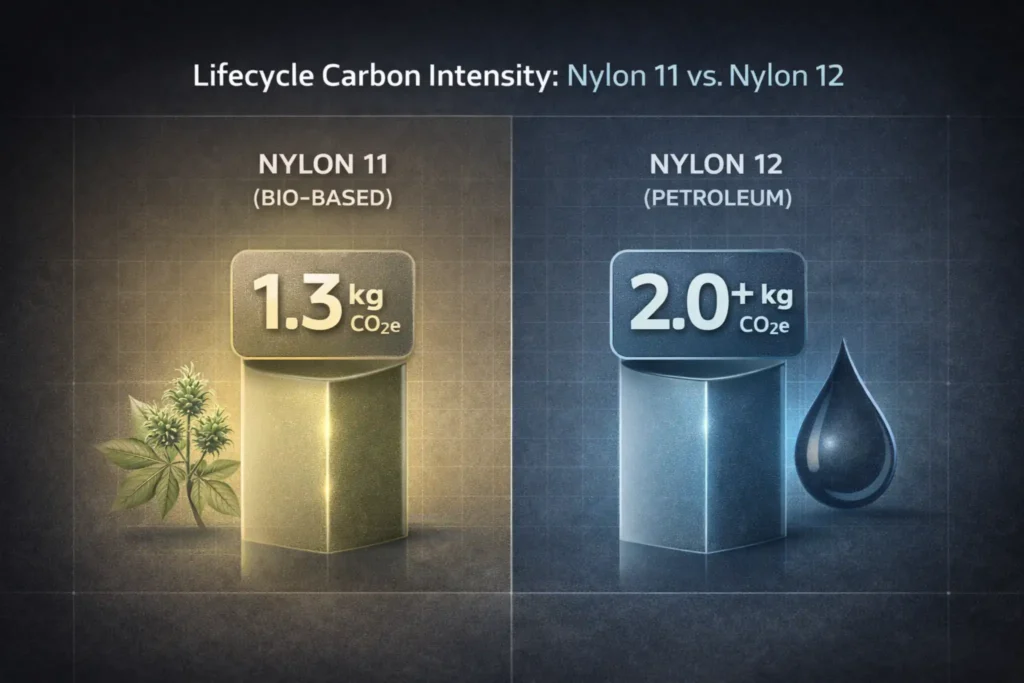

The origin of the polymer is no longer just a “green” perk; it is a procurement requirement for ESG-compliant supply chains.

- Nylon 11: Derived from castor oil (Ricinus communis), a non-food crop. It is 100% renewable and offers a significantly lower carbon footprint (CO2e/kg) than its petroleum counterparts.

- Nylon 12: Primarily synthesized from petrochemical butadiene. While it offers higher industrial scalability and lower cost, it carries a higher fossil-carbon debt.

Decision Threshold: Specify PA11 when Scope 3 emission targets or renewable content mandates are critical KPIs for the end product.

Moisture Absorption: The Critical Performance Gap

In precision engineering, moisture uptake is a primary failure mode, not a secondary property. Nylon 11 reaches ~1.6% saturation, whereas Nylon 12 levels off at ~0.5%. This 3x difference dictates the material’s modulus drift and dimensional predictably over the product lifecycle.

Engineering Directive: Assume PA11 will undergo significant “conditioning” shifts unless the environment is hermetically controlled.

Specify PA12 for assemblies where the part must mate, seal, or index with the same tolerance on Day 500 as Day 1.

Why Nylon 12 Excels in Humid Environments

PA12’s resistance to water-driven property drift makes it the industrial standard for hydrolytic stability. Because saturation is capped at 0.5%, the dimensional variance is negligible across global shipping and storage cycles.

- Interlocking Assemblies: PA12 prevents “binding” in sliding fits and gears.

- Sealed Housings: Minimal swelling ensures gasket compression remains within the calculated elastic range.

- Operational Risk: In high-humidity regions, PA11 can lose up to 30% of its dry tensile modulus, a risk PA12 effectively mitigates.

Dimensional Stability in Precision Engineering

Moisture acts as a plasticizer in Nylon 11, infiltrating amorphous regions and reducing intermolecular bonding. While this increases impact toughness (making “wet” PA11 nearly impossible to crack), it compromises precision.

