Strongest Plastic for Injection Molding: Material Selection Guide for High-Stress Parts

Selecting the strongest plastic for injection molding requires balancing tensile strength, impact resistance, and thermal stability. This guide ranks industrial-grade resins and high-performance polymers, providing the technical data needed for precise resin selection in high-stress, load-bearing applications.

What “Strongest” Means in Injection Molding Applications

In engineering, “strongest” is never a single value; a material that resists snapping under tension may shatter instantly upon impact. True material strength is application-specific, requiring a balance between raw force resistance and environmental survival.

Plastics vs. Metals: Understanding Specific Strength

For many high-stress applications, plastics outperform metals due to Specific Strength (the strength-to-weight ratio). This allows engineers to achieve structural integrity while drastically reducing assembly weight.

- PEEK vs. Steel: PEEK provides a similar tensile strength to some aluminum alloys but at half the weight, making it the premier choice for aerospace weight reduction.

- Reinforced Nylon vs. Die-Cast Aluminum: Glass-filled Nylon 66 offers high rigidity and better vibration damping than aluminum, preventing fatigue-related failures in automotive engines.

- Weight Advantage: Switching from metal to high-strength polymers often reduces part weight by 40% to 70%, directly improving fuel efficiency and handling.

Tensile Strength vs Impact Resistance vs Load-Bearing Strength

- Tensile Strength: Measures the force required to pull a part until it reaches a permanent stretch or snap.

- Impact Resistance: Measures energy absorption, determining if a part will shatter or crack when struck by a sudden force.

- Load-Bearing (Compressive) Strength: Defines the material’s ability to support weight without crushing or deforming.

Short-Term Strength vs Long-Term Service Performance

A plastic’s initial strength rating can be misleading because polymers are subject to Creep. Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses.

A part may handle a heavy load for an hour but slowly sag or fracture under that same load over 12 months of continuous service.

Why “Strongest” Depends on Application Conditions

The “strongest” resin will fail prematurely if these three variables are ignored:

- Temperature: Most plastics lose significant stiffness as they approach their Glass Transition Temperature (Tg).

- Chemical Exposure: Harsh solvents can cause Stress Cracking, weakening the molecular bonds of otherwise “strong” plastics like Polycarbonate.

- UV Radiation: Prolonged sunlight exposure breaks down polymer chains, leading to surface embrittlement and loss of impact strength.

Top Strongest Plastics Used in Injection Molding

When selecting a high-strength polymer, you must choose between ultimate mechanical limits and economic feasibility. While PEEK offers the highest raw performance, reinforced engineering plastics like Glass-Filled Nylon provide sufficient strength for most industrial applications at a fraction of the cost.

Master Comparison Table: Tensile Strength, Impact, HDT, and Relative Cost

The following table provides the critical metrics engineers use to shortlist high-performance resins. Use these figures as a baseline for your initial material selection.

| Material | Tensile Strength (MPa) | Impact Strength (J/m) | HDT (°C @ 1.8MPa) | Cost Factor |

| PEEK (Unfilled) | 95 – 115 | 80 – 100 | 150 – 160 | $$$$$ |

| PPS (40% Glass-Filled) | 130 – 190 | 50 – 80 | 260 – 270 | $$$ |

| Nylon 66 (30% Glass-Filled) | 120 – 180 | 80 – 120 | 240 – 250 | $$ |

| Polycarbonate (PC) | 60 – 70 | 600 – 800 | 130 – 140 | $$ |

| Acetal (POM Homopolymer) | 70 – 80 | 50 – 70 | 120 – 135 | $ |

PEEK – Maximum Mechanical and Thermal Strength

PEEK (Polyether Ether Ketone) is the gold standard for metal replacement. It maintains a tensile strength of ~100 MPa and remains structurally stable at continuous temperatures exceeding 250°C. Its molecular stability makes it the only choice for parts that must survive high-pressure steam, radiation, or extreme mechanical loads in aerospace and medical implants.

