Will Polyester Shrink? What Really Happens When You Wash or Dry It

Polyester does not behave like natural fibers such as cotton or wool, and that difference is the source of most confusion around shrinking.

As a synthetic polymer, polyester reacts to heat and moisture in fundamentally different ways, which means changes in size are often mistaken for traditional shrinkage.

In real-world use, people frequently mix up shrinking, warping, melting, or permanent deformation because the visual result can look similar.

Understanding what polyester fibers are designed to do and what conditions push them beyond their limits makes it much easier to predict what will actually happen when you wash or dry polyester clothing.

Quick Answer Does Polyester Shrink or Not?

Polyester usually resists shrinking under normal washing conditions because it is designed to hold its shape.

When size changes do happen, heat not water is almost always the cause, especially during high dryer temperatures or very hot washes.

What many people call “shrinkage” is often permanent deformation or warping, where the fabric structure is altered rather than uniformly reduced.

This is why polyester can seem unpredictable if heat exposure isn’t controlled.

In short:

- Polyester typically does not shrink the way natural fibers do

- High heat is the primary risk factor

- Misshaping and true shrinkage are not the same thing

Why Polyester Usually Doesn’t Shrink Like Cotton

Polyester Fiber Structure Explained Simply

Polyester is a man made, thermoplastic fiber, meaning it is formed from long polymer chains that are created, shaped, and “set” using heat during manufacturing.

Once these chains cool, they lock into a stable structure, much like plastic molded into a fixed shape. Under normal conditions, those chains do not relax or tighten on their own.

Cotton behaves differently because it is made of cellulose, a natural material that absorbs water and swells. When cotton dries, its fibers contract and pull the fabric smaller.

Polyester does not absorb water in the same way, so its internal structure stays largely unchanged unless heat is high enough to soften those polymer chains.

Heat vs Water (What Actually Causes Polyester to Change Shape)

Water on its own does not cause polyester to shrink because the fiber does not absorb moisture into its structure.

Unlike natural fibers, polyester remains dimensionally stable when wet, even during extended wash cycles. This is why cold or warm water washing rarely changes the size of polyester garments.

Heat is the factor that matters because it can relax the polymer chains that were previously heat-set during manufacturing.

High dryer temperatures, prolonged steam exposure, or very hot wash cycles can soften those chains enough for the fabric to lose its original shape. When that happens, the result is usually warping or tightening in specific areas rather than even, predictable shrinkage.

When Polyester Can Shrink (Real World Situations)

The Shrinkage Threshold: When Heat Becomes a Problem

Polyester remains dimensionally stable at lower temperatures because its polymer chains stay locked in their heat-set position. In most garments, this stability holds below roughly 140°F (60°C), which covers cold and warm wash cycles and low heat drying.

At these levels, the fiber structure does not soften enough to change shape.

Problems begin in the 150–170°F (65–75°C) range and above, where heat can partially relax those chains.

Steam cycles are especially risky because steam transfers heat more efficiently than dry air, often exceeding safe limits even when the dryer setting sounds gentle.

Modern dryer modes labeled “Steam Refresh” or “Sanitize regularly” reach temperatures designed for odor or bacteria control, not fabric stability, which is why polyester deformation often happens there rather than during washing.

High Heat in the Dryer

Dryers expose polyester to a combination of hot air, mechanical tumbling, and friction against the drum. This creates localized overheating, where certain areas of a garment such as seams, folds, or thicker panels reach higher temperatures than the setting suggests.

Those hotspots are where polymer chains are most likely to relax and lose their original alignment.

Steam cycles increase this risk because moisture allows heat to penetrate fibers more efficiently. Even when a setting appears moderate, steam assisted modes often operate at higher effective temperatures than standard dry heat.

This is why polyester damage frequently shows up as uneven tightening or distortion rather than uniform size reduction.

Boiling or Very Hot Wash Cycles

Very hot or near boiling water rarely causes true polyester shrinkage on its own because the fiber does not respond to water the way natural materials do.

