Polycarbonate ABS Material (PC-ABS): Properties, Processing & Selection Guide

This technical guide provides essential mechanical specifications, thermal thresholds, and processing parameters for Polycarbonate ABS Material.

You will learn to optimize material properties for high-impact applications, compare cost-performance trade-offs, and implement critical injection molding or 3D printing protocols to prevent part failure.

What Is Polycarbonate ABS Material?

PC-ABS is a high-performance thermoplastic alloy created by mechanically blending Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS). This blend eliminates the individual weaknesses of both polymers, resulting in a material that is easier to process than pure PC and significantly tougher than standard ABS.

Why Polycarbonate and ABS Are Blended

The synergy between these two polymers creates a balance of physical and economic benefits:

- Enhanced Impact Strength: PC adds a high notched Izod impact resistance, ensuring parts do not shatter under stress.

- Thermal Stability: The blend maintains structural integrity at temperatures where pure ABS would deform.

- Superior Processability: ABS reduces the melt viscosity of PC, allowing for lower injection pressures and thinner wall designs.

- Cost Efficiency: Replacing a percentage of PC with ABS significantly lowers the raw material cost without a linear loss in performance.

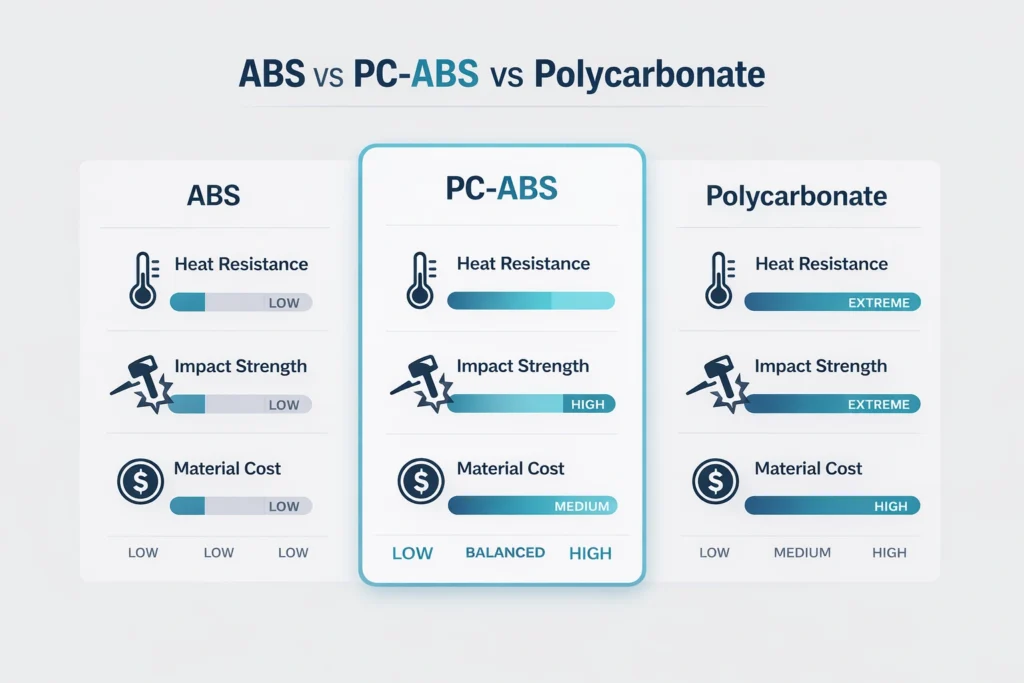

How PC-ABS Differs from Pure ABS and Pure Polycarbonate

The following table highlights why PC-ABS is the preferred middle-ground for engineering:

| Property | ABS (Standard) | PC-ABS (Blend) | PC (Polycarbonate) |

| Heat Deflection (HDT) | ~85°C | 95°C – 125°C | ~135°C |

| Izod Impact (Notched) | 10–20 kJ/m² | 30–55 kJ/m² | 60–80 kJ/m² |

| Processing Ease | Excellent | Good/Moderate | Difficult (High Viscosity) |

| Surface Finish | High Gloss | High/Matte | Moderate |

Mechanical and Thermal Properties of PC-ABS

PC-ABS is engineered for environments where standard plastics fail. Its performance is defined by high energy absorption and a stable molecular structure under thermal stress.

