Vapor Smoothing Nylon: Methods, Limits, and When It Actually Works

This guide provides an objective analysis of chemical vapor smoothing for PA11 and PA12 nylon, detailing precise roughness metrics, safety protocols, and mechanical impacts.

Direct Answer: Can Nylon Be Vapor Smoothed?

Yes, nylon can be vapor smoothed, but it requires specific industrial solvents, primarily formic acid blends rather than common hobbyist chemicals.

Unlike ABS or ASA, nylon is chemically resistant to acetone, which will not soften the surface. The process goes beyond aesthetics; while it creates a semi-gloss, injection-molded look, its primary engineering value lies in functional sealing. It transforms porous SLS or MJF surfaces into airtight, watertight, and biocompatible barriers by fusing the outer polymer chains into a homogenous layer.

The Verdict

- Compatible Solvents: Formic acid, acetic acid blends (proprietary).

- Incompatible: Acetone, IPA, or Ethyl Acetate (Zero effect on Nylon).

- Primary Benefit: High-gloss finish + 100% surface sealing for fluid-handling.

- Equipment Required: Closed-loop industrial vacuum chambers (e.g., AMT or DyeMansion).

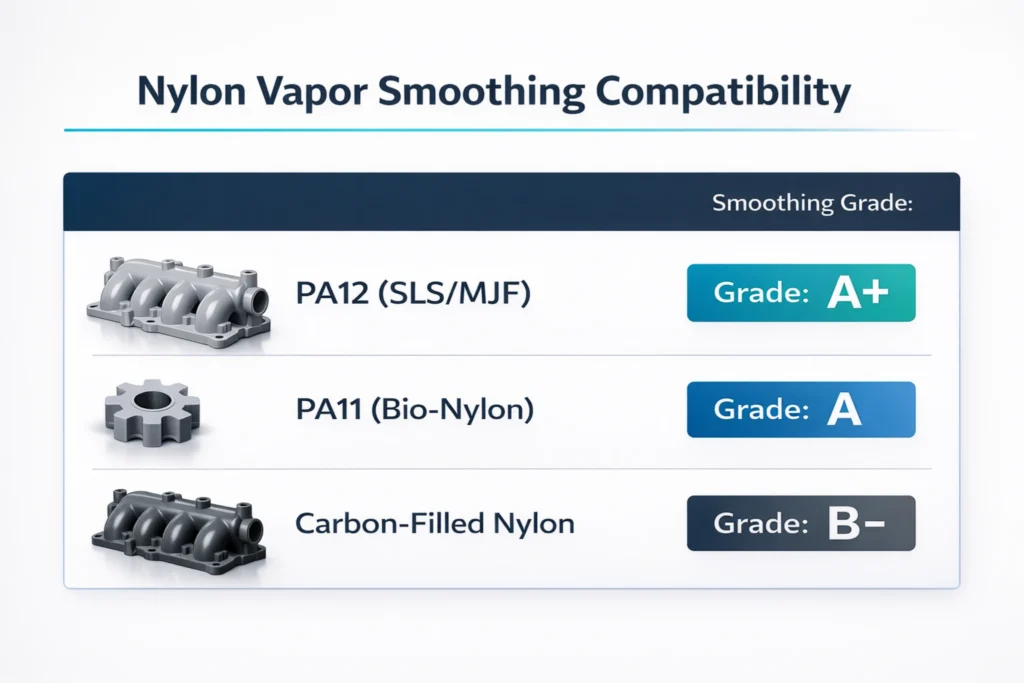

Which Nylon Types Respond to Vapor Smoothing

Nylon chemistry varies significantly across 3D printing technologies. While PA12 is the industry standard for vapor smoothing, other variants respond differently based on their molecular structure and additives.

| Nylon Type | Compatibility | Visual Result | Impact on Strength |

| PA12 (SLS/MJF) | Excellent | High Gloss / Semi-Gloss | Increased Elongation |

| PA11 | High | Consistent Satin Finish | Improved Impact Resistance |

| Nylon 6 (FDM) | Moderate | Variable Gloss | Negligible Change |

| Glass-Filled | Partial | “Pebbled” / Matte-Gloss Mix | No Change |

| Carbon-Filled | Partial | Textured / Dark Matte | No Change |

Nylon 12 and PA11 (SLS & MJF parts)

These materials are the ideal candidates for vapor smoothing. Because SLS and MJF parts are naturally porous, the solvent penetrates slightly deeper, creating a perfectly homogenous skin. PA12 achieves the most mirror-like finish, while PA11 maintains its superior impact resistance while becoming significantly easier to clean and sterilize.