In isolation, a single hot wash is more likely to leave the garment unchanged in size. The risk increases when high water temperatures are combined with other heat sources.

Cumulative heat exposure matters more than any single step. Washing in very hot water followed by high heat or steam drying raises the fabric temperature past safe thresholds.

In most cases, the dryer not the wash cycle, is where permanent deformation actually occurs.

Low Quality or Poorly Finished Polyester

Polyester garments rely on proper heat setting during manufacturing to lock fibers into a stable shape. When this process is rushed or incomplete, the polymer chains are left under uneven tension. That tension makes the fabric more sensitive to later heat exposure.

In these cases, normal dryer temperatures that would be safe for well finished polyester can cause shape changes. The result is often irregular tightening, twisting, or puckering rather than uniform shrinkage. This behavior reflects manufacturing differences, not an inherent flaw in polyester as a material.

Will 100% Polyester Shrink or Only Blends?

Comparison Table: Shrinkage Percentages by Fabric Type

| 100% Polyester | 0–2% (often uneven) | Heat-induced deformation |

| Cotton–Polyester Blend | 3–5% | Cotton fiber contraction |

| Polyester–Spandex Blend | 2–6% (localized) | Heat damage to elastane |

Pro-Tip: If your tag says “60% Cotton / 40% Polyester,” treat it as a cotton garment. The natural fibers will always dominate the shrinkage profile.

The key difference is not whether polyester is present, but how other fibers behave under heat. Cotton naturally shrinks when washed and dried, so blends inherit that behavior even if polyester itself remains stable.

Spandex does not “shrink” in the classic sense, but it degrades under heat, which can pull fabric tighter in specific areas and create the appearance of shrinkage.

100% Polyester Garments

Pure polyester garments are designed to be dimensionally stable because the fibers are heat set into a fixed shape during manufacturing.

This process locks the polymer chains in place, allowing the fabric to maintain its size through normal washing and low heat drying. Under these conditions, measurable shrinkage is uncommon.

Problems arise only when temperatures exceed what the heat setting was designed to tolerate. Extreme heat can soften the fibers and allow sections of the garment to warp or tighten unevenly. This is a structural change, not the gradual, all over shrinkage seen in natural fabrics.

Polyester-Cotton and Polyester-Spandex Blends

Blended fabrics behave according to the combined response of each fiber, not polyester alone. Cotton fibers absorb water and contract as they dry, while polyester remains mostly unchanged. When blended, the cotton portion pulls the fabric tighter, creating overall size reduction even though polyester itself resists shrinking.

Polyester–spandex blends introduce a different risk. Spandex is highly sensitive to heat, and excessive temperatures can cause elastic snap or loss of recovery. When the elastic component degrades, it can draw surrounding fabric inward unevenly.

In practice, the weakest or most heat sensitive fiber determines how the garment changes, not the most stable one.

Does Polyester Shrink Permanently or Just Once?

Shrinking, Melting, or Warping? How to Identify Damage

True shrinkage means the entire garment becomes smaller in a relatively even way. With polyester, this outcome is uncommon and usually limited to blends where another fiber is doing the contracting.

When shrinkage does occur, it typically happens once, at the point where heat first exceeds safe limits.

Warping is more common and often mistaken for shrinkage. Here, the fabric’s shape changes unevenly because certain areas softened under heat while others did not.

Puckered or wavy seams are a classic sign, and they usually come from a mismatch between the sewing thread and the fabric. Many threads are polyester or cotton-poly blends that react differently to heat than the surrounding fabric, causing seams to tighten even when the garment’s overall size stays the same.

Melting is a separate and irreversible form of damage. At very high temperatures, polyester fibers can fuse, harden, or develop a glossy, brittle texture. Once this happens, the polymer structure has been permanently altered, and the garment cannot return to its original shape or feel.

Why Polyester Damage Is Often Irreversible

Polyester damage becomes permanent when heat relaxes the polymer chains beyond their original heat set position. Once those chains cool in a new alignment, the fabric stabilizes in that altered shape. Unlike natural fibers, polyester does not re-tighten or rebound when conditions return to normal.