Impact Strength, Toughness, and Structural Performance

PC-ABS excels in high-strain rate environments. It typically delivers a Notched Izod Impact strength of 40–60 kJ/m².

- Low-Temperature Ductility: Unlike many plastics that become brittle, PC-ABS retains significant impact resistance at -30°C, preventing catastrophic shattering in cold-weather applications.

- Flexural Modulus: It offers a high stiffness-to-weight ratio, generally ranging between 2,300 and 2,700 MPa.

Heat Deflection Temperature and Dimensional Stability

The material bridges the gap between consumer plastics and high-heat polymers.

- Thermal Limits: Standard grades provide an HDT of 95°C to 125°C at 0.45 MPa.

- Precision: It features a low Coefficient of Thermal Expansion (CTE), ensuring parts maintain tight tolerances despite temperature fluctuations. This makes it ideal for mating parts in complex assemblies.

Chemical Resistance and Environmental Degradation

Warning: PC-ABS is highly susceptible to Environmental Stress Cracking (ESC) when exposed to specific solvents.

| Chemical Group | Rating | Common Examples to Avoid |

| Alcohols | Pass | Ethanol, Isopropyl Alcohol (Short exposure) |

| Ketones | Fail | Acetone, MEK (Causes immediate softening) |

| Esters/Ethers | Fail | Ethyl Acetate, THF |

| Oils/Greases | Limited | Motor oils (May cause long-term cracking) |

Electrical and Flame-Retardant Grades (UL Ratings)

PC-ABS is the industry standard for non-conductive enclosures.

- Flame Retardancy: Specialized grades achieve UL 94 V-0 ratings at thicknesses as low as 1.5mm, meaning burning stops within 10 seconds.

- Compliance: Many blends meet UL 94 5VA standards for high-voltage industrial housings, providing superior protection against electrical ignition.

PC-ABS vs ABS vs Polycarbonate: Engineering Comparison

Choosing between these materials requires balancing mechanical limits against total cost of ownership. PC-ABS is the strategic choice when ABS is too weak and pure Polycarbonate is over-engineered or too costly to process.

Strength, Rigidity, and Creep Resistance

While ABS serves well for static covers, PC-ABS is required for load-bearing components.

- Creep Resistance: PC-ABS significantly outperforms pure ABS in resisting permanent deformation under sustained mechanical stress.

- Structural Integrity: It maintains higher rigidity at elevated temperatures, ensuring snap-fits and bolted assemblies do not loosen or “relax” over time, a common failure point in standard ABS.

Surface Finish and Aesthetic Performance

PC-ABS is the premier choice for consumer-facing hardware due to its superior surface energy and resin flow.

- Secondary Finishing: It is specifically engineered for electroplating and painting. The ABS component allows for excellent metal-to-plastic adhesion, making it the standard for “chrome” automotive trim.

- Aesthetic Versatility: It achieves high-gloss finishes or deep textures without the “silvering” or flow lines often seen in pure PC.

Cost and Performance Trade-Offs

Engineers utilize PC-ABS to optimize the budget-to-performance ratio:

- Efficiency: PC-ABS offers approximately 80% of pure Polycarbonate’s physical performance (impact and heat) but at only 60% of the processing difficulty.

- Value Proposition: By lowering the required melt temperature compared to pure PC, it reduces energy consumption and cycle times during manufacturing, providing a lower “per-part” cost for high-performance requirements.