Nylon 6 and Nylon 6/6 (why results differ)

Nylon 6 is more hygroscopic than PA12. If the part is not fully dehydrated before processing, the vapor smoothing can cause internal bubbling or surface clouding. While it can be smoothed, the results are less predictable than powder-bed parts, and dimensional stability is harder to maintain due to greater sensitivity to the thermal-solvent cycle.

Glass-filled and carbon-filled nylons (limitations)

Filled nylon materials create a unique aesthetic limitation. The solvent only reacts with the nylon polymer matrix; it cannot melt the glass beads or carbon fibers. As the nylon resin smooths and recedes, the fibers/beads become more prominent, resulting in a pebbled texture rather than a smooth plane. It effectively seals the part but will not achieve a high-gloss finish.

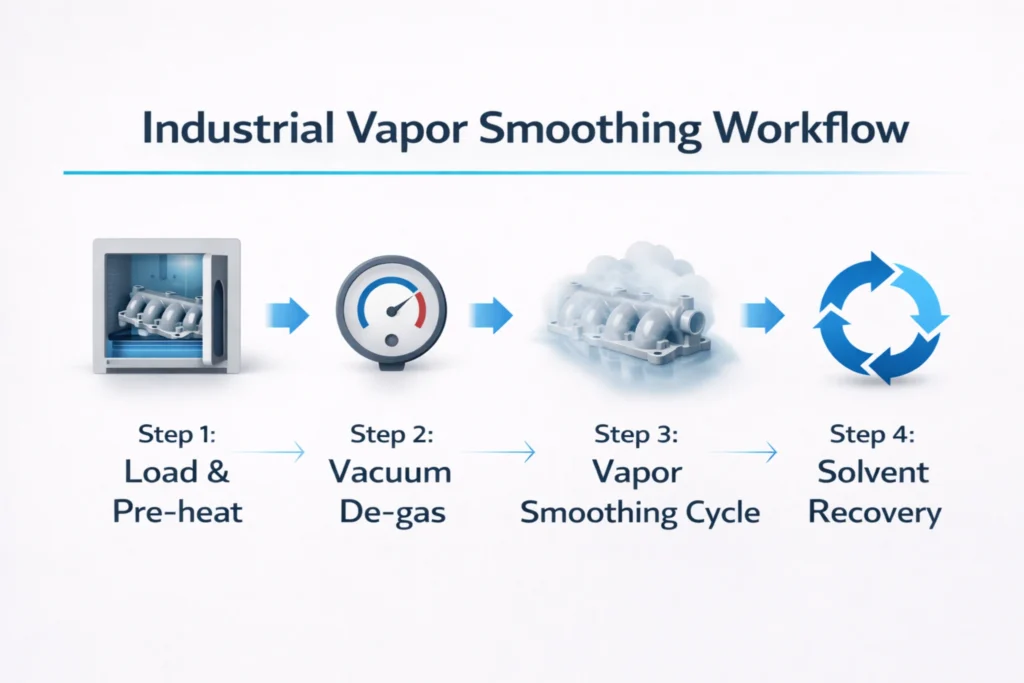

Vapor Smoothing Processes Used for Nylon

Nylon requires a sophisticated physicochemical approach to achieve a uniform finish. Unlike lower-temperature plastics, nylon’s chemical resistance and high melting point require a tightly controlled environment where temperature, pressure, and solvent concentration are precisely controlled.

Chemical Vapor vs. Thermal Smoothing

Thermal smoothing (using only heat) is insufficient for nylon; it often leads to part warping or loss of fine detail before the surface begins to flow.

The industry standard is physicochemical smoothing, which uses a specialized solvent vapor to lower the polymer’s glass transition temperature (Tg).

This allows the outer “skin” to liquify and redistribute via surface tension at temperatures far below the part’s structural melting point, preserving dimensional integrity.

Leading Industrial Systems: AMT PostPro vs. DyeMansion Powerfuse

For professional-grade results, two systems dominate the market:

- AMT PostPro SFX: Utilizes a proprietary “Boundary Layer Influence” technology. It is highly regarded for its ability to smooth complex internal geometries and channels without degrading mechanical properties.

- DyeMansion Powerfuse S: Uses a closed-loop system with the “Vapor Fuse Surfacing” (VFS) method. It is optimized for high-volume production and uses an eco-friendly solvent that is unregulated for transport, a major logistics advantage.

The Danger of DIY Approaches

Warning: DIY nylon vapor smoothing is hazardous. Nylon-compatible solvents, such as Formic Acid, are highly corrosive and toxic.

- Toxicity: Exposure can cause severe respiratory damage and chemical burns.

