Nylon 6 6 (PA66): Properties, Performance Limits, and Use Cases

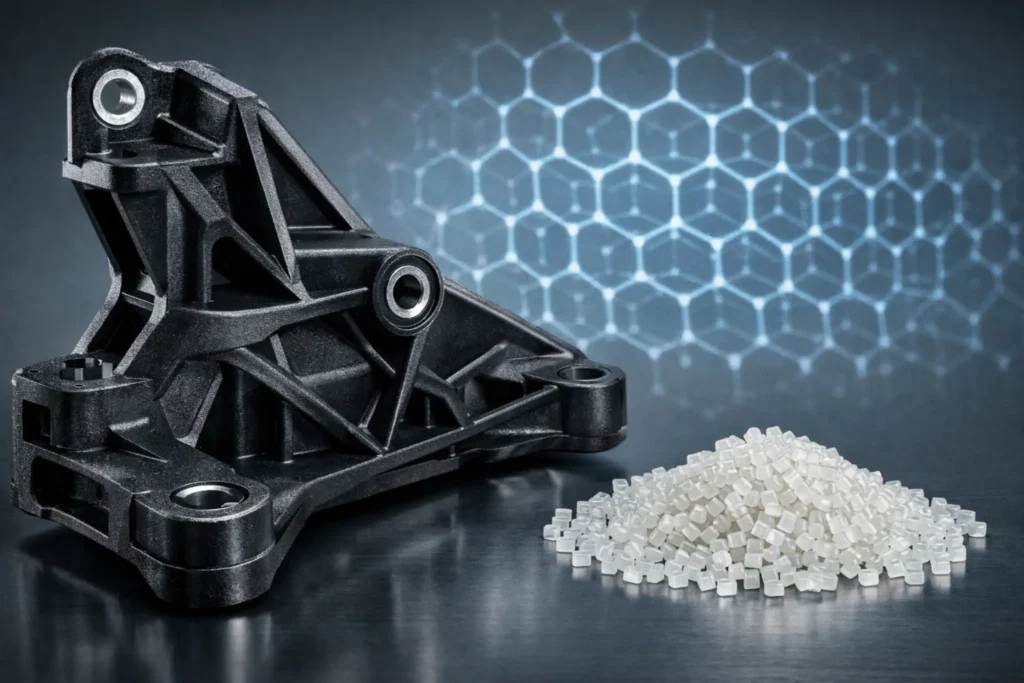

Nylon 6 6 (PA66) delivers the thermal stability and mechanical rigidity required for components operating under high-load and elevated-temperature environments.

This high-performance thermoplastic provides superior abrasion resistance and stiffness compared to PA6 or commodity resins.

Engineers specify PA66 for structural automotive, industrial, and electrical applications where thermal deflection and fatigue endurance are non-negotiable.

Quick Verdict — Is Nylon 6 6 the Right Material for Your Application?

When Nylon 6 6 Is the Best Choice

- Fatigue endurance: Specify PA66 for high-cycle components such as gears, bushings, and actuator parts under continuous loading.

- Heat resistance: Use PA66 in under-hood EV thermal management brackets and motor-adjacent housings where plastics must retain stiffness.

- Structural rigidity: Choose glass-filled PA66 for structural brackets, mounts, and load-bearing frames that must resist creep.

- Wear performance: Select PA66 for sliding interfaces where abrasion resistance limits material loss over time.

- Dimensional strength: Apply PA66 where higher stiffness than PA6 supports tighter mechanical alignment.

When You Should Avoid Nylon 6 6

- Moisture-driven tolerance shift: Avoid PA66 in precision assemblies where water absorption changes dimensions and causes misalignment.

- Submerged service: Do not use PA66 for long-term immersion where swelling and hydrolysis reduce strength.

- Strong acid exposure: Reject PA66 in contact with strong acids or aggressive chemical baths that attack polyamide bonds.

- Critical electrical stability: Avoid PA66 in dielectric-critical parts exposed to humidity cycling unless fully conditioned and tested.

- Low-cost commodity targets: Skip PA66 when PP, PBT, or PA6 meets performance needs at significantly lower total cost.