PPS – Strength Under Heat and Chemical Exposure

PPS (Polyphenylene Sulfide) is chosen when chemical immunity is more critical than raw impact resistance. It features no known solvents below 200°C and maintains high rigidity in corrosive environments. While unfilled PPS is brittle, 40% glass-filled grades offer exceptional dimensional stability and a heat deflection temperature (HDT) that rivals PEEK at a significantly lower price point.

Glass-Filled Nylon (PA6/PA66 GF) – Strength-to-Cost Balance

Glass-Filled Nylon is the industry workhorse for structural parts. By adding 30% glass fibers, standard Nylon reaches 70–80% of the tensile strength of PEEK while costing only 20% as much. It is the go-to material for automotive engine covers, brackets, and power tool housings where high strength-to-cost efficiency is mandatory.

Polycarbonate – High Impact Strength

Polycarbonate (PC) is virtually unbreakable, offering impact resistance up to 250 times stronger than glass. While its tensile strength is lower than PEEK or reinforced Nylon, it excels in applications requiring optical clarity combined with extreme toughness.

Use PC for safety shields, helmets, and components that must survive sudden, high-velocity impacts without shattering.

Acetal (Delrin) – Strength with Dimensional Stability

Acetal (POM) provides the best fatigue resistance and lowest friction of any unreinforced plastic. It is uniquely capable of withstanding repetitive loading cycles without stretching or wearing down. Because it absorbs minimal moisture, it maintains its strength and precise dimensions in submerged or humid environments, making it ideal for precision gears and fuel system components.

Strength Comparison by Real-World Performance

To select the correct resin, you must rank materials based on the specific stress your part will encounter. General strength ratings often fail in specialized environments; use these data-driven rankings to narrow your selection.

Highest Tensile Strength Plastics

These materials offer the highest resistance to permanent deformation and snapping under tension.

- Rank 1: Carbon-Fiber Reinforced PEEK (approx. 220+ MPa)

- Rank 2: Glass-Filled PPS (approx. 130–190 MPa)

- Rank 3: Glass-Filled Nylon 66 (approx. 120–180 MPa)

- Rank 4: PEI (Ultem) (approx. 105–115 MPa)

Best Impact-Resistant Plastics

Measured by Izod Notched Impact tests, these resins absorb the most energy before fracturing.

- Rank 1: Polycarbonate (PC) – The industry leader for shatter-resistance.

- Rank 2: Long-Fiber Reinforced Nylon – Superior to standard short-fiber grades.

- Rank 3: ABS (High-Impact Grades) – Excellent for consumer-grade durability.

- Rank 4: PEEK – High toughness, but notch-sensitive compared to PC.

Best Creep and Fatigue Resistance

These materials maintain their shape under constant stress or repetitive cycling.

- Rank 1: Acetal (POM) – Best for cyclic fatigue (gears and springs).

- Rank 2: PEEK – Exceptional resistance to long-term creep at high temperatures.

- Rank 3: PPS – High dimensional stability under constant thermal load.

Best Strength at Elevated Temperatures (including HDT ratings)

Material strength drops sharply as temperatures rise. The Heat Deflection Temperature (HDT) indicates the point where the material loses its structural rigidity.

- PPS (Glass-Filled): 260°C – Maintains 50% strength at extreme heats.

- PEEK: 150°C (Unfilled) / 280°C (Glass-Filled).

- PEI (Ultem): 200°C – High strength without needing reinforcements.

- Nylon 66 (GF): 240°C – However, strength degrades if exposed to moisture at these temps.

Fiber-Reinforced Plastics: When Base Polymers Are Not Enough

Base resins often reach a physical “ceiling” where they can no longer support extreme loads. By integrating glass or carbon fibers, manufacturers transform standard polymers into structural composites capable of competing with die-cast metals. These reinforcements act as the “skeleton” of the part, absorbing the bulk of the mechanical stress.

Glass-Fiber vs. Carbon-Fiber Reinforcement

The choice between glass and carbon depends entirely on your stiffness-to-cost requirements.

