Quick Turn Injection Molding: When Speed, Cost, and Part Quality Matter

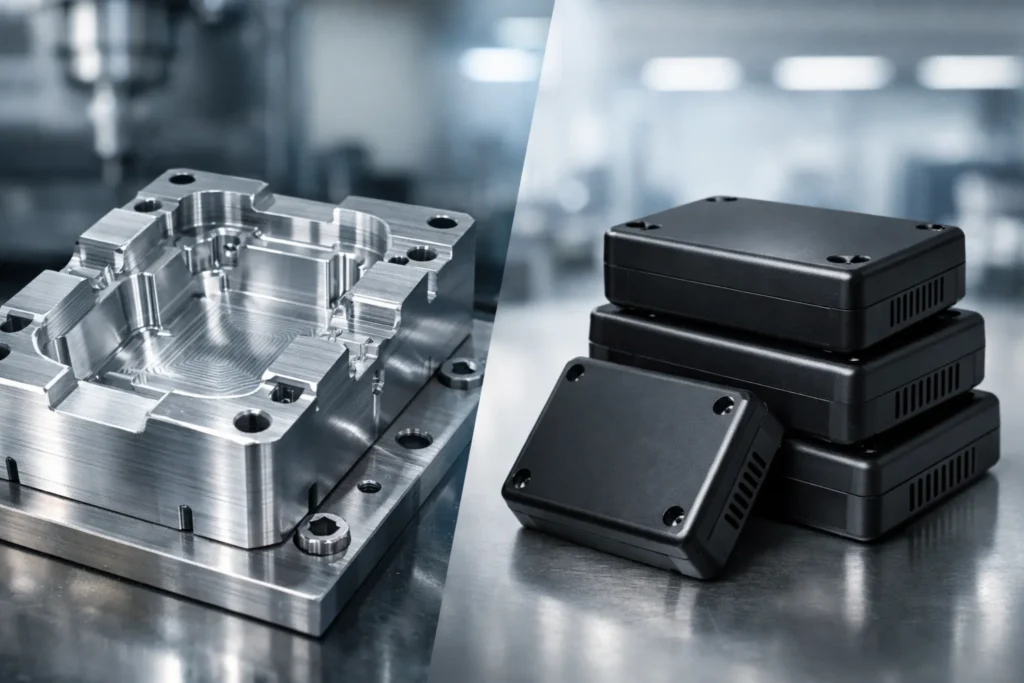

Quick turn injection molding accelerates product development by utilizing automated DFM analysis and aluminum tooling to deliver production-grade plastic parts in days rather than months.

This process bypasses the lengthy fabrication cycles of traditional steel molds, allowing engineers to validate designs with final-market materials under aggressive deadlines.

Quick Turn Essentials

- Lead Time: 5 – 15 business days (Standard: 10+ weeks).

- Production Volume: 10 – 10,000+ units.

- Primary Tooling: High-strength Aluminum (QC-10) or pre-hardened steel.

What “Quick Turn” Really Means in Injection Molding

Quick Turn” is not just a speed upgrade; it is a structural shift from manual craftsmanship to digital-first manufacturing.

By replacing hardened steel with high-strength aluminum and integrating automated CNC toolpaths, this process removes the months-long bottlenecks traditional molding requires. This allows for rapid bridge production and hardware iteration at the speed of software development.

Typical Lead Times vs Conventional Injection Molding

The following table highlights why Quick Turn is the industry standard for time-sensitive projects:

| Feature | Quick Turn Molding | Conventional Molding |

| Tooling Lead Time | 1 – 2 Weeks | 10 – 14 Weeks |

| Initial Tooling Cost | $2,000 – $5,000 | $15,000 – $50,000+ |

| Iteration Speed | Fast (7-10 Days) | Slow (4-6 Weeks) |

| Typical Tool Life | 1,000 – 10,000+ Cycles | 1,000,000+ Cycles |

What Changes in Tooling and Process to Enable Speed

Quick Turn utilizes CNC-driven mold making, where automated software converts 3D CAD files directly into machining toolpaths, eliminating manual drafting.