Nylon 6 6 Material Overview (What Actually Matters)

Chemical Structure & Polymer Behavior

Nylon 6 6 forms from symmetrical 6-carbon monomers (hexamethylenediamine + adipic acid), which align predictably along the polymer chain. That symmetry maximizes interchain hydrogen bonding between amide groups and drives higher crystallinity than PA6.

This tighter crystalline matrix increases stiffness, raises heat resistance, and improves fatigue endurance.

PA66 also shows lower chain mobility than PA6, so it resists creep more effectively in warm, stressed environments exactly where softer nylons relax and distort. This structural rigidity results in a sharp, predictable melting point that simplifies thermal processing but requires precise temperature control.

Key Mechanical Properties at a Glance

| Property | Value (Metric) | Why it Matters to the Designer |

| Density | ~1.14 g/cm³ | Defines part weight and dictates sink/packing behavior during molding cycles. |

| Tensile Strength | ~80 MPa (unfilled) | Sets the baseline load capacity before yield; crucial for calculating safety factors. |

| Flexural Modulus | ~2.8–3.2 GPa (unfilled) | Predicts stiffness, deflection control, and creep resistance under long-term load. |

Mechanical Performance Under Real Conditions

Tensile Strength, Stiffness, and Fatigue Resistance

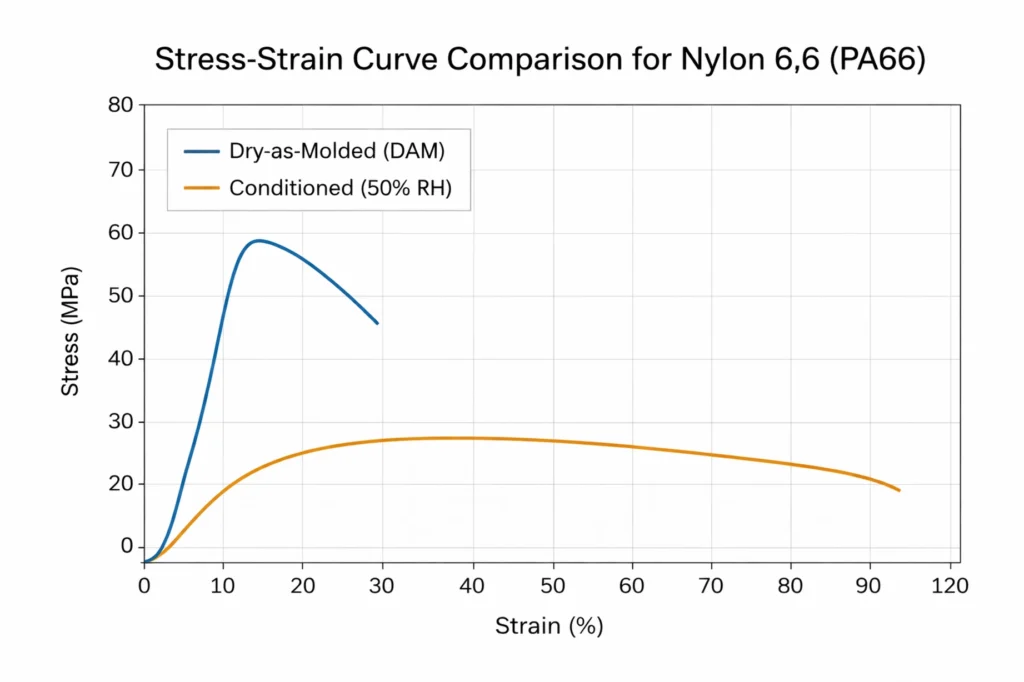

Treat moisture state as a design variable, not a footnote. Dry-as-Molded (DAM) PA66 delivers the highest tensile strength and flexural stiffness because water has not yet plasticized the polymer matrix. Specify DAM data when parts must hold precision alignment or resist tooth deflection immediately after molding.

Expect a measurable drop in stiffness once PA66 reaches Conditioned (50% RH) equilibrium. Water molecules disrupt interchain hydrogen bonding, which increases chain mobility and impact toughness but reduces modulus and tensile strength. Use conditioned data for real-world housings, brackets, and clips operating in ambient humidity.