- Inefficiency: Without a vacuum-sealed, closed-loop system, the solvent evaporates unevenly, leading to “pitting” or soft spots.

- Risk: Professional machines recover 99% of the solvent; DIY setups release VOCs into the environment, creating a significant fire and health risk.

Do not attempt nylon vapor smoothing outside of a controlled industrial environment.

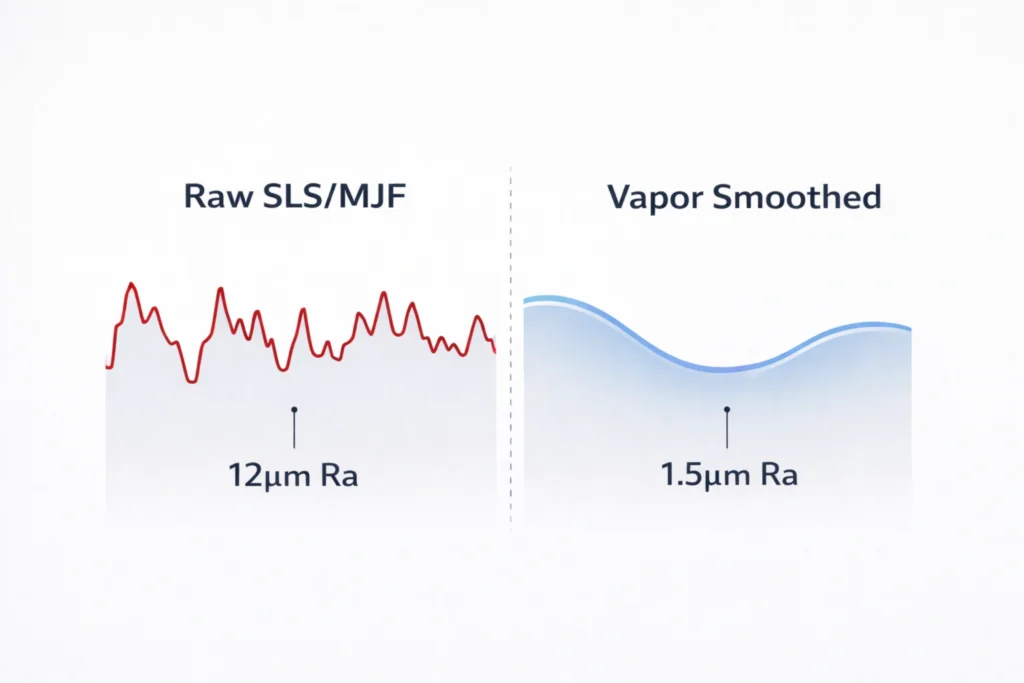

Surface Finish Results You Can Expect

Vapor smoothing delivers a predictable, repeatable finish that transforms the tactile and visual quality of nylon. While the aesthetic change is immediate, the quantitative improvements in surface topography are what make the process viable for engineering.

Roughness reduction and visual improvement

Vapor smoothing provides the most dramatic reduction in Surface Roughness (Ra) of any non-mechanical process.

- Performance: Expect a 70–80% reduction in measurable roughness.

- Typical Metrics: An as-printed MJF or SLS part usually measures 10–15μm Ra. After a standard smoothing cycle, this drops to 2μm Ra, achieving a finish comparable to 600-grit manual sanding but with total uniformity.

Edge definition and detail loss risk

Because the process works by “melting” the surface peaks, a slight loss of sharpness is inevitable.

- Threshold: Expect a 0.1mm–0.2mm rounding on sharp external corners.

- Recommendation: If sharp edges are critical for assembly, designers should compensate by adding a slight oversize offset or using “sacrificial” geometry in the CAD model.

Dimensional change and tolerance impact

Unlike abrasive tumbling or manual sanding, vapor smoothing removes almost zero material.

- Stability: Dimensional changes are typically minimal (<0.1%).

- Precision: Because the solvent penetration is controlled via vacuum pressure, it is far more precise than manual finishing. It is the preferred choice for complex internal geometries that traditional tools cannot reach.

Mechanical and Material Property Impact

Beyond aesthetics, vapor smoothing fundamentally alters the surface integrity of nylon parts. For engineers, the primary benefit is the transition from a porous, granular structure to a solid, homogenous polymer skin.

Strength, fatigue, and anisotropy changes

Vapor smoothing significantly enhances part durability by removing surface crack initiators. In as-printed SLS or MJF parts, the “peaks and valleys” of layer lines act as stress concentrators.

- Ductility: By smoothing these microscopic notches, the process increases elongation at break. This makes parts more flexible and less prone to brittle failure under load.