- Glass-Fiber (GF): The industry standard for cost-effectiveness. Adding glass fibers significantly increases tensile strength and HDT. It is ideal for high-volume automotive and industrial parts where budget is a primary constraint.

- Carbon-Fiber (CF): The premium choice for maximum stiffness and weight reduction. Carbon fibers provide significantly higher flexural modulus (rigidity) than glass. Furthermore, carbon-filled parts are lighter and offer electrical conductivity, which is critical for EMI/RFI shielding in aerospace electronics.

Trade-Offs: Strength vs Brittleness vs Mold Wear

Increasing fiber content is not a “more is better” scenario. Engineers must manage the following technical trade-offs:

- Increased Brittleness: While fibers increase strength, they reduce elongation at break. A 50% glass-filled part will be incredibly stiff but may snap rather than bend under a sudden shock.

- The “Sweet Spot”: For most structural applications, a 30% to 40% fiber load provides the optimal balance of increased strength without making the part too brittle for assembly.

- Tooling Erosion: Fiber-reinforced resins are highly abrasive. Processing these materials requires hardened steel molds (typically H13 or D2 steel) to prevent the fibers from “scrubbing” the mold surface and ruining the part’s dimensional tolerances over time.

Strongest Plastic Based on Industry Use Case

Selecting the “strongest” plastic requires matching the material’s specific resistance profile to the unique stresses of the industry environment.

Automotive Structural Components

Under-the-hood environments demand materials that resist creep under high heat and exposure to corrosive fluids.

- Top Recommendation: 30-35% Glass-Filled Nylon (PA66 GF35). It is the industry standard for intake manifolds and engine covers because it maintains structural integrity at 150°C and resists engine oils.

- Alternative: PPS, if the component is located near the exhaust or requires higher chemical immunity.

Aerospace and High-Temperature Applications

In aerospace, strength is secondary to Specific Strength (weight reduction) and FST (Flame, Smoke, and Toxicity) compliance.

- Top Recommendation: Carbon-Filled PEEK. It replaces titanium and aluminum in bracketry and fasteners, offering extreme rigidity while being 60% lighter than steel.

- Alternative: PEI (Ultem), which provides inherent flame retardancy and high strength for interior cabin structures and electrical housings.

Industrial Gears, Bearings, and Load Parts

For moving parts, “strength” refers to wear resistance and the ability to maintain shape under constant friction.

- Top Recommendation: Acetal (POM). Known for its high hardness and “natural lubricity,” it prevents gear teeth from shearing or wearing down over millions of cycles.

- Alternative: Long-Fiber Reinforced Nylon for high-load industrial pulleys that require extreme impact toughness.

Medical and Precision Components

Strength in medical devices often requires the ability to survive repeated sterilization (autoclaving) without losing mechanical properties.

- Top Recommendation: Medical-Grade PEEK. It is biocompatible and survives thousands of sterilization cycles while maintaining the stiffness required for surgical instruments.