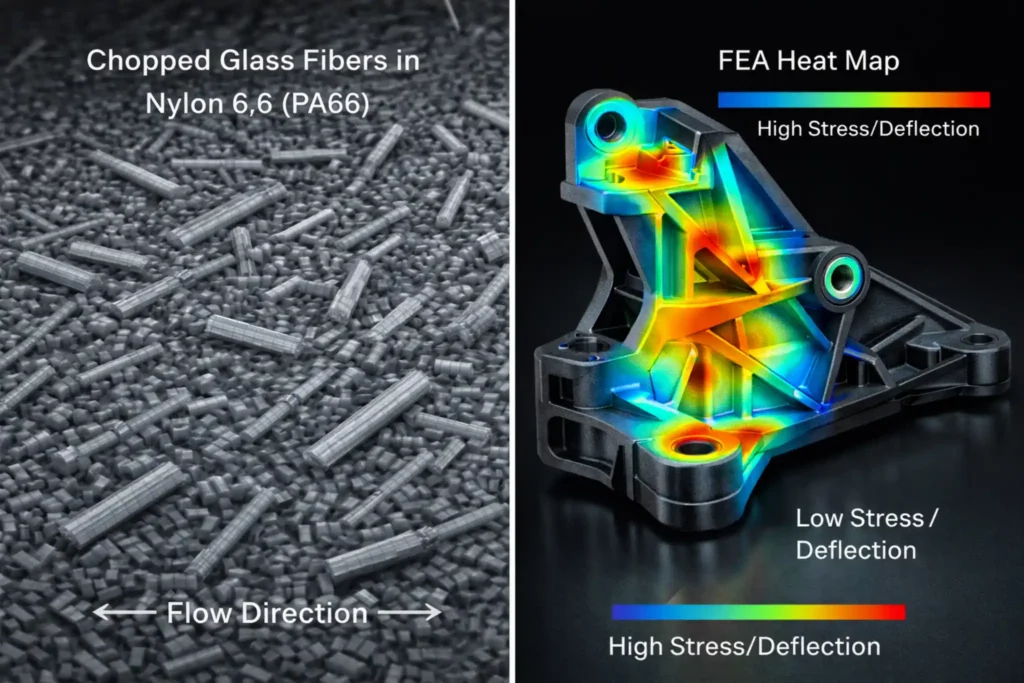

For fatigue endurance, PA66 performs best when designers control stress amplitude and heat buildup. Select glass-filled grades for cyclic structural loading and validate with fatigue curves that match the target moisture state.

Creep Resistance Under Long-Term Load

Designers must account for time-dependent deformation, especially in warm assemblies carrying constant stress. PA66 resists creep more effectively than polyolefins because its hydrogen-bonded crystalline network limits chain slippage under load.

That advantage remains strongest in reinforced grades and DAM states. However, creep accelerates significantly with heat and moisture. Use specific creep curves at service temperature, apply generous safety factors for snap fits and fastener bosses, and avoid designing at the edge of allowable strain limits.

Chemical Resistance Limits (Fuel, Oils, Salts, and Solvents)

- Fuels & Hydrocarbons (Strong): Gasoline, diesel, and lubricating oils show minimal impact. PA66 maintains strength and dimensional stability in typical automotive exposures.

- Oils & Glycols (Strong): Engine greases and oils cause low swelling. For glycol-based coolants, confirm additive package compatibility at high temperatures.

- Salts & Road Brine (Moderate): Sodium chloride is typically acceptable, but monitor for surface stress cracking in highly stressed components.

- Major Red Flags (Avoid):

- Zinc Chloride: Aggressively attacks the polyamide matrix; causes rapid stress cracking.

- Strong Mineral Acids (HCl, H₂SO₄): These hydrolyze amide bonds, leading to total structural failure.

Thermal Performance & Heat Resistance

Operating Temperature vs Heat Deflection Temperature (HDT)

Use HDT at 1.8 MPa as the baseline metric for load-bearing parts because it standardizes how PA66 behaves under defined bending stress. This makes it useful for comparing grades and predicting stiffness loss under moderate load.

However, HDT does not capture real service complexity: time-at-temperature, creep under sustained stress, or fiber orientation. Treat HDT as a screening number. Validate final designs with CST, creep curves, and long-term aging at the actual service stress state.