This is why prevention matters more than correction. Staying below critical heat levels keeps the polymer structure unchanged, while repeated or extreme heat makes reversal unlikely. Understanding this behavior helps reduce mistakes rather than create concern about normal care.

Will Polyester Shrink in the Dryer?

Safe Dryer Temperatures for Polyester

Polyester tolerates dryers best when heat levels stay low enough to avoid softening the fiber structure.

Low heat or permanent press settings typically keep temperatures below the point where polymer chains begin to relax. Under these conditions, the fabric maintains its original dimensions.

Risk increases as temperatures rise or cycles extend.

Steam modes deserve special caution because they often exceed safe heat thresholds even when labeled as gentle.

Avoiding high heat and steam assisted programs is the most reliable way to prevent polyester from changing shape in the dryer.

Tumble Dry vs Air Dry (What’s Actually Best)

Tumble drying on low heat is generally safe for polyester because the fabric is designed to tolerate moderate, controlled temperatures.

This approach works well for everyday garments that need quick drying without extended heat exposure. When cycles are kept short and heat is limited, dimensional stability is usually maintained.

Air drying becomes preferable when garments are lightweight, blended with heat sensitive fibers, or have detailed seams and finishes. Removing heat entirely eliminates the risk of polymer relaxation. The best choice depends on fabric construction and dryer settings rather than a single universal rule.

How to Wash Polyester Without Shrinkage

Correct Water Temperature & Cycle Settings

Polyester remains stable in cold and warm water because moisture does not penetrate or alter its fiber structure. At these temperatures, the polymer chains stay locked in their heat-set position, so washing alone does not change garment size. This makes temperature control straightforward for most routine care.

Gentle or permanent press cycles add another layer of protection by reducing mechanical stress and friction. Lower agitation limits localized heat buildup and tension at seams. Together, moderate water temperature and gentle motion preserve the fabric’s original shape.

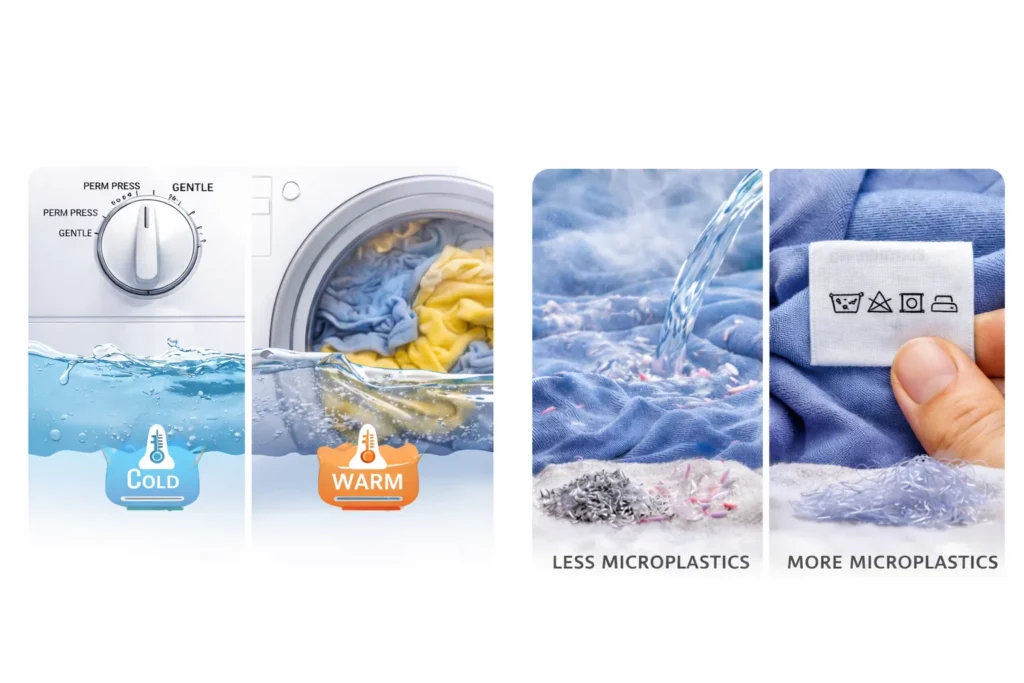

The “Cold Water” Win: Preventing Shrinkage and Microplastics

Cold water washing reduces stress on polyester fibers by keeping temperatures well below the point where polymer chains can relax.