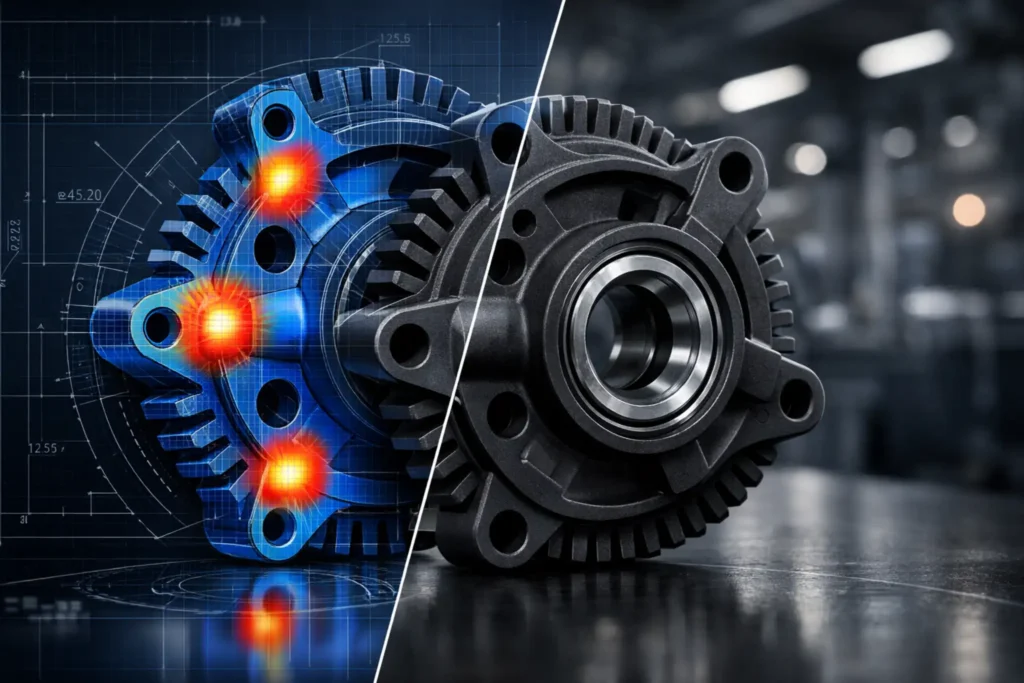

Processing Limits That Affect Strength

The theoretical strength listed on a material data sheet often differs from the actual strength of your molded part. Even the strongest polymers fail if the injection molding process is not optimized to manage molecular alignment and internal stresses.

Injection Pressure and Mold Design Impact

Achieving maximum strength requires high packing pressure. Low injection pressure leads to microscopic voids and poor molecular density, significantly reducing load-bearing capacity.

- Optimal Packing: Proper pressure ensures the polymer chains are compressed tightly, maximizing the material’s density and its ability to resist deformation.

- Wall Thickness: Inconsistent wall thickness causes uneven cooling, which creates internal “voids” that act as failure points under stress.

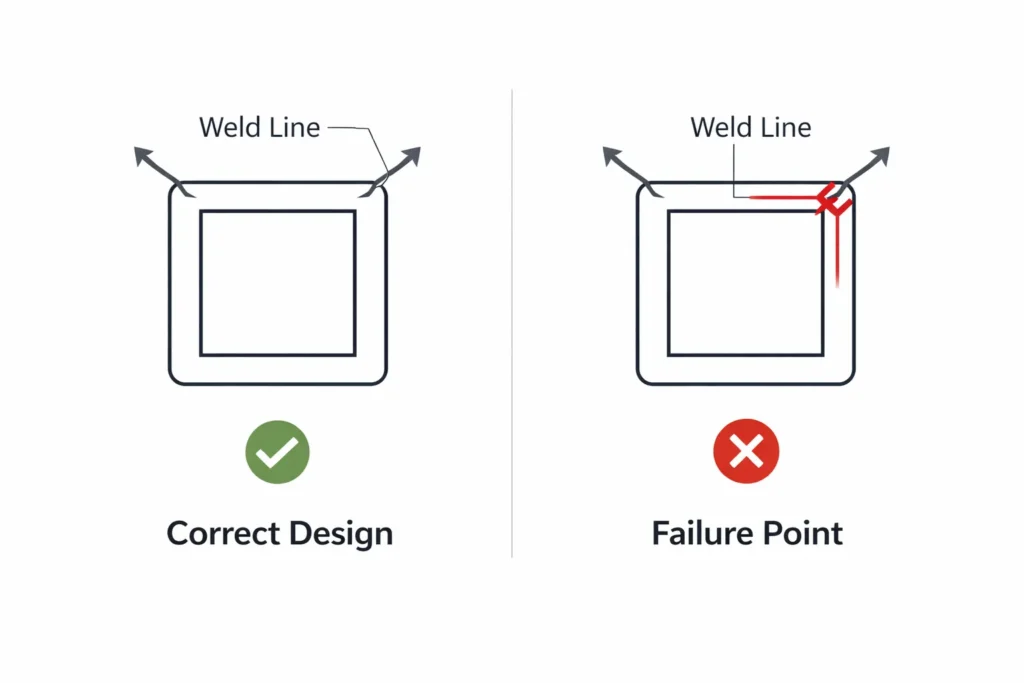

Fiber Orientation and Weld Line Weakness

A weld line occurs where two flow fronts meet, usually after flowing around a hole or core pin. This interface is the weakest point in any part.