- The Modulus Trade-off: As PA11 absorbs water, it becomes more ductile but less stiff.

- Design Rule: If using PA11, you must calculate dimensions based on the equilibrated (wet) state.

- Tolerance Chains: Avoid PA11 in stacked tolerance chains where cumulative swelling of ±0.1% per part can lead to total assembly failure.

Mechanical & Thermal Limits

For material selection, the trade-off is clear: PA11 provides ductility and impact survivability, while PA12 provides stiffness and dimensional control.

Engineers must validate these values against the equilibrated (wet) state, as moisture will shift these benchmarks.

| Property (Typical Unfilled) | Nylon 11 (PA11) | Nylon 12 (PA12) |

| Tensile Modulus | 1200–1500 MPa | 1400–1800 MPa (Stiffer) |

| Elongation at Break | 200–350% (Ductile) | 50–200% |

| Notched Izod Impact | Superior (especially <0°C) | Moderate (Brittle risk) |

| Melting Point (Tm) | 185–200°C | 175–180°C |

| HDT (at 0.45 MPa) | ~140°C | ~135°C |

Impact Resistance & Elongation: The PA11 Advantage

If the primary failure mode is fracture or flex-fatigue, PA11 is the technically superior choice. With elongation at break often exceeding 300%, PA11 dissipates energy through deformation rather than crack propagation.

- The PA12 Stiff-Point: PA12 offers a higher tensile modulus (up to 1800 MPa). It deflects less under load, making it the standard for precision housings that must remain rigid.

- Cold-Weather Performance: Specify Nylon 11 for outdoor or aerospace components exposed to -40°C. PA12 becomes significantly more brittle at these temperatures, increasing the risk of catastrophic failure under vibration.

Continuous Service Temperatures & Heat Deflection

While PA11 has a higher melting point, neither material is a “high-heat” solution. For both polyamides, 120°C is the practical limit for sustained service under load.

- The Melting Point Trap: Do not use the 200°C melting point of PA11 as a proxy for heat resistance. Above 120°C, both materials suffer from creep and accelerated modulus loss.

- Design Rule: Use melting points strictly for processing calibration (injection molding/3D printing). For long-term reliability, ensure your operational window remains below 100°C for continuous mechanical stress to prevent permanent deformation.

Manufacturing Behavior: 3D Printing & Injection Molding

Manufacturing feasibility is often the deciding factor between these polyamides.

Standardize on PA12 for high-volume repeatability; it exhibits superior melt stability and more predictable post-mold cooling.

Specify PA11 for functional prototypes where ductile failure is a requirement, but account for its ±0.2% higher shrinkage rate during mold design.