Manufacturing and Processing PC-ABS

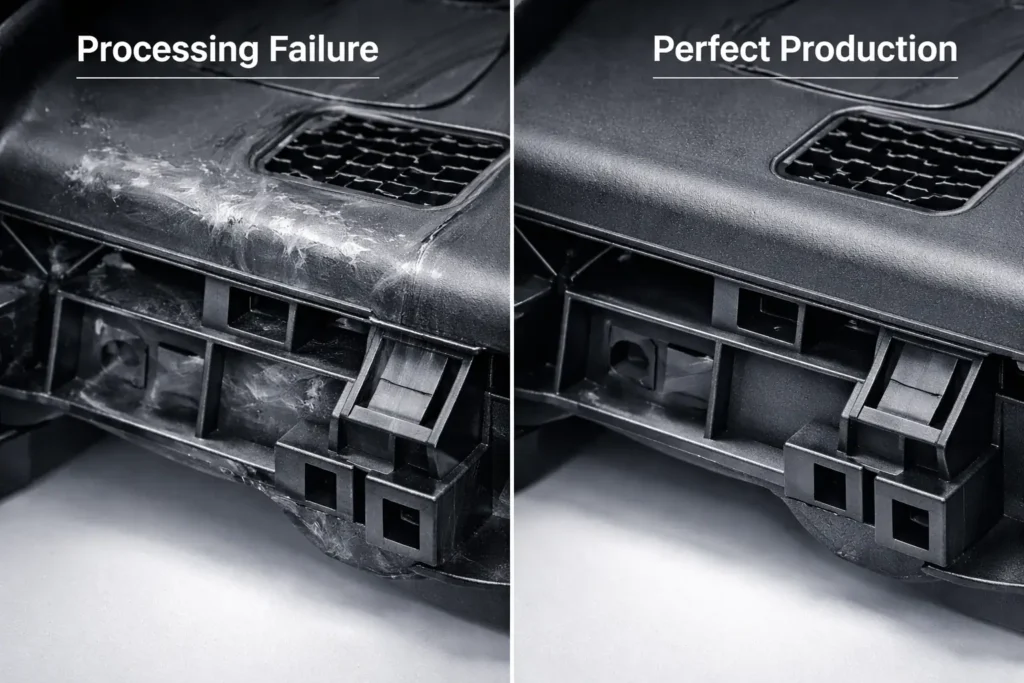

Successful production with PC-ABS requires strict thermal management. Deviating from validated set points leads to internal stresses and compromised mechanical properties.

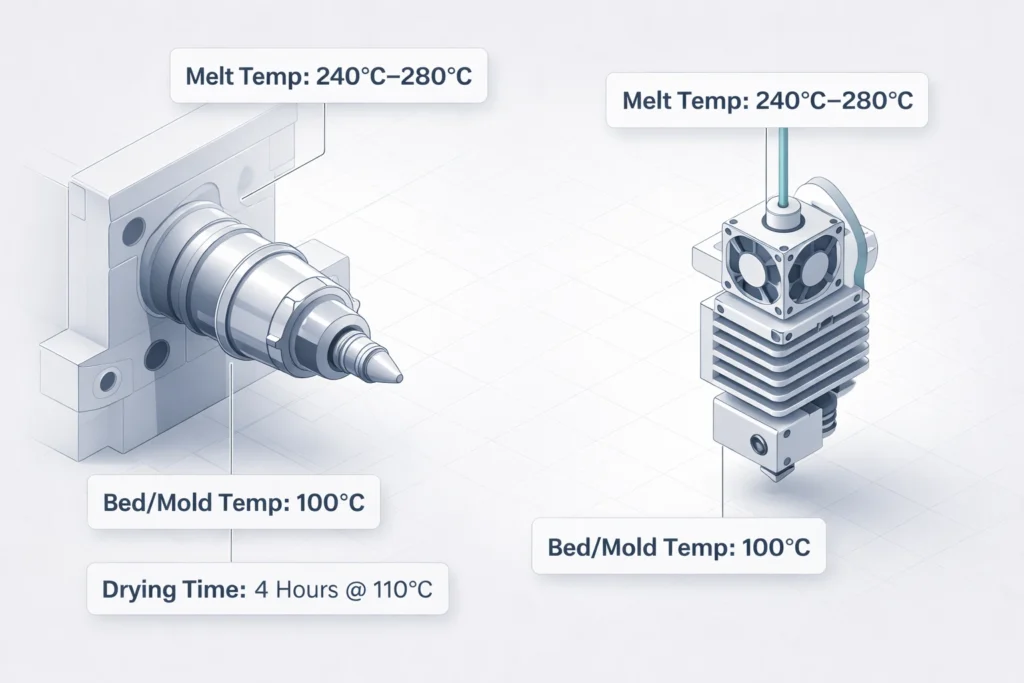

Injection Molding: Melt Temperature, Mold Temperature, and Shrinkage

To achieve a homogenous melt and optimal surface finish, use the following industry-standard parameters:

- Melt Temperature: 240°C – 280°C. Avoid exceeding 300°C to prevent polymer degradation.

- Mold Temperature: 70°C – 100°C. Higher mold temps improve weld line strength and surface gloss.

- Shrinkage Rate: Typically 0.5% – 0.7%. This low, predictable rate allows for high-precision dimensional tolerances in complex geometries.

Additive Manufacturing: FDM 3D Printing with PC-ABS

PC-ABS is the “gold standard” for functional prototypes. For successful prints, adhere to these technical requirements:

- Nozzle Temperature: 260°C – 280°C.

- Bed Temperature: 100°C+ is mandatory to ensure first-layer adhesion.

- Environmental Control: An actively heated enclosure is required. Without a controlled environment, the material’s high shrink rate causes severe interlayer delamination and warping.

Moisture Sensitivity and Drying Requirements

Critical Failure Risk: PC-ABS is highly hygroscopic. Processing “wet” resin causes hydrolysis, which permanently breaks the polymer chains and reduces impact strength by up to 50%.

- Drying Protocol: Dry resin at 100°C – 110°C for 3 – 4 hours in a desiccant dryer.

- Target Moisture: Must be below 0.02% before processing. Never rely on the “visual appearance” of the pellets.

Common Molding Defects and Process Controls

Use this diagnostic guide to troubleshoot production issues:

- Splay (Silver Streaks) →Inadequate drying; check moisture content and dryer dew point.

- Warping →Non-uniform cooling; increase mold temperature or extend cooling cycle.

- Delamination →Melt temperature too low or contamination; increase barrel heat.

- Burn Marks →Excessive injection speed or poor venting; reduce injection velocity.

Machining and Secondary Operations

Post-processing PC-ABS requires precision to avoid thermal damage. Because this blend combines a high-softening-point plastic (PC) with a lower-melting one (ABS), friction management is critical.

CNC Machining Considerations

PC-ABS machines well but is prone to localized melting if heat builds up at the tool tip.

- Tooling: Use razor-sharp, un-coated carbide bits designed for plastics to ensure clean chips.

- Heat Control: Utilize flood coolant or compressed air. High spindle speeds without adequate cooling will cause the resin to gum, resulting in poor dimensional accuracy.

- Feed Rates: Maintain high feed rates to prevent the tool from “rubbing” the material.

Laser Cutting, Bonding, and Surface Finishing Risks

Secondary assembly requires chemical caution to prevent structural failure.

- Adhesives: Use two-part epoxies or high-viscosity cyanoacrylates for structural bonds.

- Solvent Welding Warning: Avoid traditional solvent welding (common with pure ABS). Solvents like MEK cause immediate stress cracking and embrittlement in the PC component.

- Laser Cutting: Use high-pressure air assist to minimize the charred heat-affected zone (HAZ) and prevent toxic fume accumulation.

Industrial Applications of PC-ABS Material

PC-ABS is the high-performance workhorse for structural housings and aesthetic components. Its selection is driven by the need for crashworthiness in automotive and flame retardancy in electronics.

Automotive, Electronics, and Safety Parts

Manufacturers standardize on PC-ABS when standard ABS lacks the thermal ceiling or impact strength required for safety-critical environments.

- Automotive Interiors: Used for dashboards, instrument panels, and overhead consoles. It withstands extreme cabin heat without warping or losing its “soft-touch” finish.

- Consumer Electronics: The industry standard for laptop shells, smartphone frames, and portable battery housings. It provides thin-wall rigidity and protects internal circuitry from drop impacts.