When fibers remain structurally stable, they are less likely to weaken, distort, or break during agitation. This directly lowers the risk of shape changes over time.

Overheating and excessive friction increase fiber damage, which contributes to microplastic shedding as tiny fragments break away from the fabric surface.

Using cold water helps preserve fiber integrity, extending garment lifespan while reducing unnecessary fiber loss.

The benefit is practical first: longer-lasting clothing with fewer care-related problems.

Decoding Modern Care Labels

Care labels are designed to indicate maximum safe conditions, not guarantees against damage. Symbols for washing, drying, and ironing reflect the highest temperature or method the manufacturer believes the fabric can tolerate under controlled testing.

They do not account for variations in home machines or prolonged exposure.

Language such as “tumble dry low” or “warm wash” is intentionally conservative and often tied to liability rather than precision.

Vague labels should be treated as upper limits, not targets.

When settings are unclear, choosing lower heat and gentler cycles provides a wider margin of safety for polyester fabrics.

How to Dry Polyester Safely

Dryer Settings That Are Actually Safe

Polyester dries most reliably on low heat or permanent press settings, where temperatures stay below levels that soften the fiber structure.

Shorter cycles with moderate airflow reduce prolonged heat exposure while still removing moisture efficiently. This combination maintains fabric shape without unnecessary stress.

Steam assisted modes should be avoided unless a garment explicitly allows them.

These cycles often exceed safe heat thresholds and increase the risk of uneven deformation. When in doubt, lower heat is a safer choice than extended drying time.

When Air Drying Is the Better Choice

Air drying is a better option when garments are lightweight, blended with heat sensitive fibers, or have structured seams that are prone to distortion.

Removing heat entirely eliminates the main factor that causes polyester to change shape. This approach is especially useful for newer items where preserving the original fit matters.

It is also practical when drying time is not critical. Air drying trades speed for maximum stability, without implying that machine drying is inherently unsafe when settings are controlled.

Can You Unshrink Polyester If It Shrinks?

What Works, What Doesn’t, and Why

Options for reversing polyester shrinkage or deformation are limited because the change happens at the molecular level.

Once heat relaxes the polymer chains and they cool into a new position, the fabric stabilizes in that altered shape. Water, conditioners, or stretching techniques do not re-set those chains in a controlled way.

Gentle steaming or low-heat reshaping may slightly improve minor warping if the damage is minimal, but results are inconsistent.

Common “unshrinking” hacks work on natural fibers, not thermoplastics.

For polyester, prevention through controlled heat is far more reliable than correction after the fact.

When Damage Is Permanent

Polyester damage is permanent when heat exposure alters the fiber structure beyond its original setting. At that point, the fabric has stabilized in a new shape, and normal care methods cannot reverse it. This outcome is not sudden or unpredictable, but the result of exceeding known heat limits.

The practical takeaway is simple. Understanding how polyester responds to heat allows most issues to be avoided entirely. Consistent, moderate care prevents the conditions that lead to irreversible change.

When Polyester Shrinkage Is a Non-Issue

Performance Fabrics and Modern Polyester

Many modern polyester fabrics are engineered specifically to resist heat related deformation.

In athletic and outdoor textiles, fibers are tightly controlled, heat-set at higher tolerances, and often combined with finishes that improve dimensional stability. These materials are designed to perform under repeated washing and drying.

Because of this engineering, routine care rarely affects their size or shape.

While extreme heat can still cause damage, the margins of safety are wider than in basic fashion fabrics. For most performance garments, shrinkage concerns are minimal under standard care conditions.

Pre-Shrunk and Heat-Set Polyester

Heat-setting is the process that stabilizes polyester fibers by locking their polymer chains into a fixed configuration during manufacturing.