SLS vs. MJF Optimization

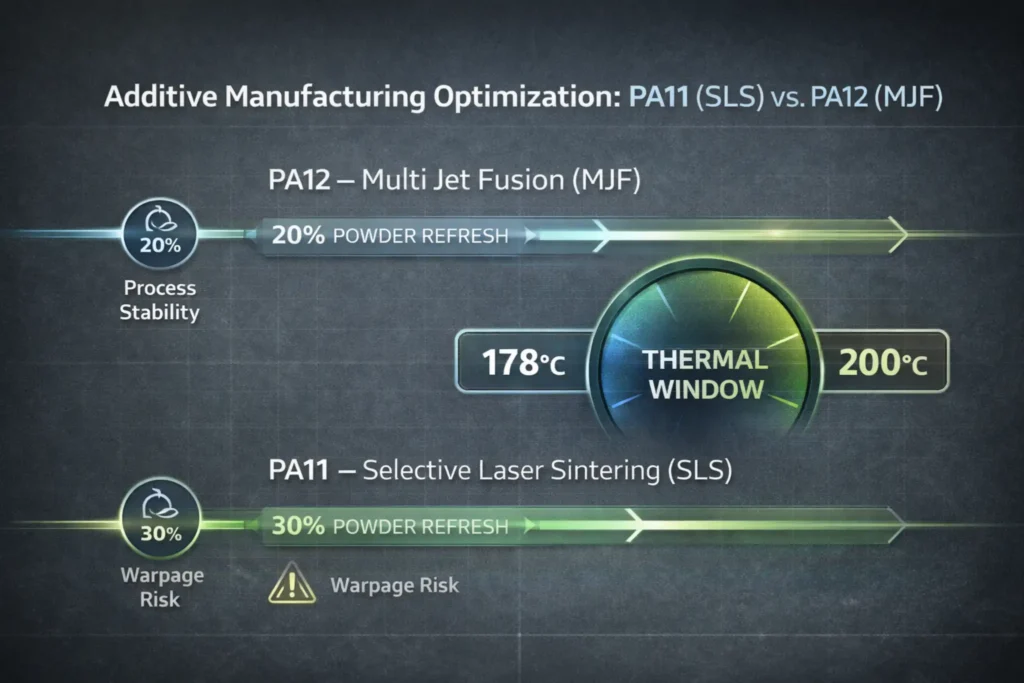

In powder-bed fusion, the material ecosystem dictates the total cost of ownership.

HP Multi Jet Fusion (MJF) is architected for Nylon 12, offering a stable thermal window and consistent isotropic properties.

Selective Laser Sintering (SLS) is the preferred platform for Nylon 11, specifically for parts requiring living hinges or impact-rated housings.

- Powder Refresh Economics: PA12 workflows typically maintain consistency at a 20% refresh rate. Conversely, PA11 often requires a 30–35% refresh rate to prevent “orange peel” surface defects and mechanical degradation.

- Production Velocity: PA12 provides a wider processing window, reducing the risk of “cake” breakouts and ensuring higher yield in multi-part builds.

Wall Thickness & Design Freedom

Design constraints diverge based on the material’s crystallization behavior. Nylon 12 offers lower, more isotropic shrinkage, enabling tighter tolerance stacks in complex assemblies.

- Minimum Wall Thresholds: High-resolution MJF allows for 0.8mm walls in PA12, whereas PA11 often requires 1.0mm to mitigate the risk of moisture-induced warpage during the cooling phase.

- The Warpage Risk: PA11 is significantly more sensitive to uneven cross-sections. If your geometry includes long, thin spans, implement ribs or gussets to counteract post-processing distortion.

- Molding Precision: Because PA12 is less sensitive to moisture, it holds ±0.05mm tolerances across global production sites more reliably than PA11, which can fluctuate based on local factory humidity.

Sustainability & ESG Compliance

Material selection is a primary lever for Scope 3 emissions reductions. Audits now prioritize feedstock origin and material circularity.

Specify Nylon 11 (PA11) to meet renewable content mandates; its derivation from castor beans (a non-food crop) offers a transparent, bio-based narrative.

Standardize on Nylon 12 (PA12) only when its lower processing energy and higher manufacturing yield result in a lower total lifecycle carbon debt.

Carbon Footprint Analysis

The carbon intensity of PA11 is significantly lower than petroleum-derived PA12. On average, PA11 resins offer a ~40% reduction in CO2e/kg compared to fossil-based polyamides.

- Renewable Origin: PA11 is 100% bio-based (ISO 16620), derived from the Ricinus communis plant.

- Sequestration: Document the carbon sequestration of the castor crop in your ESG reports to offset manufacturing emissions.

- Lifecycle Reality: A “bio-based” label is insufficient; you must provide the specific Life Cycle Assessment (LCA) data to satisfy carbon-border adjustment taxes.

Recyclability & Powder Refresh Rates

In Additive Manufacturing (AM), sustainability is measured by powder waste mitigation. Excess powder disposal is increasingly viewed as an avoidable emission by ESG auditors.

- Refresh Strategy: PA12 maintains a competitive edge with a consistent 20% refresh rate, minimizing waste in high-volume MJF or SLS production.

- Waste Risk: PA11 typically requires a 30% refresh rate to prevent mechanical degradation. Mitigate this by implementing a closed-loop recycling program or using “virgin-free” sustainable grades now entering the 2026 market.

- Circular Economy: Both materials are thermoplastic, meaning they are 100% recyclable. However, infrastructure for post-industrial Nylon 11 is currently more specialized due to its smaller market share.

Market Reality: Cost, Lead Times, and Producers

In 2026, procurement for polyamides is driven by supply chain resilience and producer concentration.

Standardize on PA12 for high-volume enterprise sourcing; its broad industrialization and multiple global production sites ensure faster lead-time recovery.

Specify PA11 for performance-critical or ESG-mandated programs, but account for its higher supply risk due to limited monomer pathways.