- Medical Technology: Found in medical monitors and diagnostic equipment housings. It offers the durability needed for hospital environments while maintaining a premium aesthetic.

- Safety Equipment: Utilized in protective helmets and industrial tool enclosures where high energy absorption is mandatory to protect the end-user.

Sustainability and Life Cycle of PC-ABS

The environmental impact of PC-ABS is increasingly mitigated through closed-loop industrial recycling and the adoption of Post-Consumer Resin (PCR) blends.

Recyclability and Environmental Impact (Post-Consumer Resin)

While PC-ABS falls under Resin Identification Code 7 (Other), making it difficult for curbside pickup, it is highly valued in industrial recycling streams.

- Regrind Compatibility: Industrial scrap can be reground and blended with virgin resin (typically up to 20%) without significant loss in mechanical properties.

- PCR Blends: Top-tier suppliers now offer PCR PC-ABS, which incorporates up to 65% recycled content, drastically reducing the carbon footprint of electronic and automotive housings while maintaining UL 94 compliance and structural integrity.

When to Choose Polycarbonate ABS Material

Selecting PC-ABS is a strategic decision based on the balance of thermal limits and mechanical impact requirements. Use this matrix for a rapid “Go/No-Go” assessment.

Decision Matrix (When to use vs. when to skip)

Use PC-ABS if:

- You require heat resistance above 95°C but cannot justify the cost of pure Polycarbonate.

- The application demands low-temperature toughness (parts must not shatter at -20°C).

- High dimensional stability is required for tight-tolerance snap-fits or electronic enclosures.

Avoid PC-ABS if:

- The part will face prolonged UV exposure (it will yellow and embrittle without stabilizers).

- The environment involves harsh solvents, ketones, or esters (risk of immediate stress cracking).

- Budget is the only driver and mechanical performance is secondary (Standard ABS is 20-30% cheaper).

Final Engineering Checklist for Selecting PC-ABS

Before finalizing your material specification, verify your application against these five critical technical requirements to ensure long-term part reliability:

- Drying Verification: Do you have a desiccant dryer capable of hitting 100°C–110°C? Processing with >0.02% moisture will lead to hidden hydrolysis and part failure.

- Thermal Ceiling: Does your continuous use temperature remain 20°C below the material’s Heat Deflection Temperature (HDT)?

- Chemical Environment: Will the part contact ketones, esters, or industrial solvents? If yes, expect Environmental Stress Cracking (ESC).

- Regulatory Compliance: Does the application require UL 94 V-0 flame retardancy or specific automotive OEM certifications?

- Economic Justification: Can the design utilize thinner walls enabled by PC-ABS’s strength to offset its higher cost compared to standard ABS?

FAQs

Is PC-ABS stronger than pure Polycarbonate?

No. Pure Polycarbonate (PC) has higher ultimate tensile strength and impact resistance. However, PC-ABS is more practical for complex designs because it flows better during molding, leading to fewer internal stresses and more consistent part strength in thin-walled applications.

Does PC-ABS need to be dried before 3D printing or molding?

Yes, absolutely. PC-ABS is hygroscopic. You must dry it at 100°C–110°C for 3–4 hours. Failure to do so causes hydrolysis, which chemically destroys the polymer chains, resulting in brittle parts and visible surface “splay.”

Can PC-ABS be used outdoors?

Only with UV stabilizers. Standard PC-ABS degrades under ultraviolet light, leading to yellowing and significant loss of impact strength. For outdoor use, specify UV-stabilized grades or apply a UV-resistant protective coating/paint.

What is the best adhesive for bonding PC-ABS?

Use two-part epoxies or high-performance cyanoacrylates. Avoid solvent-based cements (like those used for PVC or pure ABS), as they can cause Environmental Stress Cracking (ESC) in the Polycarbonate component of the blend.

Why is my PC-ABS part warping?

Warping is usually caused by uneven cooling or low mold/bed temperatures. Ensure your mold is set between 70°C–100°C, or if 3D printing, use a heated enclosure and a bed temperature of at least 100°C to manage the material’s 0.5–0.7% shrinkage rate.