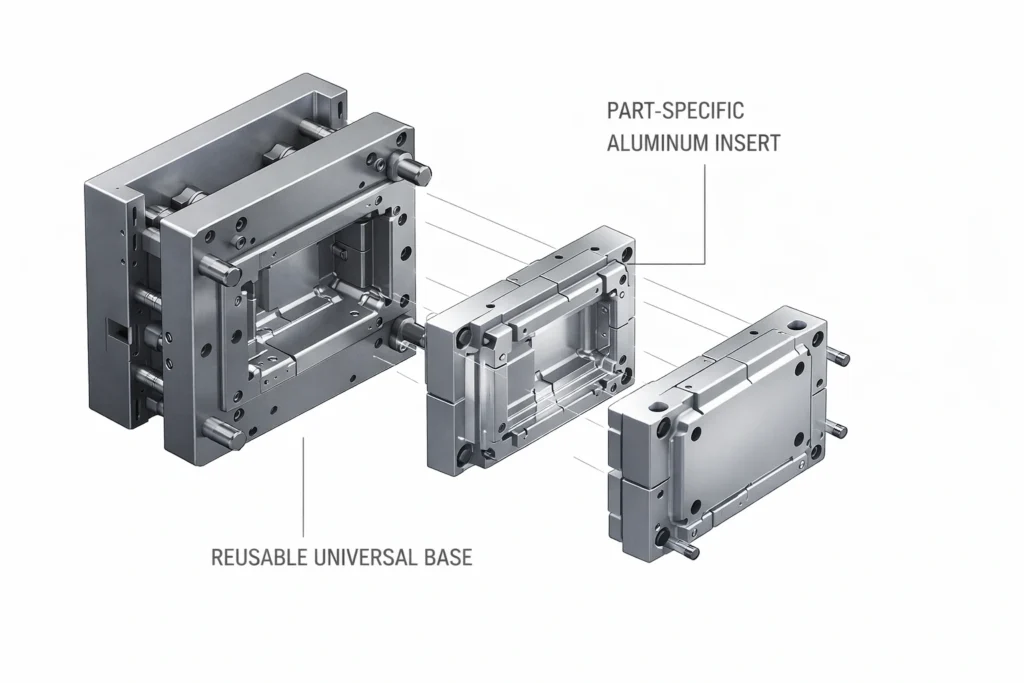

To further compress timelines, manufacturers use Master Unit Die (MUD) inserts. Instead of building a complete, standalone mold base, engineers only machine the “cavity and core” inserts that fit into a pre-existing universal frame.

Crucially, aluminum dissipates heat 5x faster than steel, which significantly reduces cooling times. This allows for shorter cycle times per part, enabling machines to produce hundreds of units in hours rather than days once the tool is mounted.

When Quick Turn Injection Molding Is the Right Choice

Quick turn injection molding is the strategic solution for projects where speed-to-market outweighs long-term tool durability. It solves the critical “valley of death” in hardware development: the period when 3D prints are too weak for testing, but high-volume steel tooling is months away from completion.

Prototype, Bridge, and Low-Volume Production Scenarios

- Bridge Production: Use this to fulfill initial orders and generate revenue while your multi-cavity steel production tool is being fabricated overseas.

- Functional Prototyping: Unlike 3D printing, you get parts in production-grade resins (e.g., glass-filled Nylon or PEI) to verify mechanical properties, chemical resistance, and UL ratings.

- Market Validation: Produce 500 to 2,000 units for pilot launches or Kickstarter fulfillment without the $20,000 upfront risk of traditional molds.

Part Geometry and Tolerance Limits You Must Accept

To achieve these speeds, you must design within specific constraints. Aluminum is softer than steel and machined via high-speed CNC, which imposes these “hard” limits:

- Tolerances: Standard achievable tolerance is +/- 0.005” (0.127mm). While tighter tolerances are possible, they exponentially increase cost and lead time.

- Draft Angles: Zero-draft walls are deal-breakers. Aluminum molds require at least 0.5° to 2° of draft to prevent part sticking and tool damage.

- Deep Ribs: Deep, thin ribs are difficult to CNC-machine into aluminum; they often require EDM (Electrical Discharge Machining), which adds days to your “Quick Turn” schedule.

Design for Speed: DFM Best Practices for Quick Turn Molding

Designing for quick turn injection molding requires a “machining-first” mindset. Because molds are cut using high-speed CNC mills, your part geometry must allow for rapid tool access and efficient plastic flow. Optimizing these variables during the CAD phase is the difference between a 5-day turnaround and a design-rejection notice.