The 30% Price Premium: Is PA11 Worth It?

Expect a 20–30% price premium for PA11 compared to equivalent PA12 grades. This cost gap is a structural reality of the bio-based castor oil feedstock and specialized refining processes.

- Financial Justification: Only authorize the PA11 premium if it eliminates catastrophic failure risk (e.g., flex-fatigue in sub-zero environments) or if your organization requires 100% bio-based content for regulatory compliance.

- PA12 Economics: PA12 benefits from massive petrochemical integration, offering superior cost stability and lower price volatility during global shipping disruptions.

Global Supply Chain & Producer Monopoly

Understanding the manufacturer landscape is critical for second-sourcing and risk management.

- Nylon 11 (PA11): Primarily a specialty market dominated by Arkema (Rilsan®). While Arkema has expanded capacity in 2024-2025, PA11 remains a single-source risk for many large-scale programs.

- Nylon 12 (PA12): Features a more robust supply base. Evonik is the global leader (VESTAMID®/VESTOSINT®), but competition from EMS-GRIVORY, Ube, and Arkema provides better leverage for procurement teams during contract negotiations.

- Directive: For programs exceeding 50,000 units annually, prioritize PA12 unless the mechanical requirements of PA11 are non-negotiable.

Final Verdict: Application-Specific Recommendations

Use these verdicts as your engineering shortcut.

Nylon 11 is the durability-first choice when shock, flex, cold, and vibration are the primary failure risks.

Nylon 12 is the precision-first choice when tight tolerances, repeatable fit, and scalable production dominate the cost of quality.

Decision Rule: If your part is a dynamic system (moving, flexing, vibrating), PA11 earns its price premium. If your part is a geometric system (mating, sealing, meshing), PA12 prevents the need for expensive rework.

Automotive & Aerospace

- Fuel Lines & Underbody Exposure: Specify PA11 for long-term vibration resistance and superior zinc chloride resistance in road-salt environments.

- Electrical Connectors & Sensor Housings: Standardize on PA12 where dimensional repeatability ensures high assembly yields across global production sites.

- Cold-Zone Structural Parts: Deploy PA11 when brittle failure risk at -40°C is unacceptable.

Medical & Consumer Goods

- Wearables & Orthotics: Choose PA11 for its skin-contact history, superior ductility, and impact resilience.

- Rigid Device Housings: Default to PA12 for predictable snap-fit assembly and low moisture-driven drift.

- Sustainability-Driven SKUs: Prioritize PA11 to satisfy 2026 renewable content mandates and Scope 3 emission targets.

Industrial & Fluid Handling

- Pneumatic Lines & Tubing: Select PA12 for consistent wall thickness and long-term burst pressure stability in dry environments.

- Dynamic Abrasion Environments: Utilize PA11 for its high fatigue life and resistance to surface wear under repeated motion.

- Sealed Manifolds: Specify PA12 to maintain critical o-ring compression and prevent moisture-induced swelling that leads to leaks.

FAQs

Which material is safer for medical applications and skin contact?

Both are generally considered skin-safe and biocompatible for external use, such as prosthetics and orthotics. However, Nylon 12 is more frequently certified for food-contact and specialized medical devices like cardiac catheters due to its lower permeability and higher dimensional stability.

Always verify the specific FDA or ISO 10993 certification with your material supplier.

Why is Nylon 11 more expensive than Nylon 12?

PA11 typically carries a 20–30% price premium. This is due to the limited global production of the castor bean feedstock and the fact that Arkema remains the primary producer of the monomer.

PA12 has a more diverse supply chain with multiple global manufacturers, including Evonik, which drives more competitive pricing for high-volume production.

Which nylon has better UV resistance for outdoor use?

Nylon 11 is the superior choice for outdoor longevity. It has inherently better UV stability and weathering resistance compared to PA12. While both can be stabilized with carbon black, PA11 is less likely to undergo surface degradation or “chalking” after 10+ years of exposure to sunlight and ozone.

Is Nylon 11 really “better” for the environment?

Yes, from a feedstock perspective. PA11 is 100% bio-based, derived from renewable castor oil, whereas PA12 is synthesized from petroleum-based butadiene. Using PA11 typically reduces your Scope 3 carbon footprint by ~40% compared to petroleum-derived polyamides.