When garments are labeled as pre-shrunk or heat-set, this step has already been applied at controlled temperatures higher than normal home care. As a result, the fabric is conditioned to hold its shape.

This significantly reduces the likelihood of size changes during washing or drying. While no fabric is immune to extreme heat, properly heat-set polyester offers a predictable and stable performance in everyday use.

Final Verdict (Should You Worry About Polyester Shrinking)?

Polyester does not behave unpredictably once its material limits are understood.

The fiber is designed for stability, and most problems attributed to “shrinkage” come from heat levels that exceed what the fabric was set to tolerate. When care stays within those boundaries, size changes are uncommon.

The practical advantage of polyester is control. Unlike natural fibers that react automatically to water and drying, polyester responds mainly to heat. Knowing where that line is allows you to wash and dry with confidence rather than caution, focusing on consistency instead of concern.

Key Takeaways (Read This Before Washing)

- Polyester is structurally stable and does not react to water the way natural fibers do.

- Heat, not washing, is the primary factor that can alter polyester’s shape.

- Most size changes attributed to shrinkage are actually warping or deformation.

- Low heat and permanent press dryer settings stay within safe limits.

- Steam and sanitize cycles pose higher risk due to elevated temperatures.

- Blended fabrics follow the behavior of the most heat-sensitive fiber.

FAQs

Will polyester shrink in the dryer?

Polyester is more shrink resistant than natural fabrics like cotton, so it usually won’t shrink much. But it can shrink slightly, especially if it’s exposed to high heat or if it’s a polyester blend (like poly-cotton).

To avoid shrinkage:

- Use low heat or air-dry settings

- Remove items as soon as they’re dry (don’t over-dry)

- Check the care label for the safest temperature

Will 100 polyester shrink?

100% polyester is very unlikely to shrink, because it’s a synthetic fiber designed to hold its shape. However, it can shrink slightly if exposed to high heat especially in a hot dryer or during high-temperature washing.

To keep it from shrinking:

- Wash in cold or warm water (avoid hot)

- Dry on low heat or air-dry

- Don’t over-dry or leave it in high heat for long periods

Will 60 cotton 40 polyester shrink?

Yes, 60% cotton / 40% polyester can shrink, mainly because of the cotton.

- How much? Usually a little, but it can be noticeable especially on the first wash/dry.

- What causes it? Hot water + high dryer heat (cotton shrinks most under heat).

To minimize shrinkage:

- Wash in cold (or cool) water

- Dry on low heat or air-dry

- Remove while slightly damp and hang/lay flat to finish drying

How much will polyester shrink?

Polyester usually shrinks very little often 0–3% because it’s a heat-resistant synthetic fiber. If it’s exposed to high heat (hot wash + high dryer), it may shrink slightly more, especially in areas like length.

What affects shrinkage most:

- High dryer heat or over-drying

- Polyester blends (cotton blends shrink more)

- Tighter weaves/knits and cheaper finishes

To keep shrinkage near zero: wash cold and dry on low heat or air-dry.

Can I wash polyester at 60 degrees?

You can, but 60°C is usually too hot for polyester unless the care label specifically allows it. High heat can cause warping, pilling, fading, or slight shrinkage, and it may weaken the fabric over time.

Best practice:

- Wash polyester at 30–40°C for everyday cleaning

- Use 60°C only for items that need extra sanitation (like some towels or bedding) and only if the label permits

- If you do wash at 60°C, use a gentle cycle and avoid high-heat drying afterward

Does recycled polyester shrink?

Recycled polyester (rPET) generally doesn’t shrink much, just like regular polyester. It’s still a synthetic fiber, so it’s naturally shrink-resistant.

That said, slight shrinkage can happen if it’s exposed to high heat, especially:

- Hot washing (high temperatures)

- High-heat tumble drying

- If it’s a blend (like recycled poly + cotton), where the other fiber may shrink more

To prevent shrinkage: wash cold to warm, and dry on low heat or air-dry.