- The Risk: In reinforced plastics, fibers do not cross the weld line, meaning the area relies solely on the base resin’s bond. This can cause a 40% to 60% drop in tensile strength at the seam.

- The Solution: Engineers must use Moldflow Analysis to move weld lines to non-load-bearing areas of the design.

Post-Molding Conditioning and Annealing

High-performance plastics like PEEK and PPS often retain internal residual stresses from the rapid cooling process in the mold.

- Annealing: This process involves heating the part to a specific temperature for a set duration to “relax” the polymer chains.

- Result: Proper Annealing improves dimensional stability and prevents environmental stress cracking, ensuring the part reaches its maximum theoretical strength.

Cost vs Strength: Selecting the Right Material

Maximizing performance while minimizing cost is the hallmark of superior engineering. Over-specifying a material like PEEK for a basic structural application is a common, expensive mistake that adds zero functional value.

Ultra-High Strength vs Economic Feasibility

Engineering is the art of balancing performance requirements against unit cost. While PEEK is objectively the “strongest” unreinforced plastic, its price can be 30 to 50 times higher than standard engineering resins.

To maintain economic feasibility, you must distinguish between “desired strength” and “required strength.” Using an ultra-high-strength polymer where a reinforced commodity plastic suffices leads to “over-engineering,” which can jeopardize a project’s financial viability.

When Nylon or Acetal Is Strong Enough

For the vast majority of industrial and consumer applications, Nylon (PA) and Acetal (POM) are the optimal choices.

- General Structural Loads: If your part operates at room temperature and requires high toughness, Nylon 6/6 is the industry standard.

- Dynamic Motion: If the “strength” required is actually resistance to wear and fatigue in gears or sliders, Acetal is superior and more cost-effective than PEEK.

- The Threshold: If your continuous operating temperature is under 100°C and the environment is not chemically aggressive, these materials offer the best strength-per-dollar ratio.

When PEEK or PPS Is Justified

The high price of PEEK or PPS is only justified when failure is not an option in extreme environments.

- The “Triple Threat”: Use these resins when the part faces high heat (>150°C), heavy mechanical load, and chemical exposure simultaneously.

- Metal Replacement: When you must match the strength of aluminum or steel while reducing weight by 50% for aerospace or medical implants, the performance of PEEK becomes a necessity, not a luxury.

- Dimensional Stability: PPS is the justified choice for high-precision components that must not expand or contract, even when submerged in hot automotive fluids or industrial solvents.