Critical Adjustments: Wall Thickness, Draft Angles, and Undercuts

To maximize yield and minimize cycle time, adhere to these technical thresholds:

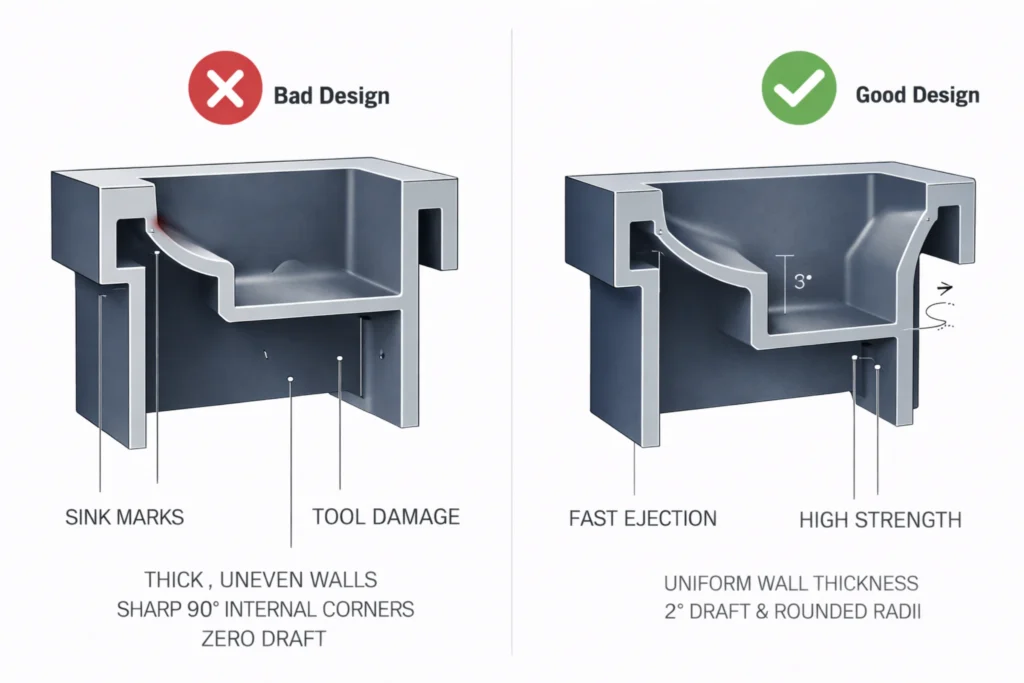

- Uniform Wall Thickness: Maintain a range between 0.040″ (1.0mm) and 0.120″ (3.0mm). Non-uniform walls cause sink marks and warpage because thin sections cool faster than thick ones. If you must vary thickness, use a gradual transition of no more than 25% of the wall’s nominal thickness.

- Draft Angles: Aluminum tools lack the lubricity of hardened steel. You must implement a minimum draft of 0.5° to 1.0° on all vertical faces. For parts requiring VDI or MT textures, increase this to 3° to 5° to prevent drag marks during ejection.

- Radii and Fillets: Replace sharp 90-degree internal corners with a minimum radius of 0.020”. Sharp corners act as stress concentrators for the plastic and are impossible to machine into a mold with round end mills without specialized, slow EDM processes.

- Bosses and Ribs: Design ribs at 40-60% of the thickness of the mating wall. This provides structural rigidity without creating “hot spots” that lead to surface depressions.

Tooling Strategies Used in Quick Turn Injection Molding

Strategic tooling selection is the primary lever for compressing lead times. By selecting materials and architectures optimized for CNC accessibility rather than multi-year durability, manufacturers can slash the “design-to-part” window by over 80%.

Aluminum vs Steel Molds for Fast Turnaround

The choice between QC-10 Aluminum and P20 Pre-hardened Steel dictates both speed and part quality.

- Aluminum (The Speed Leader): Aluminum is the gold standard for quick-turn projects because it is 3x faster to machine than steel. Its superior thermal conductivity allows parts to cool rapidly in the mold, reducing cycle times and increasing throughput. Use this for volumes up to 10,000 units.

- P20 Steel (The Hybrid): While slower to machine than aluminum, P20 steel does not require the lengthy heat-treatment cycles of “T-series” tool steels. It offers better resistance to abrasive resins (like glass-filled Nylon) while still qualifying as a “rapid” tooling option for volumes up to 50,000 units.

Modular and Family Tooling Approaches

To eliminate the cost and time of building a full mold base, two specialized strategies are employed:

- MUD (Master Unit Die) Inserts: Instead of a bespoke mold, the manufacturer machines only the core and cavity blocks. These “inserts” slide into a standard, pre-existing frame. This reduces the amount of metal to be cut and lowers the Non-Recurring Engineering (NRE) costs by up to 50%.