- Tensile Strength: Data from AMT confirms that vapor smoothing does not significantly lower tensile strength. The core of the part remains unaffected, while the outer shell becomes a toughened, consolidated layer.

Sealing, porosity reduction, and leak resistance

Raw 3D-printed nylon is naturally porous and prone to “wicking”, the absorption of liquids into the part’s core.

- 100% Sealed: Vapor smoothing fuses surface pores, making parts completely watertight and airtight. This is critical for manifolds, tanks, and pressure-rated components.

- Contamination Resistance: By eliminating porosity, parts become biocompatible and easy to sterilize, as bacteria and oils can no longer lodge in the surface grain. This is a primary requirement for medical-grade nylon applications.

Safety, Environmental, and Regulatory Considerations

Vapor smoothing nylon involves aggressive chemicals that require strict adherence to safety protocols. Operating within an industrial framework ensures both operator safety and environmental compliance.

Chemical handling and VOC exposure risks

The solvents used, such as formic acid, are volatile organic compounds (VOCs) that pose significant respiratory risks.

- Compliance: Facilities must adhere to OSHA PEL (Permissible Exposure Limits) to prevent long-term health issues.

- Containment: Industrial machines utilize closed-loop vacuum systems to prevent vapor escape. Never operate these processes without active carbon filtration and localized exhaust ventilation.

Regulatory Standards for Medical and Food Contact

For specialized industries, vapor smoothing is a regulatory “enabler.”

- Biocompatibility: Smoothing is often required to meet USP Class VI or ISO 10993 standards. Sealing surface pores, it prevents the entrapment of pathogens and facilitates effective sterilization.

- Environmental Impact: Modern systems like the DyeMansion Powerfuse S use solvents that are fully recoverable, significantly reducing the environmental footprint compared to traditional chemical dipping.

Vapor Smoothing vs Alternative Nylon Finishing Methods

While vapor smoothing provides a premium finish, engineers often consider mechanical or additive alternatives based on budget and part geometry.

Tumbling and bead blasting

These are the most common mechanical finishing methods for nylon.

- Bead Blasting: Uses high-pressure media to remove unsintered powder. It is fast and inexpensive but purely “line-of-sight.” It does not improve surface porosity or seal the part.

- Vibratory Tumbling: Parts rotate in abrasive media for 4–24 hours. This achieves a uniform matte finish and is highly cost-effective for large batches. However, it cannot reach internal channels and aggressively rounds sharp external edges.

Dyeing, coating, and infiltration

These processes add material or color rather than reshaping the surface.

- Dyeing: Essential for MJF or SLS parts to achieve a deep black or vibrant color. Unlike vapor smoothing, dyeing does not change the texture; it only changes the color.

- Infiltration: Involves dipping parts in resin (like cyanoacrylate or epoxy). This seals the part and adds strength, but results in unpredictable dimensional changes and a messy, inconsistent finish compared to the precision of vapor.

Machining and manual finishing

- CNC Machining: Used when critical tolerances (e.g., +/- 0.01mm) are required for bearing seats or mating surfaces. It is highly precise but expensive.

- Manual Sanding: Only viable for low-volume hobbyist work. It is labor-intensive, creates harmful nylon dust, and is impossible to perform uniformly on complex organic geometries.

When Vapor Smoothing Is the Right Choice

Vapor smoothing is not a luxury; it is a technical requirement for nylon parts that must perform in demanding environments. If your application requires more than just “visual appeal,” this process is often the only way to meet industrial specifications.

Functional parts and fluid-handling components

For engineers, the most compelling reason to use vapor smoothing is to eliminate porosity.

- Leak-Proof Performance: Raw SLS and MJF nylon act like sponges. Vapor smoothing creates a gas-tight and liquid-tight seal, making it the “gold standard” for fuel tanks, hydraulic manifolds, and cooling ducts.

- Pressure Resistance: By consolidating the surface, the part can better withstand internal pressures without weeping or structural weeping.

- Chemical Resistance: A sealed surface reduces the total surface area exposed to aggressive chemicals, significantly extending the service life of nylon components in automotive or industrial settings.

Cosmetic and consumer-facing applications

When a 3D-printed part needs to look and feel like an injection-molded product, vapor smoothing is the superior choice.

- Tactile Quality: It removes the “powdery” or “scratchy” feel typical of nylon prints, replacing it with a smooth, premium touch.

- Post-Processing Base: If you plan to paint or plate your parts, vapor smoothing provides a perfectly non-porous substrate. This prevents the “sink-in” effect, where paint is absorbed into the part, resulting in a much higher-quality final finish with fewer coats.