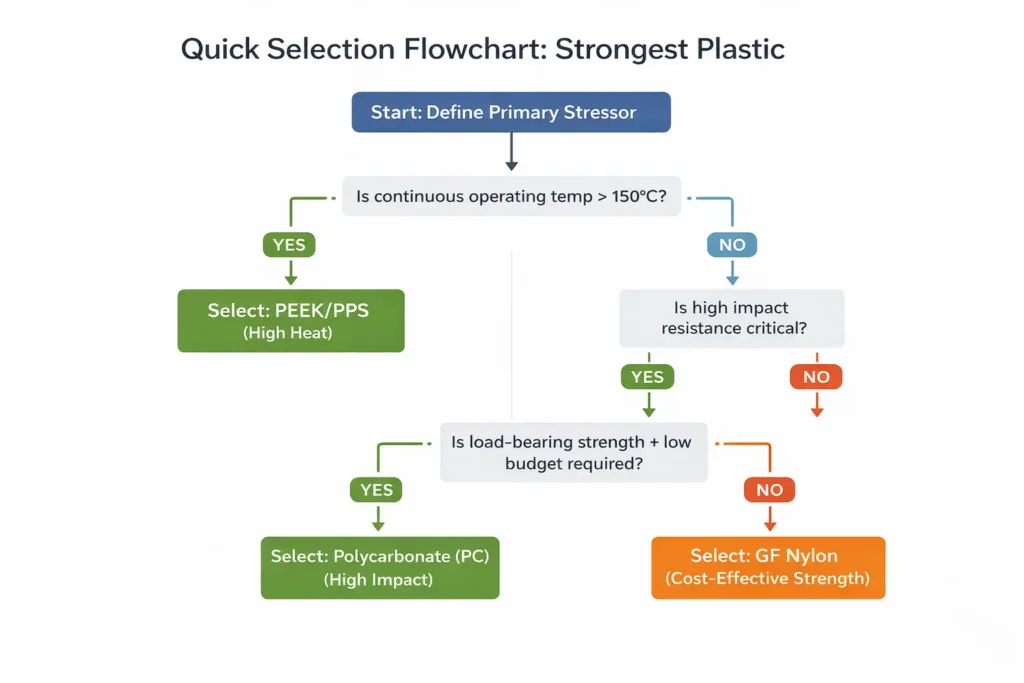

Final Recommendation: Choosing the Strongest Plastic for Your Part

Selecting the strongest plastic requires a pragmatic look at your part’s environment. Use this framework to finalize your material selection and avoid costly manufacturing errors.

Quick Selection Matrix by Load, Heat, and Budget

To identify your ideal resin, answer these three critical questions regarding your part’s primary stressor:

- Is it extreme heat (>150°C) with mechanical load?

- Selection: PEEK or PPS. These maintain structural integrity where others melt.

- Is it high impact or a sudden shock hazard?

- Selection: Polycarbonate (PC). It offers the highest energy absorption to prevent shattering.

- Is it high structural load on a restricted budget?

- Selection: Glass-Filled Nylon (PA66 GF). It provides the best “strength-per-dollar” for industrial frames.

Common Material Selection Mistakes to Avoid

Even the best material will fail if these factors are overlooked:

- Over-Specifying: Choosing PEEK when Glass-Filled Nylon suffices can increase part costs by 500% with no functional gain.

- Ignoring UV Degradation: High-strength resins like Polycarbonate become brittle and crack if used outdoors without UV stabilizers.

- Weld Line Placement: Neglecting Weld Line location during mold design can create a “hidden” weak point that fails at 50% of the rated load.

- Neglecting Chemical Compatibility: Using Polycarbonate near harsh industrial degreasers often leads to instant stress cracking.

FAQs:

Which specific plastic is the absolute strongest for injection molding applications?

The single strongest plastic is typically PEEK (Polyether Ether Ketone) when considering overall tensile strength and thermal resistance. When reinforced with carbon fiber, PEEK can reach tensile strengths over 200 MPa, outperforming many common metals. However, the “strongest” depends entirely on whether you prioritize tensile strength, impact resistance, or long-term creep performance.

Is PEEK stronger than metal, like steel or aluminum?

PEEK is rarely stronger than steel in raw tensile strength, but it often excels in specific strength (strength-to-weight ratio). PEEK is roughly half the weight of aluminum alloys and can offer comparable or superior load-bearing capacity and chemical resistance at elevated temperatures, making it a viable metal replacement option in aerospace and medical applications.

How much strength is lost at a “weld line” in an injection molded part?

A significant amount of strength is lost at a weld line, the point where two streams of flowing plastic meet during molding. For fiber-reinforced plastics, this can result in a 40% to 60% reduction in tensile strength because the fibers do not cross-link the seam. Mold designers must strategically place these lines in low-stress areas to prevent premature part failure.

When should I use glass-filled nylon instead of PEEK to save money?

Use glass-filled nylon when your operating environment is below 100°C and does not involve aggressive chemicals. Nylon 66 (30% GF) offers roughly 70-80% of PEEK’s tensile strength at just 20% of the cost, providing the best strength-to-cost balance for typical industrial applications.