Continuous Service Temperature (CST) — The Real Thermal Limit

Treat CST as the design limit, not the melt point. In practice, engineers apply conservative long-term thermal exposure limits because oxidation and creep accumulate over thousands of hours.

Unstabilized PA66 typically stays reliable around 80°C–90°C, while heat-stabilized or reinforced grades push sustained service closer to 100°C–120°C. Exceeding these ranges may retain short-term strength but risks premature failure through embrittlement, loss of modulus, or stress cracking. Always demand aging data that includes temperature, humidity, and load.

Performance Near Melting Point

PA66 melts near 265°C, but structural performance collapses well before that threshold. As temperature climbs, crystallites lose stiffness, hydrogen bonding weakens, and creep accelerates sharply.

Beyond the Glass Transition Temperature (Tg)—roughly 50°C to 70°C—PA66 begins to lose its “glassy” rigidity. Near the melt point, parts stop behaving like engineered components and start behaving like deformable solids—warping, relaxing, and losing fastener retention. Avoid designs operating near this range unless they see only brief, zero-load excursions.

Moisture Absorption & Dimensional Stability

How Water Absorption Changes Strength and Size

Treat water uptake as a mechanical property modifier, not an environmental side note. PA66 absorbs moisture because its amide groups attract water molecules, which act as a plasticizer within the polymer matrix. As absorption increases, chain mobility rises—improving impact toughness and resistance to brittle snap-fit failure.

However, moisture simultaneously reduces tensile strength and flexural modulus by weakening interchain hydrogen bonding. Expect dimensions to shift as the material swells; PA66 typically expands by 0.2% to 0.3% per 1% of moisture absorbed. Designers must specify the required moisture state (DAM vs. Conditioned) on technical drawings and avoid high-precision assemblies that cannot tolerate moisture-driven growth.

Nylon 6 6 vs Nylon 6 vs Nylon 11 (Moisture Comparison)

| Material | Typical Moisture Saturation | What It Means in Practice |

| PA6 | ~8.5% | Highest swelling and steepest modulus drop; makes tight tolerances difficult to maintain. |

| PA66 | ~2.5–3.0% | Moderate uptake; offers superior stiffness retention and dimensional control over PA6. |

| PA11 | ~1.9–2.1% | Exceptional dimensional stability; preferred for precision parts in submerged environments. |

Nylon 6 6 Grades & Reinforced Variants

Glass-Filled Nylon 6 6 (GF30, GF40)

Specify glass-filled PA66 when unfilled nylon cannot maintain stiffness under load or temperature. Adding 30% glass fiber (GF30) typically multiplies flexural modulus from ~3 GPa to ~9–12 GPa, which sharply reduces deflection and creep in structural parts.

That reinforcement also drives a major HDT jump: unfilled PA66 often sits near 70–90°C (1.8 MPa), while GF30 grades commonly exceed 240–260°C.

Move to GF40 when you require maximum rigidity and fastener retention, but expect increased brittleness and aggressive wear on mating surfaces. Treat fiber orientation as performance-critical; gate location and flow paths dictate anisotropy, warpage risk, and fatigue strength.

Heat-Stabilized & Impact-Modified Grades

- Heat Stabilized (HS): Specify HS PA66 for under-hood brackets and connectors exposed to continuous 100–120°C service to prevent oxidation and embrittlement.

- Impact Modified: Select these grades for clips and housings facing cold-weather impacts or vibration-driven cracking.

- HS + GF Variants: Required for structural EV motor-adjacent parts where stiffness must survive long-term thermal aging.

- Validation: Require aging data (hours-at-temp) and post-aging tensile/elongation values before finalizing your material selection.

Manufacturing & Processing Considerations

Injection Molding Constraints (Shrinkage, Warpage, Drying)

Ensure PA66 enters the barrel dry. Verify resin moisture stays <0.2% before molding; higher levels trigger hydrolysis during melt processing, which cuts molecular weight and destroys part toughness.

Expect shrinkage in the 1.0%–2.5% range depending on glass content and geometry. Design tooling with grade-specific data, not generic nylon values.