- Family Tooling: If your product consists of several small, related parts (e.g., a top and bottom housing) made of the same material, they can be cut into the same mold plate. This “family” approach ensures all components are produced in the same shot, guaranteeing color and material consistency while cutting tooling costs in half.

Material Selection for Quick Turn Injection Molding

Selecting the correct resin is critical because material behavior directly impacts mold dimensions and cycle times. In quick turn molding, we prioritize materials with predictable shrinkage rates to ensure first-article success without time-consuming tool modifications.

Common Thermoplastics That Mold Reliably at Speed

While thousands of resins exist, the “Big 5” offer the most reliable performance for rapid tooling:

- ABS (Acrylonitrile Butadiene Styrene): The best all-rounder. Low shrinkage and excellent dimensional stability make it the primary choice for housings.

- PC (Polycarbonate): High impact resistance and clarity. Requires higher processing temperatures; can be prone to internal stress.

- Nylon (PA): Exceptional strength and wear resistance. Shrinkage varies significantly based on glass-filler content.

- PP (Polypropylene): Excellent chemical resistance and fatigue life (for living hinges). High shrinkage rate (0.015-0.025 in/in) requires precise tool design.

- TPE/TPU: Ideal for soft-touch overmolding and seals. Requires careful venting in aluminum tools to prevent burning.

Material Trade-offs: Strength, Finish, and Mold Life

The interaction between resin and aluminum tooling creates specific operational risks:

| Material | Key Property | Quick-Turn Risk |

| Nylon (PA) | High Strength | Hydroscopic: Absorbs moisture rapidly; improper drying causes splay and delays. |

| Polycarbonate | Impact Resistance | Flash Risk: High flow temperature can cause “flash” on aluminum parting lines. |

| Glass-Filled Resins | Rigidity | Abrasiveness: Glass fibers erode aluminum cavities faster than unfilled resins. |

| ABS | Aesthetics | Weld Lines: Fast cooling in aluminum can make weld lines more visible. |

Cost Breakdown: Quick Turn vs Standard Injection Molding

Quick turn injection molding shifts the financial burden from upfront capital (CAPEX) to operational cost per unit. While traditional molding amortizes expensive steel tools over millions of cycles, quick turn focuses on minimizing the Non-Recurring Engineering (NRE) costs to facilitate rapid market entry.

Tooling Cost vs Per-Part Cost Reality

The financial logic of quick turn molding is defined by the Total Cost of Ownership (TCO) at low volumes:

- Quick Turn: Low entry cost ($2,000+) but higher piece price due to single-cavity tools and manual processing.

- Standard: High entry cost ($15,000+) but significantly lower piece price via multi-cavity, fully automated steel tools.

When Fast Becomes More Expensive Long-Term

The break-even point typically occurs between 5,000 and 10,000 units. Beyond this threshold, the labor and cycle-time inefficiencies of aluminum tooling outweigh the initial savings.

The Rule of Thumb:

- < 5,000 units: Quick Turn is almost always more cost-effective.

- > 10,000 units: Transition to production steel tooling to capture lower per-part costs and long-term durability.

Quality, Risk, and Performance Considerations

While quick turn molding provides production-quality geometry, cosmetic expectations must be calibrated to the tooling material. Aluminum is softer and more porous than hardened steel, which impacts the final surface texture and tool longevity.

Surface Finish, Cosmetic Limits, and Consistency

Standard finishes like SPI-B1 (600 Grit) or SPI-C1 (60-90 Grit) are achieved easily on aluminum. However, “Class A” high-gloss diamond polishes (SPI-A2) are significantly harder to maintain. These finishes require extensive manual labor and can add 2–3 days to your lead time. If your part requires a mirror finish, expect higher scrap rates as aluminum shows microscopic scratches more readily than steel.

Tool Wear, Part Variation, and Scaling Risks

The primary technical risk is galling, where the soft aluminum surfaces of the mold halves rub together, causing metal transfer and part deformation. This is especially prevalent in tools with zero-draft features or those running glass-filled resins. Over time, this wear leads to part variation and increased flash, making aluminum unsuitable for scaling beyond the initial 10,000-unit threshold.

From Design to Dock: A Case Study in Rapid Bridge Production

This section demonstrates the real-world application of quick turn principles through a high-stakes engineering project. By prioritizing manufacturability over complexity, we bypassed traditional lead-time bottlenecks.

Lessons Learned: Solving Common Injection Challenges on a Tight Deadline

Situation:

A medical device startup required 500 functional enclosures in USP Class VI Polycarbonate for human clinical trials. The deadline was 12 business days. A traditional steel tool quote came in at 10 weeks, which would have compromised the trial launch and investor milestones.