- Easy Sterilization: In medical or food-contact settings, the smooth surface prevents bacterial growth and allows for wipe-down sterilization, which is impossible on raw, porous nylon.

When Vapor Smoothing Should Be Avoided

While transformative, vapor smoothing is not a universal solution. Certain engineering requirements and material compositions can be adversely affected by chemical liquefaction of the surface.

Tight-tolerance and load-bearing parts

Vapor smoothing can compromise parts that require micrometer-level precision.

- Press-Fits and Threads: The process causes a slight “slumping” of sharp peaks. This rounding, typically 0.1mm to 0.2mm, can ruin tight-tolerance press-fits or fine-pitch internal threads.

- Load-Bearing Interfaces: For parts that rely on specific surface friction or precise mating planes for load distribution, the transition to a glossy, reduced-friction surface may lead to mechanical slippage or misalignment. If a part requires high-precision bearing seats, these areas should be masked or machined after smoothing.

Heat-sensitive or fiber-reinforced nylons

Not all nylon composites react favorably to the thermal-solvent cycle.

- Fiber-Reinforced (Carbon/Glass): In materials like PA12-CF or PA11-GF, the solvent only affects the nylon matrix. As the resin smooths, the fibers remain rigid, often protruding and creating a sandpaper-like texture rather than a smooth finish. This can actually decrease the aesthetic quality.

- Thin-Walled Geometry: Parts with wall thicknesses below 0.8mm are at high risk of warping or collapsing. Localized surface melting reduces structural rigidity during the “tack” phase of the process, potentially leading to permanent deformation in delicate or heat-sensitive geometries.

Selection Checklist for Engineers and Print Shops

Deciding whether to integrate vapor smoothing into your workflow depends on your production volume and the complexity of your performance requirements. Use this checklist to determine your path forward.

Material, geometry, and volume considerations

- High-Volume Production: If your facility processes more than 500 nylon parts per month, investing in in-house equipment becomes mathematically sound. It grants you total control over lead times and finish consistency.

- Low-Volume or Complex R&D: For prototypes or small batches, use a service bureau. This avoids the massive overhead of chemical management and regulatory compliance.

- Geometry Check: If your part contains internal lattices or complex fluid channels that require sealing, vapor smoothing is non-negotiable over mechanical tumbling.

Cost-Benefit Analysis: Service Bureaus vs. In-House Equipment

The financial divide between in-house and outsourced smoothing is significant.

- In-House Equipment: Professional closed-loop systems like the AMT PostPro or DyeMansion Powerfuse S require a capital expenditure of $60,000–$100,000+. This does not include the cost of specialized solvents, hazardous waste disposal, and explosion-proof facility requirements.

- Service Bureaus: Outsourcing to providers like Xometry or Protolabs typically adds $15–$50 per part to your manufacturing cost.

The Bottom Line: Only transition to in-house smoothing if your annual outsourcing spend exceeds $40,000, or if your parts fall under strict ITAR or medical confidentiality requirements.

FAQs

Can you vapor-smooth Nylon with acetone?

No, acetone has zero effect on Nylon (PA11/PA12). Nylon is chemically resistant to acetone, which is typically used for ABS or ASA. Smoothing Nylon requires specialized industrial solvents such as formic acid or proprietary blends (e.g., FA 326), used in closed-loop systems.

How much does vapor smoothing Nylon cost?

For outsourcing, service bureaus typically charge $15 to $50 per part, depending on the size and complexity of the part. Purchasing an industrial vapor smoothing machine (like those from AMT or DyeMansion) starts at approximately $60,000 to $100,000+.

Does vapor smoothing make 3D-printed Nylon stronger?

Vapor smoothing primarily improves ductility rather than raw tensile strength. Removing surface layer lines that act as crack initiators can significantly increase elongation at break and impact resistance. It also creates a 100% airtight, watertight seal, preventing moisture absorption into porous SLS or MJF parts.

Is vapor smoothing Nylon safe to do at home?

DIY vapor smoothing for Nylon is not recommended. The necessary solvents, such as formic acid, are highly toxic, corrosive, and flammable. Industrial systems are “closed-loop,” meaning they recover 99% of vapors to prevent operator exposure and environmental contamination.

Which Nylon 3D printing materials work best with vapor smoothing?

Nylon 12 (PA12) and Nylon 11 (PA11) from SLS and MJF processes provide the most consistent, high-gloss results. Glass-filled or Carbon-filled Nylons can be sealed, but they will maintain a “pebbled” or matte texture because the solvent cannot melt the reinforcement fibers.