Control warpage by balancing flow paths and using uniform wall thickness to manage fiber orientation. Verify melt and mold temperatures, as PA66 crystallinity and thus stiffness shifts with processing.

Common Failure Modes Engineers Encounter in Practice

Treat surface defects as process signals. Splay usually indicates moisture confirm drying and hopper sealing. If parts become brittle, investigate over-drying or excessive residence time, which oxidizes the polymer and lowers elongation.

Watch for knit lines in complex molds; PA66 forms weld-line weaknesses when flow fronts meet cold. Raise melt temperatures and improve venting to keep fronts hot. Always cut tensile bars from weld-line regions during validation—these zones fail first in real-world assemblies.

Nylon 6 6 in3 D Printing (SLS & Additive Manufacturing)

PA66 performs well in Selective Laser Sintering (SLS) when the powder system controls crystallization. Printed PA66 delivers high heat resistance, but anisotropy remains dependent on build orientation.

Compared to injection molding, SLS PA66 offers more uniform properties across complex geometries by avoiding fiber alignment effects. However, it rarely matches the stiffness of GF-molded grades.

Use printed PA66 for functional prototypes or low-volume parts, and validate dimensional drift under humidity before end-use deployment.

Machining and Post-Processing Behavior

Manage heat aggressively during CNC machining. Use sharp tools and controlled feeds to prevent local melting. Verify chip evacuation; re-cutting hot chips distorts tolerances. Support thin walls to prevent vibration and avoid heavy finishing passes. If precision is critical, machine after conditioning because PA66 dimensions will shift significantly once it leaves the machine and absorbs ambient moisture.

Nylon 6 6 vs Other Engineering Plastics

Nylon 6 6 vs Nylon 6

Pick Nylon 6 6 when your part must retain stiffness and strength under heat and sustained load. PA66’s symmetrical chain structure builds a tighter crystalline matrix, improving creep resistance and thermal performance.

Pick PA6 when impact resistance and process latitude matter more than stiffness retention especially in thicker parts or applications that tolerate dimensional drift. PA6 absorbs more moisture, so it toughens significantly but loses modulus more dramatically.

Nylon 6 6 vs Nylon 11

Pick Nylon 11 when moisture stability and dimensional control are the design priorities. PA11 absorbs far less water than PA66, maintaining predictable dimensions in humid or wet environments ideal for tubing and fluid handling.

Pick Nylon 6 6 when load-bearing stiffness, wear resistance, and heat capability set the requirement.

If the part sees high heat and load, PA66 wins; if it sees moisture and aggressive chemicals, PA11 is the superior choice.

Nylon 6 6 vs Acetal (POM) for Precision Components

Pick POM (Acetal) when low friction, dimensional stability, and consistent dry running behavior matter more than heat-rated stiffness. POM excels in sliding mechanisms and precision gears where low moisture absorption keeps tolerances stable.

Pick Nylon 6 6 when the application demands higher temperature capability and fatigue endurance under cyclic load. While POM outperforms in tribology and tolerance control, PA66 handles higher stress and heat more confidently.

Nylon 6 6 vs ABS (When Strength Actually Matters)

Pick ABS when you require low cost, easy molding, and high-quality surface finish in non-structural housings. ABS offers good toughness indoors, but it softens early and cannot hold stiffness under load.

Pick Nylon 6 6 when mechanical performance drives the decision: load-bearing stiffness, fatigue endurance, and thermal stability in industrial service.

ABS wins for aesthetics and economy; PA66 wins when failure under stress carries high stakes.

Cost, Availability, and Supply Chain Reality

Price Drivers and Market Volatility

PA66 pricing tracks two levers: feedstock volatility and qualification cost. Hexamethylenediamine and adipic acid capacity constraints ripple through lead times for reinforced and heat-stabilized grades.

The Asia-Pacific region, specifically India, shows the highest CAGR in demand through 2026, driving global supply tension.

Procurement teams now pay a premium for certified circularity mechanically recycled content or chemically recycled feed stocks.

Designers must lock grade and stabilization packages early to prevent costly re-validation when suppliers rebalance formulations to meet sustainability targets.

Sustainability, Recycling and Bio-Based Alternatives

Treat sustainability as a specification constraint, not a marketing add-on. In practice, OEMs demand traceable supply chains for EV platforms.