Action:

We performed a Rapid DFM Analysis and identified two complex internal undercuts that required mechanical side-actions. To save time, we collaborated with the client to redesign the undercuts into “pass-through” features (shut-offs). This modification allowed the mold to be cut as a simple “straight-pull” aluminum tool, eliminating the need for complex moving parts.

Result:

- Delivery: Finished parts were on-dock in 9 business days.

- Cost: Tooling expenses were 60% lower ($4,200 vs. $11,500) compared to a steel production mold.

- Outcome: The client successfully launched the trial on schedule with parts that met all regulatory and mechanical requirements.

Quick Turn Injection Molding vs Alternative Fast Manufacturing Methods

Selecting the optimal rapid manufacturing process depends entirely on your volume threshold and material requirements. While 3D printing and CNC machining offer speed, they cannot replicate the isotropic strength and surface finish of a molded part.

Comparison with CNC Machining and Industrial 3D Printing

Choose 3D Printing (SLA/SLS/FDM) If:

- You need 1–10 units for basic form and fit testing.

- The design has impossible geometries (internal lattices) that cannot be machined.

- Speed is the only factor, and material properties (like UV resistance) are secondary.

Select CNC Machining If:

- You need 1–20 units in a specific production metal or plastic.

- The part has extremely tight tolerances (+/- 0.001”) that molding cannot hit.

- You want to avoid any upfront tooling investment (NRE).

Choose Quick Turn Injection Molding If:

- You need 100 to 10,000 units with high repeatability.

- The project requires final-market resin properties (e.g., UL 94-V0 flammability).

- You need to validate the manufacturing process itself before mass production.

How to Decide If Quick Turn Injection Molding Is Right for Your Project

Selecting the wrong manufacturing path results in thousands of dollars in wasted Non-Recurring Engineering (NRE) costs and months of lost time. Use this practitioner’s checklist to determine if quick turn injection molding aligns with your project’s technical and commercial requirements.

Decision Checklist Based on Volume, Timeline, and Budget

- Is your total volume between 100 and 10,000 units? If you need fewer than 100, 3D printing is likely more economical; if you need more than 10,000, hardened steel tooling offers a better long-term ROI.

- Does your project require specific production-grade thermoplastics? Quick turn is the only rapid method that allows for final-market testing with resins like Glass-filled Nylon, PEI, or medical-grade Polycarbonate.

- Can the part geometry be machined with 3-axis CNC? Quick turn molds are cut via high-speed mills. If your design avoids complex undercuts or can be modified with simple side-actions, it is an ideal candidate for rapid tooling.

- Is your target lead time under 3 weeks? Traditional tooling will not meet this window. Aluminum inserts are the only way to move from CAD to physical parts in 5–15 business days.

When to Transition from Quick Turn to Full Production Tooling

Transition to high-volume steel tooling when your monthly demand exceeds 2,500 units or when your part requires Class A mirror finishes that would prematurely wear an aluminum tool.

Final Call to Action: If you checked the boxes for volume, material, and geometry, Quick Turn Injection Molding is your optimal path to market.

FAQs

How fast can I get parts with quick turn injection molding?

Standard lead times range from 5 to 15 business days. Speed depends on part complexity and material availability. Simple “straight-pull” designs without side-actions are typically delivered within one week, while parts requiring custom textures or overmolding may take the full 15 days.

What is the typical cost of a quick turn injection mold?

Initial tooling costs generally fall between $2,000 and $5,000. This is significantly lower than traditional steel tooling ($15,000+) because it utilizes aluminum MUD inserts and automated CNC machining, which reduces labor and material expenses.

How many parts can an aluminum quick turn mold produce?

An aluminum mold typically supports 1,000 to 10,000 cycles. For non-abrasive resins like ABS or Polypropylene, the tool may last longer. However, if using glass-filled resins, tool wear (galling) will occur sooner, typically around the 5,000-unit mark.

Can I use production-grade resins in quick turn molding?

Yes. Unlike 3D printing, quick turn injection molding uses actual production thermoplastics including ABS, PC, Nylon (PA6, PA 66), PBT, and TPE. This allows for accurate testing of mechanical properties, chemical resistance, and thermal performance before mass production.

What is the difference between bridge tooling and quick turn molding?

Quick turn molding is the process, while bridge tooling is the application. Bridge tooling uses the quick turn process to produce parts for market launch while a high-volume, multi-cavity steel tool is being built, ensuring there is no gap in your supply chain.