Mechanical recycling works for clean waste, but fiber-filled PA66 often requires chemical recycling (depolymerization) back into virgin monomers for near-peak performance.

Suppliers like Toray have publicized subcritical-water depolymerization for high-yield recovery with lower CO₂ footprints. Specify recycled grades only after confirming property retention.

Key options include Ascend’s ReDefyne portfolio and Celanese’s ECO-R / ECO-B polyamides.

Key Manufacturers and Trade Names

- Zytel® (Celanese/DuPont): The industry-standard PA66 family for injection molding.

- Ultramid® (BASF): High-performance structural grades (GF30, GF40).

- Vydyne® (Ascend): Resins and compounds focusing on neat and impact-modified grades.

- Akulon® (Envalior): Broad engineering polyamide brand with strong PA66 offerings.

Final Recommendation — Should You Choose Nylon 6 6?

Decision Table by Application

| Application | Specify PA66 When… | Choose Another Material When… |

| High-speed gears | You need fatigue endurance and abrasion resistance under continuous load. | You require ultra-low friction and sub-micron tolerance stability. → POM |

| Structural brackets | Loads are high and parts must resist creep and heat aging (GF30/GF40). | Cost dominates or loads are low. → PP / PA6 |

| EV housings | Continuous heat exposure demands thermal stability and structural rigidity. | You need maximum dielectric stability under high humidity. → PBT / PPS |

| Electrical connectors | Mechanical retention forces require high stiffness and strength. | Moisture cycling drives insulation failure or dielectric risk. → PBT |

| Snap-fits and clips | You need toughness combined with high-temperature capability. | Consistent snap behavior is required regardless of humidity. → POM / ABS |

| Precision parts | You can validate tolerances after conditioning and control humidity exposure. | Moisture-driven swelling is unacceptable for the assembly. → PA11 / POM |

Engineer’s Selection Checklist

Confirm PA66 fits your application by verifying these criteria:

- Load-Bearing: The component must carry sustained load without excessive creep.

- Heat Exposure: Service temperatures exceed the safe range of ABS, PP, or commodity nylons.

- Fatigue Cycles: The design requires endurance against repetitive stress (gears, mounts, brackets).

- Reinforcement: You can specify GF30/GF40 to meet stiffness and fastener retention targets.

- Moisture Accounting: You have validated dimensions and strength at the Conditioned state.

- Chemical Fit: Exposure involves hydrocarbons or salts—not strong mineral acids or ZnCl₂.

- Processing: You can ensure resin drying to <0.2% moisture and maintain stable molding.

FAQs

Is Nylon 6 6 UV stable for outdoor use?

Standard PA66 is susceptible to UV degradation, which leads to surface chalking, brittleness, and loss of tensile strength over time.

For outdoor service, you must specify carbon-black pigmented or UV-stabilized grades (often labeled ‘black’ or ‘UV’ in data sheets).

These additives absorb or screen UV radiation, significantly extending the part’s mechanical life in direct sunlight.

What is the difference between Nylon 6 6 and Nylon 6?

The primary difference lies in thermal and mechanical limits.

Nylon 6 6 has a higher melting point (~265°C vs. ~220°C), higher stiffness, and better creep resistance.

Nylon 6 offers better impact resistance, a better surface finish, and easier processing at a lower cost, but it absorbs more moisture, leading to higher dimensional instability and a greater loss of stiffness in humid environments.

Should Nylon 6 6 parts be annealed?

Annealing—heating parts in a controlled environment is used to relieve internal molded-in stresses and stabilize dimensions. While not required for all parts, specify annealing for thick-walled components or high-precision gears to prevent post-molding warpage.

In practice, many engineers prefer moisture conditioning over annealing to reach equilibrium dimensions and toughness before assembly.

What is the best way to bond or join Nylon 6 6 parts?

Because of its crystalline nature and chemical resistance, PA66 is difficult to bond with standard solvents. For high-strength structural joints, use ultrasonic welding, vibration welding, or laser welding.

If adhesives are required, specify two-part structural epoxies or cyanoacrylates after surface treatment (such as plasma or corona discharge) to increase surface energy and bond strength.